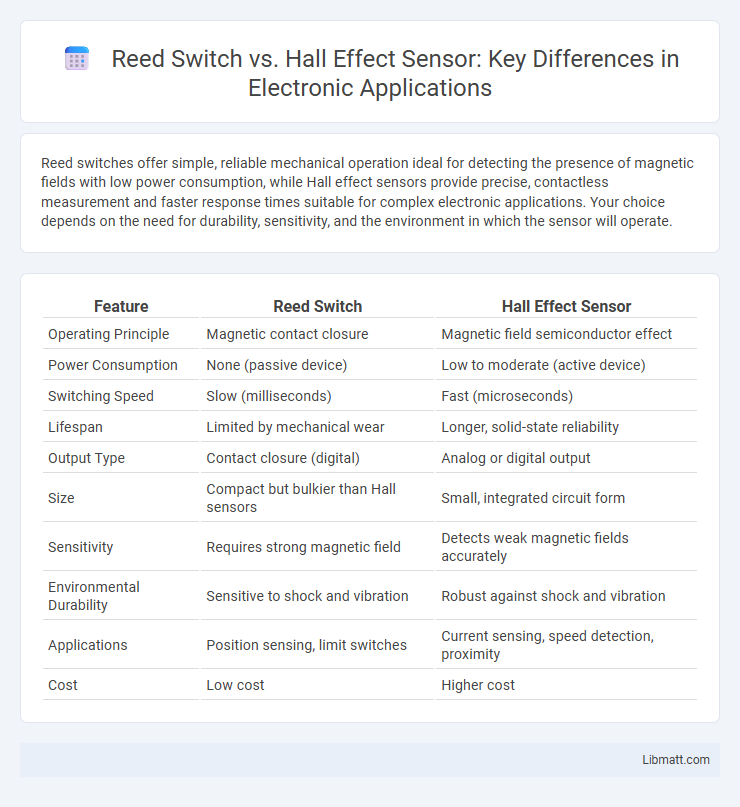

Reed switches offer simple, reliable mechanical operation ideal for detecting the presence of magnetic fields with low power consumption, while Hall effect sensors provide precise, contactless measurement and faster response times suitable for complex electronic applications. Your choice depends on the need for durability, sensitivity, and the environment in which the sensor will operate.

Table of Comparison

| Feature | Reed Switch | Hall Effect Sensor |

|---|---|---|

| Operating Principle | Magnetic contact closure | Magnetic field semiconductor effect |

| Power Consumption | None (passive device) | Low to moderate (active device) |

| Switching Speed | Slow (milliseconds) | Fast (microseconds) |

| Lifespan | Limited by mechanical wear | Longer, solid-state reliability |

| Output Type | Contact closure (digital) | Analog or digital output |

| Size | Compact but bulkier than Hall sensors | Small, integrated circuit form |

| Sensitivity | Requires strong magnetic field | Detects weak magnetic fields accurately |

| Environmental Durability | Sensitive to shock and vibration | Robust against shock and vibration |

| Applications | Position sensing, limit switches | Current sensing, speed detection, proximity |

| Cost | Low cost | Higher cost |

Introduction to Reed Switches and Hall Effect Sensors

Reed switches are electromagnetic components consisting of two ferromagnetic blades sealed in a glass envelope that close or open in the presence of a magnetic field, providing reliable, low-power switching for various applications. Hall effect sensors operate by detecting changes in magnetic fields through the Hall effect principle, allowing for precise, contactless measurement of magnetic flux density with high sensitivity and durability. Both devices serve critical roles in magnetic sensing and switching but differ fundamentally in their operating mechanisms and application suitability.

How Reed Switches Work

Reed switches operate by using two ferromagnetic blades sealed within a glass capsule that close or open an electrical circuit in response to an external magnetic field. When a magnet approaches the switch, the blades are drawn together by magnetic attraction, completing the circuit without physical contact. This simple mechanical action offers reliable, low-power switching ideal for position sensing and security applications.

How Hall Effect Sensors Operate

Hall Effect sensors operate by detecting changes in magnetic fields through the Hall voltage generated across a conductive material when exposed to a magnetic flux. Unlike reed switches that rely on the physical movement of ferromagnetic contacts, Hall Effect sensors offer precise, non-contact measurement and faster response times. Your applications benefit from their durability, allowing for seamless integration in harsh environments and ensuring reliable, maintenance-free operation.

Key Differences Between Reed Switches and Hall Effect Sensors

Reed switches operate as magnetic contact sensors that open or close circuits when exposed to a magnetic field, relying on mechanical reeds encased in a glass tube. Hall effect sensors use semiconductor technology to detect magnetic fields by producing a voltage proportional to the magnetic flux density, enabling contactless and continuous sensing. Unlike reed switches, Hall effect sensors offer higher durability, faster response times, and can measure varying magnetic intensities, making them ideal for applications requiring precision and reliability.

Sensitivity and Accuracy Comparison

Reed switches offer high sensitivity to magnetic fields but are limited by mechanical wear and slower response times, impacting their accuracy in dynamic environments. Hall effect sensors provide superior accuracy and consistency with faster response rates due to their solid-state design, making them ideal for precise position and speed sensing. Your choice depends on the application's sensitivity requirements and the need for long-term reliable performance.

Durability and Lifespan Considerations

Reed switches offer reliable durability with a typical lifespan of around 10 million operations due to their mechanical contacts, but they are susceptible to wear and environmental stress. Hall effect sensors, being solid-state devices, provide significantly longer operational life--often exceeding 100 million cycles--without mechanical degradation, making them ideal for applications requiring high durability and low maintenance. Your choice should consider the operating environment and required lifespan, with Hall effect sensors favored for harsh conditions and extended use.

Application Areas: Reed Switch vs Hall Effect Sensor

Reed switches are widely used in security systems, appliance controls, and position sensing due to their simplicity and low cost. Hall effect sensors are preferred in automotive applications, brushless DC motors, and current sensing because of their durability and ability to provide continuous, non-contact measurements. The choice between these sensors depends on factors such as environmental conditions, precision requirements, and response time needs in various industrial and consumer electronics applications.

Cost and Availability Analysis

Reed switches typically offer lower costs due to their simple mechanical design and widespread availability from multiple suppliers, making them an economical choice for basic magnetic sensing applications. Hall effect sensors, while generally more expensive, provide enhanced durability and integration capabilities, often available through specialized electronics distributors with robust supply chains. Your decision should factor in not only initial cost but also long-term availability and application requirements to ensure optimal performance and budget alignment.

Pros and Cons of Reed Switches vs Hall Effect Sensors

Reed switches offer simple, cost-effective solutions with no power consumption when inactive and reliable operation in low-speed applications, but they are prone to mechanical wear, limited switching frequency, and sensitivity to vibration. Hall effect sensors provide non-contact, high-speed, and durable performance with digital output and precise position sensing, yet they typically require power, cost more, and may be influenced by external magnetic fields. You should choose based on your application's need for durability, speed, and power efficiency.

Choosing the Right Sensor for Your Application

Choosing the right sensor between a reed switch and a Hall effect sensor depends on factors like durability, sensitivity, and environmental conditions. Reed switches offer reliable performance in low-power, mechanical environments but are prone to wear and slower response times, while Hall effect sensors provide higher precision, faster response, and longer lifespan due to their solid-state design. Evaluating application requirements such as switching speed, current capacity, and exposure to harsh conditions ensures optimal sensor selection for improved system efficiency.

Reed Switch vs Hall Effect Sensor Infographic

libmatt.com

libmatt.com