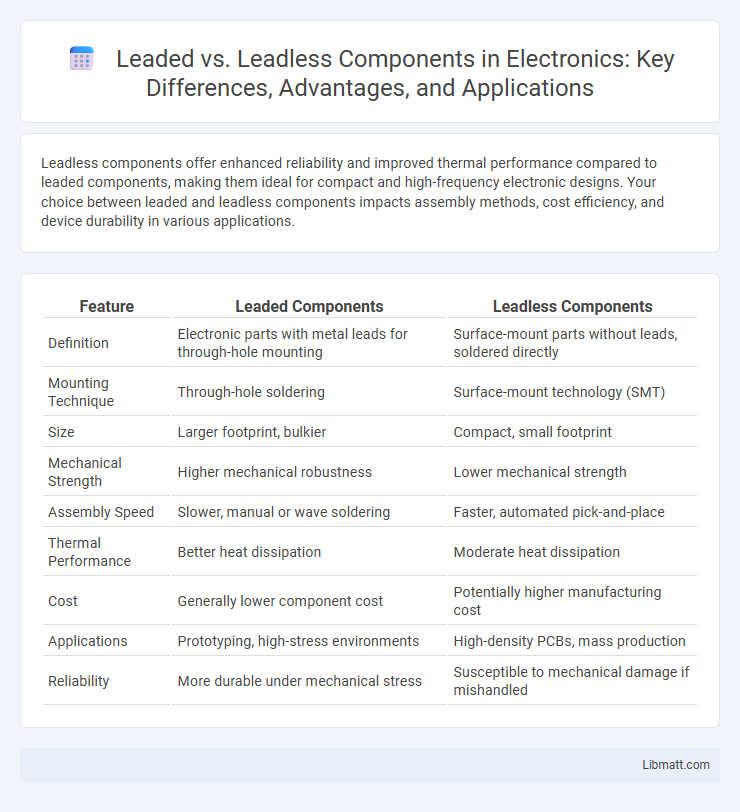

Leadless components offer enhanced reliability and improved thermal performance compared to leaded components, making them ideal for compact and high-frequency electronic designs. Your choice between leaded and leadless components impacts assembly methods, cost efficiency, and device durability in various applications.

Table of Comparison

| Feature | Leaded Components | Leadless Components |

|---|---|---|

| Definition | Electronic parts with metal leads for through-hole mounting | Surface-mount parts without leads, soldered directly |

| Mounting Technique | Through-hole soldering | Surface-mount technology (SMT) |

| Size | Larger footprint, bulkier | Compact, small footprint |

| Mechanical Strength | Higher mechanical robustness | Lower mechanical strength |

| Assembly Speed | Slower, manual or wave soldering | Faster, automated pick-and-place |

| Thermal Performance | Better heat dissipation | Moderate heat dissipation |

| Cost | Generally lower component cost | Potentially higher manufacturing cost |

| Applications | Prototyping, high-stress environments | High-density PCBs, mass production |

| Reliability | More durable under mechanical stress | Susceptible to mechanical damage if mishandled |

Introduction to Leaded and Leadless Components

Leaded components feature wire leads for through-hole mounting on printed circuit boards (PCBs), offering reliable mechanical strength and ease of manual assembly. Leadless components, such as chip resistors and capacitors, rely on surface-mount technology (SMT) for direct soldering onto PCB pads, enabling higher component density and automated production. The choice between leaded and leadless components impacts design complexity, manufacturing efficiency, and overall device size.

Key Differences Between Leaded and Leadless Components

Leaded components feature protruding metal leads for through-hole mounting, offering easier manual assembly and stronger mechanical bonds on circuit boards. Leadless components, such as chip resistors and capacitors, rely on surface-mount technology with no leads, enabling higher component density and improved electrical performance on compact PCBs. The key differences encompass assembly method, size, mechanical stability, and suitability for automated manufacturing in modern electronic devices.

Advantages of Leaded Components

Leaded components offer superior mechanical stability due to their through-hole mounting, making them ideal for applications requiring strong physical connections. Their ease of manual handling and soldering enhances repairability and prototyping efficiency, especially in low-volume production. You benefit from better heat dissipation and reliable electrical performance in high-stress environments when using leaded components.

Advantages of Leadless Components

Leadless components offer superior thermal performance due to their direct PCB contact, enabling efficient heat dissipation that enhances device reliability. Their compact design supports higher circuit density and miniaturization, crucial for modern electronics requiring smaller, lighter devices. Moreover, leadless components reduce environmental impact by eliminating hazardous lead materials, aligning with RoHS compliance and sustainability goals.

Disadvantages of Leaded Components

Leaded components present several disadvantages, including higher susceptibility to mechanical stress and limited compatibility with automated assembly processes, resulting in increased manufacturing time and costs. Their larger footprint on printed circuit boards (PCBs) restricts design density and can lead to inefficient use of space in modern compact electronic devices. You may also encounter environmental concerns due to the use of hazardous lead materials, which require special handling and disposal procedures.

Disadvantages of Leadless Components

Leadless components often face challenges in heat dissipation due to the absence of leads that typically aid in thermal conduction, which can lead to premature device failure. Their smaller soldering pads make inspection and rework more difficult, increasing assembly complexity and potential for defects. Limited mechanical flexibility in leadless components can result in higher susceptibility to stress and cracking during vibration or thermal cycling.

Assembly Methods: Leaded vs Leadless

Leaded components are assembled using through-hole technology, where component leads are inserted into drilled holes on the PCB and soldered on the opposite side, providing strong mechanical bonds ideal for high-stress environments. Leadless components, such as chip resistors and capacitors, use surface-mount technology (SMT), allowing for direct soldering onto PCB pads, enabling higher component density and faster automated assembly. SMT improves production speed and reduces board size but requires precise placement and reflow soldering profiles to ensure reliability.

Reliability and Performance Comparison

Leaded components typically offer stronger mechanical connections due to their through-hole mounting, enhancing reliability in high-vibration environments, whereas leadless components provide superior electrical performance with lower inductance and capacitance, benefiting high-frequency applications. Leadless designs improve thermal management through better heat dissipation, while leaded parts excel in durability and ease of inspection during manufacturing. Your choice between leaded and leadless components should consider the balance between mechanical robustness and electrical performance demands.

Common Applications of Leaded and Leadless Components

Leaded components are predominantly used in through-hole technology applications such as power supplies, automotive electronics, and industrial equipment where mechanical strength and ease of manual soldering are essential. Leadless components, often found in surface-mount technology (SMT), dominate consumer electronics, smartphones, and compact medical devices due to their smaller footprint and suitability for high-density circuit boards. The choice between leaded and leadless components significantly impacts assembly methods, thermal performance, and overall device miniaturization.

Choosing the Right Component for Your Project

Selecting the appropriate component type significantly impacts the efficiency and durability of your electronic project. Leaded components offer easy manual soldering and are ideal for prototyping and low-volume production, while leadless components provide compact size and enhanced performance for high-density, automated assembly. Consider factors such as assembly method, space constraints, and thermal requirements to determine the optimal choice for your specific project needs.

Leaded vs Leadless Component Infographic

libmatt.com

libmatt.com