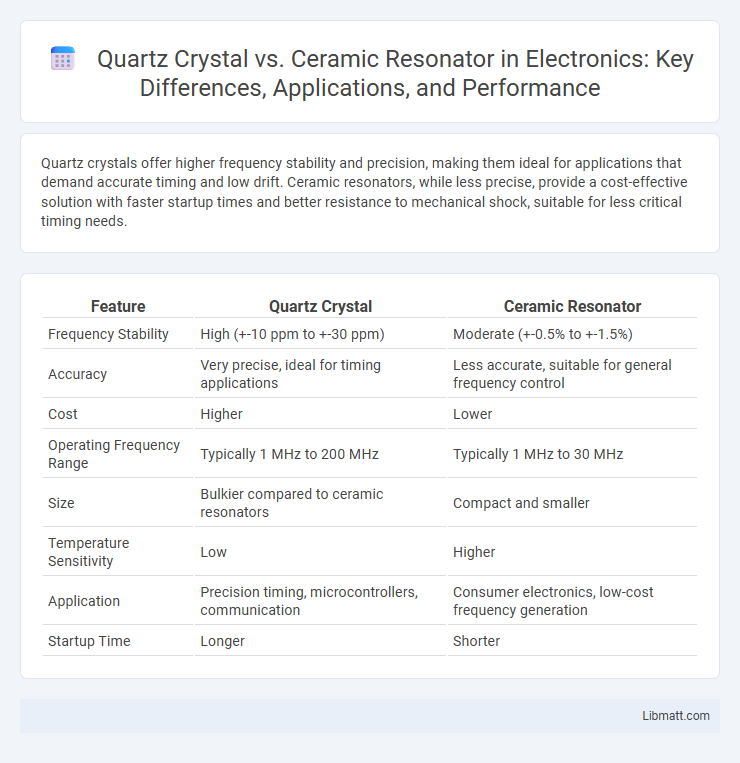

Quartz crystals offer higher frequency stability and precision, making them ideal for applications that demand accurate timing and low drift. Ceramic resonators, while less precise, provide a cost-effective solution with faster startup times and better resistance to mechanical shock, suitable for less critical timing needs.

Table of Comparison

| Feature | Quartz Crystal | Ceramic Resonator |

|---|---|---|

| Frequency Stability | High (+-10 ppm to +-30 ppm) | Moderate (+-0.5% to +-1.5%) |

| Accuracy | Very precise, ideal for timing applications | Less accurate, suitable for general frequency control |

| Cost | Higher | Lower |

| Operating Frequency Range | Typically 1 MHz to 200 MHz | Typically 1 MHz to 30 MHz |

| Size | Bulkier compared to ceramic resonators | Compact and smaller |

| Temperature Sensitivity | Low | Higher |

| Application | Precision timing, microcontrollers, communication | Consumer electronics, low-cost frequency generation |

| Startup Time | Longer | Shorter |

Introduction to Frequency Control Devices

Quartz crystals provide highly stable and precise frequency control due to their piezoelectric properties, making them ideal for applications requiring accurate timing such as watches and communication devices. Ceramic resonators, although less precise, offer cost-effective solutions with faster start-up times and greater resistance to mechanical shock, commonly used in microcontrollers and consumer electronics. Both devices serve essential roles in generating consistent oscillating signals, critical for the functionality of digital circuits and frequency synthesis.

What is a Quartz Crystal Oscillator?

A Quartz Crystal Oscillator is an electronic device that uses the mechanical resonance of a quartz crystal to generate a precise and stable frequency signal, essential for timing applications in clocks, radios, and microcontrollers. Quartz crystals offer high frequency stability, low aging rate, and superior performance compared to ceramic resonators, which are more cost-effective but less accurate. These oscillators provide consistent oscillation frequency due to the piezoelectric properties of quartz, making them ideal for applications requiring precise and reliable timing.

Understanding Ceramic Resonators

Ceramic resonators offer a cost-effective alternative to quartz crystals, providing good frequency stability for less critical timing applications. Unlike quartz crystals that use piezoelectric quartz, ceramic resonators rely on piezoelectric ceramic materials, resulting in lower precision but faster start-up times. Your choice between these two depends on the required accuracy and cost constraints of your electronic circuit design.

Key Differences: Quartz vs. Ceramic

Quartz crystal resonators exhibit superior frequency stability and accuracy due to their piezoelectric properties, making them ideal for precise timing applications. Ceramic resonators offer lower cost and smaller size but have higher frequency tolerance and greater temperature sensitivity, limiting their use to less critical timing functions. The choice between quartz and ceramic depends on the required precision, cost constraints, and environmental conditions of the electronic circuit.

Frequency Accuracy and Stability

Quartz crystals provide superior frequency accuracy and long-term stability, typically within +-10 ppm, making them ideal for precise timing applications. Ceramic resonators generally exhibit lower frequency accuracy, around +-0.5% to +-0.1%, with more significant drift due to temperature changes and aging. The inherent piezoelectric properties of quartz enable consistent oscillation frequency, while ceramic resonators rely on less stable dielectric materials, resulting in reduced frequency performance.

Temperature Effects on Performance

Quartz crystals exhibit superior temperature stability due to their precise piezoelectric characteristics, maintaining consistent frequency over a wide temperature range of approximately -40degC to 85degC. Ceramic resonators, made from barium titanate or related compounds, demonstrate higher sensitivity to temperature variations, causing frequency shifts more pronounced in environments beyond 25degC to 70degC. This makes quartz crystals the preferred choice for applications requiring high frequency accuracy and minimal temperature-induced drift.

Applications: Where Each Excels

Quartz crystals excel in applications requiring high frequency stability and precision, such as wristwatches, communication devices, and microcontrollers. Ceramic resonators are ideal for cost-sensitive consumer electronics and automotive systems, where moderate frequency accuracy is sufficient. Your choice depends on the balance between budget constraints and the need for frequency stability in your specific device.

Size, Cost, and Manufacturing Considerations

Quartz crystals typically offer superior frequency stability and precision but are larger and more expensive than ceramic resonators, which are compact and cost-effective for mass production. Manufacturing quartz crystals requires meticulous processes like cutting and tuning, contributing to higher costs, while ceramic resonators benefit from simpler and faster fabrication techniques. You should consider ceramic resonators for budget-sensitive applications needing moderate accuracy, whereas quartz crystals are preferred where tight frequency control is critical.

Longevity and Reliability Comparison

Quartz crystals offer superior longevity and reliability compared to ceramic resonators due to their stable oscillation frequency and resistance to environmental factors such as temperature and humidity. Quartz crystals typically maintain precision over millions of hours of operation, while ceramic resonators may experience frequency drift and degradation over time. This makes quartz crystals the preferred choice for applications demanding high stability and long-term performance.

How to Choose: Quartz Crystal or Ceramic Resonator?

Choosing between a quartz crystal and a ceramic resonator depends on the required frequency stability and cost considerations. Quartz crystals offer superior frequency accuracy, low temperature drift, and high Q factor, making them ideal for precision timing applications such as microcontrollers and communication devices. Ceramic resonators provide lower cost, smaller size, and acceptable stability for less demanding applications like consumer electronics and basic timing circuits.

Quartz crystal vs Ceramic resonator Infographic

libmatt.com

libmatt.com