Metal Oxide Varistors (MOVs) protect your electronic circuits by clamping high voltage surges with fast response times and energy absorption, making them ideal for transient voltage suppression. Gas Discharge Tubes (GDTs) handle larger surge currents by ionizing and creating a low-resistance path during high voltage spikes, offering robust protection in power distribution and telecom systems.

Table of Comparison

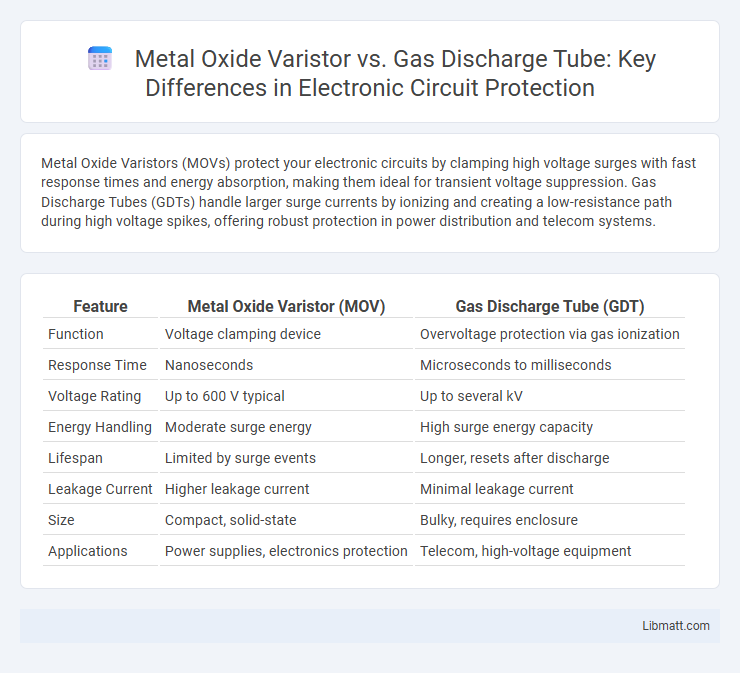

| Feature | Metal Oxide Varistor (MOV) | Gas Discharge Tube (GDT) |

|---|---|---|

| Function | Voltage clamping device | Overvoltage protection via gas ionization |

| Response Time | Nanoseconds | Microseconds to milliseconds |

| Voltage Rating | Up to 600 V typical | Up to several kV |

| Energy Handling | Moderate surge energy | High surge energy capacity |

| Lifespan | Limited by surge events | Longer, resets after discharge |

| Leakage Current | Higher leakage current | Minimal leakage current |

| Size | Compact, solid-state | Bulky, requires enclosure |

| Applications | Power supplies, electronics protection | Telecom, high-voltage equipment |

Introduction: Metal Oxide Varistor vs Gas Discharge Tube

Metal Oxide Varistors (MOVs) provide fast, nonlinear voltage clamping ideal for transient voltage suppression in sensitive electronic circuits. Gas Discharge Tubes (GDTs) offer high-energy surge protection by ionizing gas within the tube to shunt large currents during power spikes. For your protection needs, MOVs excel in low-energy, rapid response, while GDTs handle higher energy surges with longer response times.

Working Principle of Metal Oxide Varistors

Metal Oxide Varistors (MOVs) operate by exploiting the nonlinear voltage-current characteristics of zinc oxide grains, which form numerous grain boundaries acting as barrier layers. When a transient voltage surge occurs, the MOV rapidly decreases its resistance, allowing current to flow and clamping the voltage to a safe level, thereby protecting electronic circuits from damage. Unlike Gas Discharge Tubes (GDTs) that rely on gas ionization to conduct surge currents, MOVs respond instantaneously through solid-state conduction without arc formation.

How Gas Discharge Tubes Operate

Gas Discharge Tubes (GDTs) protect electronic circuits by using an inert gas that ionizes under high voltage, creating a conductive plasma to divert surges away from sensitive components. When voltage exceeds a specific threshold, the gas inside the tube becomes conductive, sharply reducing resistance and allowing excess current to safely ground. Your equipment benefits from this fast-acting, high-energy surge protection, especially in telecommunication and power distribution systems where transient voltage spikes are common.

