Varistors and Metal Oxide Varistors (MOVs) both protect electronic circuits from voltage spikes, but MOVs are a specific type of varistor made from metal oxide materials, offering faster response times and better energy absorption. Your choice depends on the application, with MOVs preferred for high-energy surge protection and varistors used in general voltage regulation.

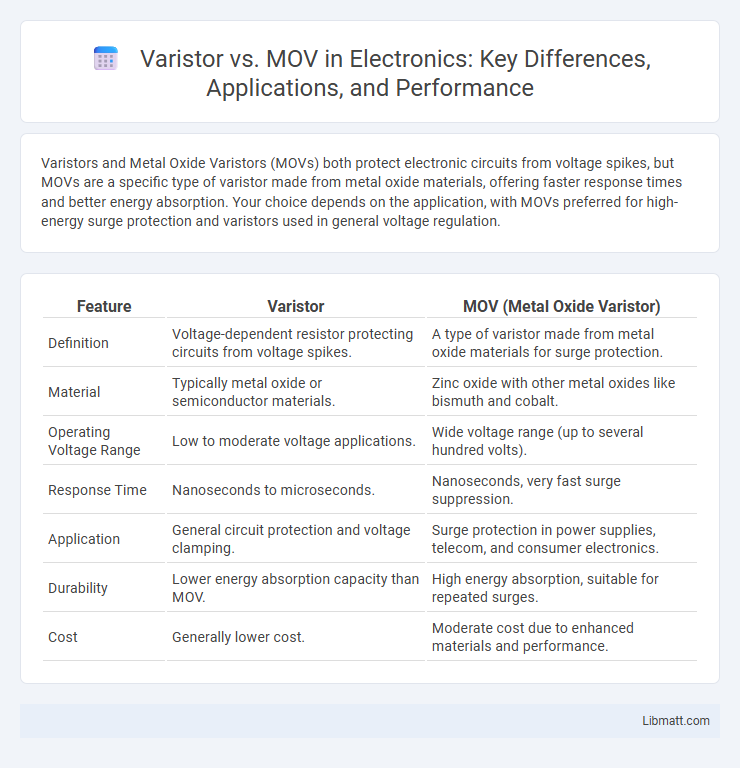

Table of Comparison

| Feature | Varistor | MOV (Metal Oxide Varistor) |

|---|---|---|

| Definition | Voltage-dependent resistor protecting circuits from voltage spikes. | A type of varistor made from metal oxide materials for surge protection. |

| Material | Typically metal oxide or semiconductor materials. | Zinc oxide with other metal oxides like bismuth and cobalt. |

| Operating Voltage Range | Low to moderate voltage applications. | Wide voltage range (up to several hundred volts). |

| Response Time | Nanoseconds to microseconds. | Nanoseconds, very fast surge suppression. |

| Application | General circuit protection and voltage clamping. | Surge protection in power supplies, telecom, and consumer electronics. |

| Durability | Lower energy absorption capacity than MOV. | High energy absorption, suitable for repeated surges. |

| Cost | Generally lower cost. | Moderate cost due to enhanced materials and performance. |

Introduction to Varistors and MOVs

Varistors and Metal Oxide Varistors (MOVs) are essential components used for voltage surge protection in electronic circuits. Varistors are nonlinear resistors that change resistance with voltage, while MOVs, a specific type of varistor made from metal oxide materials, provide enhanced energy absorption and durability. Understanding the difference helps you select the appropriate device for safeguarding sensitive electronic equipment from transient voltage spikes.

What is a Varistor?

A varistor is a voltage-dependent resistor designed to protect electronic circuits from excessive voltage by changing its resistance with voltage fluctuations, effectively clamping transient surges. Metal Oxide Varistors (MOVs) are the most common type, composed of zinc oxide grains that create a nonlinear current-voltage characteristic, enabling rapid response to voltage spikes. Understanding how a varistor functions can help you safeguard your electronic devices from damaging voltage surges.

