A Full Bridge and an H-Bridge are both types of motor driver circuits used to control the direction of a DC motor by switching the polarity of the voltage applied to the motor terminals. Your choice depends on the specific application requirements, as both topologies provide efficient bidirectional control but differ slightly in configuration and implementation.

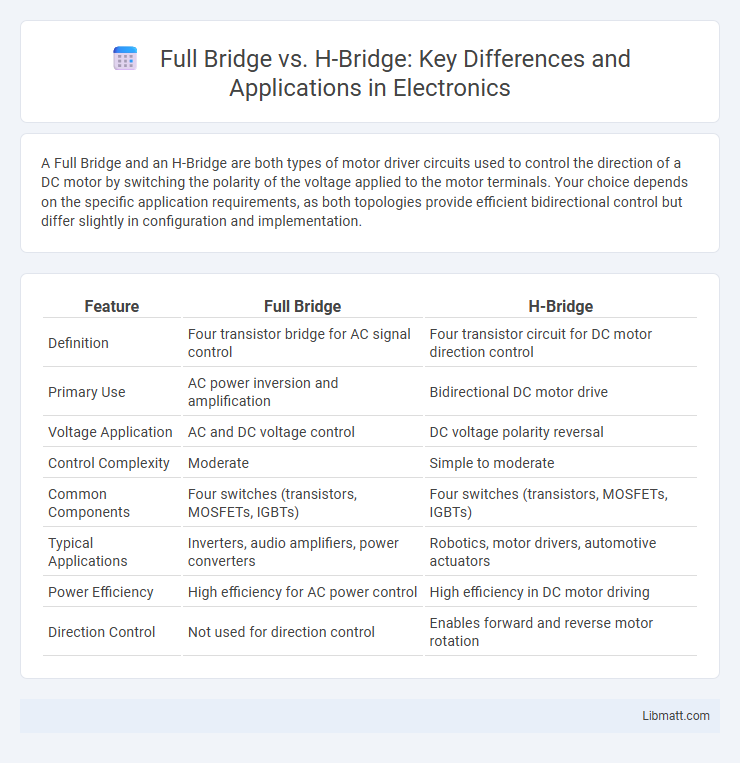

Table of Comparison

| Feature | Full Bridge | H-Bridge |

|---|---|---|

| Definition | Four transistor bridge for AC signal control | Four transistor circuit for DC motor direction control |

| Primary Use | AC power inversion and amplification | Bidirectional DC motor drive |

| Voltage Application | AC and DC voltage control | DC voltage polarity reversal |

| Control Complexity | Moderate | Simple to moderate |

| Common Components | Four switches (transistors, MOSFETs, IGBTs) | Four switches (transistors, MOSFETs, IGBTs) |

| Typical Applications | Inverters, audio amplifiers, power converters | Robotics, motor drivers, automotive actuators |

| Power Efficiency | High efficiency for AC power control | High efficiency in DC motor driving |

| Direction Control | Not used for direction control | Enables forward and reverse motor rotation |

Introduction to Bridge Circuits

Bridge circuits are essential components in power electronics used to control the direction and flow of current through a load. A Full Bridge circuit, also known as an H-Bridge, consists of four switching elements arranged in a configuration that allows bipolar voltage outputs, enabling precise bidirectional control of motors or actuators. These circuits are widely used in DC motor drivers, enabling efficient torque control and reversible rotation by manipulating the switching states of the transistors or MOSFETs within the bridge.

Understanding the Full Bridge Topology

Full Bridge topology consists of four switching elements arranged in a rectangular configuration, enabling current to flow in both directions through the load for bidirectional control. This configuration allows precise regulation of motors or actuators by reversing voltage polarity, enhancing control flexibility. Compared to an H-Bridge, the Full Bridge efficiently manages power delivery with minimal electrical noise and improved thermal distribution.

Overview of the H-Bridge Configuration

The H-Bridge configuration consists of four switches arranged in an "H" pattern to control the direction of current through a load such as a DC motor, enabling bidirectional rotation. This setup allows your motor to run forward, reverse, or be braked by selectively activating specific switches, making it ideal for precise motor control in robotics and automation. The design provides efficient voltage utilization and simple control logic compared to other motor driver circuits.

Key Differences Between Full Bridge and H-Bridge

A Full Bridge circuit typically consists of four switches arranged to control the direction and magnitude of current through a load, enabling efficient DC motor control. An H-Bridge is a specific type of Full Bridge configuration designed to allow voltage to be applied across a load in either direction, making it ideal for bidirectional motor driving. Your choice depends on application requirements, with H-Bridges providing greater control flexibility for reversing motor direction and Full Bridges being used in varying power electronics contexts.

Applications of Full Bridge Circuits

Full Bridge circuits are widely used in DC motor control, enabling efficient bidirectional motor operation in applications such as electric vehicles and robotics. They provide precise voltage control in power inverters for renewable energy systems and are essential in audio amplifiers to drive speakers with high power output. Your choice of a Full Bridge circuit ensures reliable performance in systems requiring controlled polarity reversal and optimized power delivery.

Typical Uses for H-Bridge Circuits

H-bridge circuits are commonly used in motor control applications, allowing bidirectional control of DC motors for robotics, electric vehicles, and automated machinery. They enable precise speed and direction adjustments by switching the polarity of the voltage applied to the motor. H-bridges are also integral in power inverters and DC-DC converters, where efficient polarity reversal and current flow management are essential.

Efficiency and Performance Comparison

Full Bridge and H-Bridge circuits deliver similar efficiency levels, with both enabling bidirectional current flow for motor control. The H-Bridge design typically offers better performance in switching speed and thermal management due to its configuration of four switches, which reduces power loss and heat generation. Efficiency in both depends on component quality and switching frequency, but the H-Bridge is often preferred in applications requiring precise speed and torque control.

Cost and Component Considerations

Full Bridge configurations typically require fewer components than H-Bridges, resulting in lower overall cost and simplified assembly. However, H-Bridges provide more precise control and functionality at the expense of additional components and a higher price point. Your choice depends on balancing budget constraints with desired performance and component availability.

Choosing the Right Bridge for Your Project

Full Bridge and H-Bridge circuits offer effective methods for controlling DC motors by enabling bidirectional current flow, but choosing the right bridge depends on your project's voltage, current requirements, and switching speed. Full Bridge configurations are typically simpler and suitable for low-power applications, while H-Bridges provide more flexibility with PWM control and higher efficiency in medium to high-power systems. Your selection should prioritize matching bridge topology with your motor specifications and control strategy to optimize performance and reliability.

Conclusion: Full Bridge vs H-Bridge Summary

The Full Bridge and H-Bridge configurations both efficiently control DC motors by enabling reversible current flow through the motor windings. Full Bridge circuits are typically used in signal processing and power amplification, while H-Bridges are specifically designed for motor control applications, offering bidirectional motor control with four switching elements. Your choice depends on whether you need precise motor direction control (H-Bridge) or general full-wave signal modulation (Full Bridge).

Full Bridge vs H-Bridge Infographic

libmatt.com

libmatt.com