Key Differences Between MOVs and GDTs

Metal Oxide Varistors (MOVs) and Gas Discharge Tubes (GDTs) differ primarily in their response times and voltage clamping capabilities; MOVs react within nanoseconds to transient voltage spikes, making them suitable for rapid voltage suppression, while GDTs have slower response times but can handle higher surge currents and provide better protection against sustained overvoltages. MOVs degrade gradually with repeated surges, leading to a reduction in clamping efficiency, whereas GDTs maintain their performance over many surges due to their robust gas discharge mechanism. The choice between MOVs and GDTs depends on application-specific requirements for energy absorption, response speed, durability, and voltage protection levels in power and signal line circuit designs.

Surge Protection Capabilities Compared

Metal Oxide Varistors (MOVs) offer superior surge protection capabilities for high-frequency transient voltage spikes with rapid response times and clamping voltages typically between 10V to 1,000V. Gas Discharge Tubes (GDTs) excel in handling high-energy surges by diverting large current flows, but they have slower response times and higher voltage thresholds, usually above 90V. MOVs are optimal for sensitive electronics requiring fast voltage suppression, while GDTs are preferred in industrial applications demanding robust protection against extreme surge events and lightning strikes.

Response Time and Performance Under Transients

Metal Oxide Varistors (MOVs) exhibit response times in the nanosecond range, enabling rapid suppression of transient voltage spikes, while Gas Discharge Tubes (GDTs) typically respond in microseconds, which is slower but can handle higher energy surges. MOVs perform efficiently in clamping voltage surges with low residual voltage, making them ideal for fast transient voltage suppression; GDTs excel in handling high-current surges with superior energy absorption capacity but may allow higher let-through voltage. The differing response times and energy handling capabilities define their complementary roles in transient voltage protection systems, with MOVs preferred for fast, low-energy transients and GDTs suited for high-energy, slower events.

Applications and Use Cases for MOVs

Metal Oxide Varistors (MOVs) are widely used in electronic devices and power strips to protect against voltage surges caused by lightning strikes, switching operations, and electrostatic discharge. Their fast response time and ability to absorb high-energy transients make them ideal for safeguarding consumer electronics, industrial equipment, and telecommunications systems. Your choice of MOVs ensures reliable surge protection in applications requiring compact, cost-effective solutions.

Typical Applications for GDTs

Gas Discharge Tubes (GDTs) are commonly used in telecommunications, power distribution, and industrial equipment to protect sensitive electronics from high-energy surges caused by lightning strikes or electrical faults. Their ability to handle high surge currents and voltage spikes makes them ideal for safeguarding telephone lines, coaxial cables, and power supply circuits. You can rely on GDTs for cost-effective, high-capacity transient voltage suppression in harsh electrical environments.

Advantages and Limitations of MOVs vs GDTs

Metal Oxide Varistors (MOVs) offer rapid response times and high energy absorption capacity, making them ideal for protecting sensitive electronic equipment from transient voltage spikes. Gas Discharge Tubes (GDTs) provide excellent high-voltage tolerance and long service life but have slower response times compared to MOVs. While MOVs can degrade over time due to repeated surges, GDTs maintain consistent performance yet may require higher voltage to trigger conduction.

Choosing the Right Surge Protection Device

Metal Oxide Varistors (MOVs) offer fast response times and are ideal for clamping transient voltage spikes in household electronics, while Gas Discharge Tubes (GDTs) excel at handling high-energy surges in industrial applications due to their higher current capacity. Selecting the right surge protection device depends on factors such as the operating voltage, expected surge magnitude, and response time requirements. Combining MOVs and GDTs in coordinated protection circuits often results in optimal surge mitigation by leveraging the strengths of both components.

Metal Oxide Varistor vs Gas Discharge Tube Infographic

libmatt.com

libmatt.com