Understanding Metal Oxide Varistors (MOVs)

Metal Oxide Varistors (MOVs) protect electronic circuits by clamping high voltage surges and diverting excess current away from sensitive components. Unlike traditional varistors, MOVs use a ceramic composition of zinc oxide grains to achieve nonlinear resistance, ensuring efficient energy absorption during transient voltage spikes. Your devices benefit from MOVs' fast response time and high energy dissipation capabilities, making them essential for surge protection in power supplies and communication lines.

Structural Differences: Varistor vs MOV

Varistors and MOVs both protect circuits from voltage spikes but differ structurally; a varistor typically uses zinc oxide grains pressed into a ceramic matrix, forming multiple grain-boundary junctions that control current flow. Metal Oxide Varistors (MOVs), a type of varistor, specifically consist of zinc oxide powder mixed with other metal oxides, sintered into a ceramic disc with electrode layers on each side, enhancing energy absorption. Understanding the structural differences in your protective component choice can optimize circuit reliability and transient voltage suppression performance.

Electrical Characteristics Comparison

Varistors and Metal Oxide Varistors (MOVs) are both nonlinear resistors used for voltage clamping and surge protection, but MOVs typically feature faster response times and higher energy absorption capabilities. The electrical characteristics of MOVs include a wide voltage range from a few volts to several kilovolts and a nonlinear voltage-current curve with a steep clamping region, whereas traditional varistors often exhibit slower response and lower surge current ratings. MOVs also offer improved thermal stability and lower capacitance, making them more suitable for high-frequency applications compared to general varistors.

Applications of Varistors and MOVs

Varistors and Metal Oxide Varistors (MOVs) are widely used in surge protection applications to safeguard electronic circuits from voltage spikes and transient surges. Varistors are commonly found in power strips, voltage stabilizers, and household appliances to absorb excess voltage and prevent damage. MOVs are preferred in industrial equipment, telecommunication systems, and power distribution networks due to their high energy absorption capacity and fast response time.

Advantages and Limitations

Varistors, particularly Metal Oxide Varistors (MOVs), offer excellent surge protection by clamping voltage spikes and diverting excess current, making them effective for safeguarding electronic circuits from transient voltage events. MOVs exhibit fast response times and high energy absorption capacity but can degrade over time with repeated surges, leading to reduced protection and eventual failure. Understanding the balance between MOV durability and protection level helps you select the appropriate component for your specific voltage regulation needs.

Reliability and Lifespan

Varistors and MOVs (Metal Oxide Varistors) both protect circuits from voltage spikes, but MOVs generally offer higher reliability due to their consistent clamping voltage and robust energy absorption capabilities. The lifespan of MOVs varies based on exposure to transient voltage events, with degradation occurring after repeated surges, whereas varistors tend to have a shorter effective lifespan under similar conditions. Proper MOV selection and usage can significantly enhance circuit protection longevity compared to standard varistors.

Selection Criteria for Circuit Protection

Selection criteria for circuit protection between varistors and MOVs hinge on their voltage clamping abilities and energy absorption capacity. Varistors provide nonlinear resistance changes at specified voltage thresholds, making them ideal for transient voltage suppression in sensitive electronics, while MOVs offer robust energy dissipation for high-energy surges and lightning protection. Evaluating your circuit's maximum operating voltage, expected surge currents, and response time will guide the optimal choice for reliable and efficient protection.

Varistor vs MOV: Which Should You Choose?

Varistor and MOV (Metal Oxide Varistor) both protect electronic circuits from voltage spikes by clamping excess voltage, but MOVs offer faster response times and higher energy absorption capacity, making them ideal for sensitive devices. Varistors, typically zinc oxide-based like MOVs, are cost-effective and commonly used for general surge protection in household and industrial applications. Choosing between Varistor and MOV depends on the specific voltage surge characteristics, required durability, and application sensitivity to ensure optimal circuit protection.

Varistor vs MOV Infographic

libmatt.com

libmatt.com