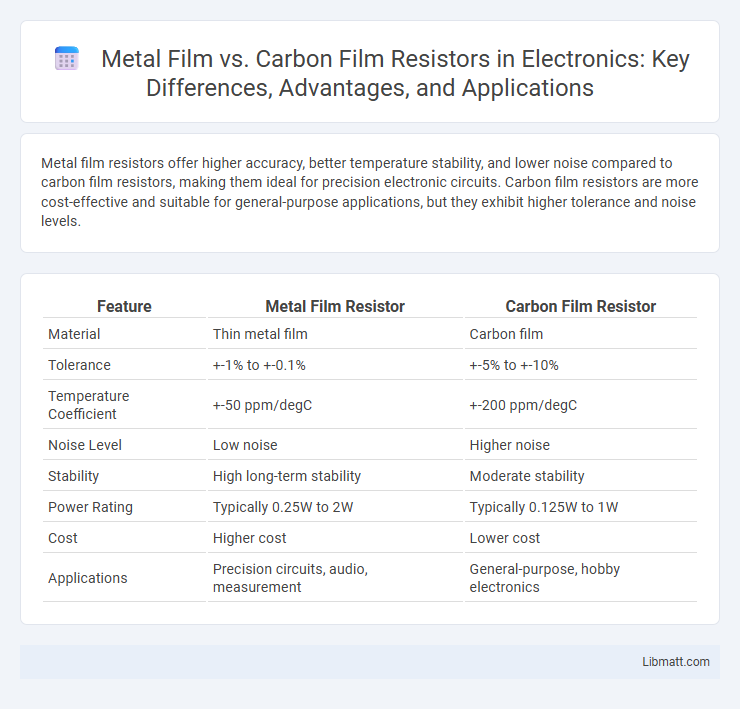

Metal film resistors offer higher accuracy, better temperature stability, and lower noise compared to carbon film resistors, making them ideal for precision electronic circuits. Carbon film resistors are more cost-effective and suitable for general-purpose applications, but they exhibit higher tolerance and noise levels.

Table of Comparison

| Feature | Metal Film Resistor | Carbon Film Resistor |

|---|---|---|

| Material | Thin metal film | Carbon film |

| Tolerance | +-1% to +-0.1% | +-5% to +-10% |

| Temperature Coefficient | +-50 ppm/degC | +-200 ppm/degC |

| Noise Level | Low noise | Higher noise |

| Stability | High long-term stability | Moderate stability |

| Power Rating | Typically 0.25W to 2W | Typically 0.125W to 1W |

| Cost | Higher cost | Lower cost |

| Applications | Precision circuits, audio, measurement | General-purpose, hobby electronics |

Introduction to Metal Film and Carbon Film Resistors

Metal film resistors feature a thin metal layer deposited on a ceramic substrate, offering superior precision, stability, and low noise compared to carbon film resistors, which use a carbon-based composition. Carbon film resistors are commonly chosen for cost-effective, general-purpose applications but exhibit higher tolerance and noise levels. Your choice between metal film and carbon film resistors impacts circuit accuracy, reliability, and overall performance based on specific electronic requirements.

Construction and Material Differences

Metal film resistors use a thin layer of metal alloy, typically nickel-chromium, deposited on a ceramic core, offering higher precision and stability. Carbon film resistors consist of a carbon-based layer applied to a ceramic substrate, resulting in lower cost but greater variability in resistance and noise. Choosing between them impacts the accuracy and durability of Your electronic circuits, with metal film favored for high-performance applications.

Electrical Properties Comparison

Metal film resistors exhibit lower noise levels and tighter tolerance ranges, typically +-1% or better, compared to carbon film resistors which usually have tolerances around +-5%. Metal film resistors maintain higher stability and temperature coefficients, often below 50 ppm/degC, while carbon film types can reach up to 200 ppm/degC, impacting precision in sensitive circuits. The superior electrical properties of metal film resistors make them ideal for applications demanding accurate and stable resistance values.

Tolerance and Precision Levels

Metal film resistors typically offer tighter tolerance levels, often within +-1% or lower, compared to carbon film resistors which commonly have tolerances around +-5%. The precision of metal film resistors makes them ideal for applications requiring stable and accurate resistance values under varying environmental conditions. Carbon film resistors, while more cost-effective, exhibit greater resistance variability and less precision, limiting their use in high-accuracy circuits.

Temperature Coefficient and Stability

Metal film resistors offer superior temperature coefficient values, typically around +-50 ppm/degC, ensuring more consistent resistance with temperature fluctuations compared to carbon film resistors, which can exhibit coefficients as high as +-200 ppm/degC. This low temperature coefficient in metal film resistors translates to enhanced long-term stability and reliability, making them ideal for precision circuits requiring minimal drift over time. When selecting components for your design, metal film resistors provide better stability under varying thermal conditions, improving overall performance and accuracy.

Noise Performance Analysis

Metal film resistors exhibit significantly lower noise levels compared to carbon film resistors due to their precise manufacturing process and homogeneous structure, resulting in minimal excess noise and superior stability under varying electrical conditions. Carbon film resistors tend to generate more noise because of the granular composition of the carbon film, leading to increased microphonic effects and excess noise, especially in high-frequency applications. When optimizing your circuit for noise-sensitive environments, metal film resistors ensure enhanced signal integrity and reliable performance.

Power Rating and Size Considerations

Metal film resistors typically offer higher power ratings ranging from 0.25W to 2W, enabling them to handle greater energy dissipation in compact sizes compared to carbon film resistors, which generally max out around 0.5W to 1W. The size of a metal film resistor tends to be smaller for equivalent power ratings, making them ideal for applications requiring space efficiency and thermal stability. You should consider your project's power demands and available PCB space when choosing between metal film and carbon film resistors to ensure optimal performance and reliability.

Common Applications of Metal Film Resistors

Metal film resistors are commonly used in precision electronic circuits, audio equipment, and measuring instruments due to their low noise and high stability. Their applications extend to voltage regulators, amplifiers, and high-frequency devices where tight tolerance and thermal stability are crucial. These resistors are preferred in telecommunications and medical devices for their reliability and consistent performance over time.

Typical Uses of Carbon Film Resistors

Carbon film resistors are commonly used in general-purpose electronic applications due to their cost-effectiveness and moderate tolerance levels. They are suitable for audio equipment, signal processing, and low-power circuits where noise performance is less critical. Your projects involving affordable, stable resistance components often benefit from the versatility and reliability of carbon film resistors.

Choosing the Right Resistor for Your Project

Metal film resistors provide higher precision, lower noise, and better temperature stability compared to carbon film resistors, making them ideal for applications requiring accurate and reliable resistance values. Carbon film resistors are more cost-effective and suitable for general-purpose circuits where tight tolerance is less critical. Your choice should depend on the specific electrical performance needs, with metal film preferred for high-accuracy projects and carbon film for budget-friendly, less sensitive designs.

Metal Film vs Carbon Film Resistor Infographic

libmatt.com

libmatt.com