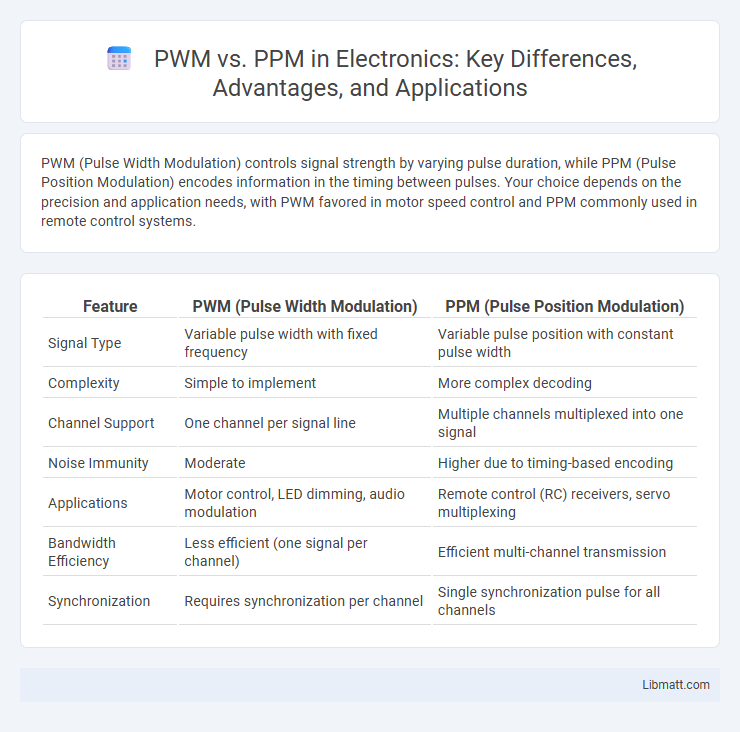

PWM (Pulse Width Modulation) controls signal strength by varying pulse duration, while PPM (Pulse Position Modulation) encodes information in the timing between pulses. Your choice depends on the precision and application needs, with PWM favored in motor speed control and PPM commonly used in remote control systems.

Table of Comparison

| Feature | PWM (Pulse Width Modulation) | PPM (Pulse Position Modulation) |

|---|---|---|

| Signal Type | Variable pulse width with fixed frequency | Variable pulse position with constant pulse width |

| Complexity | Simple to implement | More complex decoding |

| Channel Support | One channel per signal line | Multiple channels multiplexed into one signal |

| Noise Immunity | Moderate | Higher due to timing-based encoding |

| Applications | Motor control, LED dimming, audio modulation | Remote control (RC) receivers, servo multiplexing |

| Bandwidth Efficiency | Less efficient (one signal per channel) | Efficient multi-channel transmission |

| Synchronization | Requires synchronization per channel | Single synchronization pulse for all channels |

Introduction to PWM and PPM

Pulse Width Modulation (PWM) controls power delivery by varying the width of voltage pulses, enabling precise regulation of motor speed, LED brightness, and other electronic applications. Pulse Position Modulation (PPM) encodes information by shifting the position of a pulse within a fixed time frame, commonly used in radio control systems to transmit multiple channels efficiently. Choosing between PWM and PPM depends on your need for either fine-grained power control or multi-channel signal transmission.

Defining Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) is a technique used to control the amount of power delivered to electronic devices by varying the width of the pulses in a signal while maintaining a constant frequency. PWM signals switch between on and off states rapidly, with the duration of the "on" time determining the effective voltage and power output. You can optimize motor speed, LED brightness, and servo positioning by adjusting PWM duty cycles for precise control.

Understanding Pulse Position Modulation (PPM)

Pulse Position Modulation (PPM) encodes information by varying the position of a pulse within a fixed time frame, making it distinct from Pulse Width Modulation (PWM), which varies the pulse duration. PPM signals are less susceptible to signal degradation and interference because the information is contained in the timing rather than the pulse width. This characteristic makes PPM a preferred choice in radio control systems and communication protocols requiring precise timing and reduced latency.

Key Differences Between PWM and PPM

PWM (Pulse Width Modulation) controls device output by varying the width of voltage pulses, while PPM (Pulse Position Modulation) encodes information through the timing or position of each pulse within a signal frame. PWM offers precise control over power delivery and speed, making it ideal for motor control and LED dimming, whereas PPM excels in radio control systems by transmitting multiple channels in a single signal based on pulse timing. Understanding these key differences helps you select the appropriate modulation technique for efficient signal processing and communication.

Signal Generation and Transmission

PWM (Pulse Width Modulation) generates signals by varying the width of fixed-frequency pulses to represent information, while PPM (Pulse Position Modulation) encodes data by shifting the position of pulses within a fixed time frame. PWM signals maintain a constant pulse interval with amplitude changes, enabling simpler receiver decoding, whereas PPM involves precise timing measurement between pulses, requiring more complex synchronization. Your choice between PWM and PPM impacts signal robustness and susceptibility to noise, influencing the efficiency of transmission in applications like remote control systems.

Applications of PWM in Modern Technology

PWM (Pulse Width Modulation) is widely used in modern technology for controlling motor speed, dimming LEDs, and managing power delivery in renewable energy systems. Its precision in adjusting the duty cycle allows for efficient energy use and reduces heat generation in electronic devices. You can find PWM applications in robotics, automotive systems, and consumer electronics, where accurate signal modulation is critical.

Common Uses of PPM in Communication Systems

PPM (Pulse Position Modulation) is widely used in communication systems for encoding information through varying pulse timing, offering high noise immunity and efficient bandwidth utilization. Common applications include remote control systems for drones and model aircraft, where precise signal timing is crucial for controlling servos. PPM also finds use in optical communication and time-sensitive data transmission, making it ideal for environments requiring synchronized pulse coordination.

Advantages and Disadvantages of PWM

Pulse Width Modulation (PWM) offers precise control of power delivery by varying the duty cycle of a fixed frequency signal, making it highly efficient for motor speed and LED brightness control. Its advantages include simple implementation, low electromagnetic interference, and high-resolution control in digital systems. However, PWM can generate audible noise in motors and may require additional filtering to smooth output signals in sensitive analog applications.

Pros and Cons of PPM

PPM (Pulse Position Modulation) offers improved noise immunity and better signal integrity compared to PWM (Pulse Width Modulation), making it ideal for applications requiring precise control, like RC systems and communication devices. However, PPM's complexity in decoding and synchronization can lead to increased processing requirements and potential latency issues in real-time systems. Your choice of modulation should consider PPM's advantages in reducing signal interference alongside its challenges in implementation and timing accuracy.

Choosing Between PWM and PPM: Which Is Best?

Choosing between PWM (Pulse Width Modulation) and PPM (Pulse Position Modulation) depends on your specific application requirements, such as signal complexity and noise tolerance. PWM offers precise control over individual channels and is ideal for applications requiring high accuracy in speed or position control. PPM simplifies wiring by combining multiple channels into a single signal, making it suitable for remote control systems where reducing interference is critical.

PWM vs PPM Infographic

libmatt.com

libmatt.com