QFP (Quad Flat Package) offers easily accessible leads around the package edges, making it suitable for manual soldering and prototyping, while BGA (Ball Grid Array) features solder balls underneath the package, providing better electrical performance and thermal dissipation in high-density applications. Your choice depends on the specific requirements for assembly complexity, reliability, and signal integrity in your electronic design.

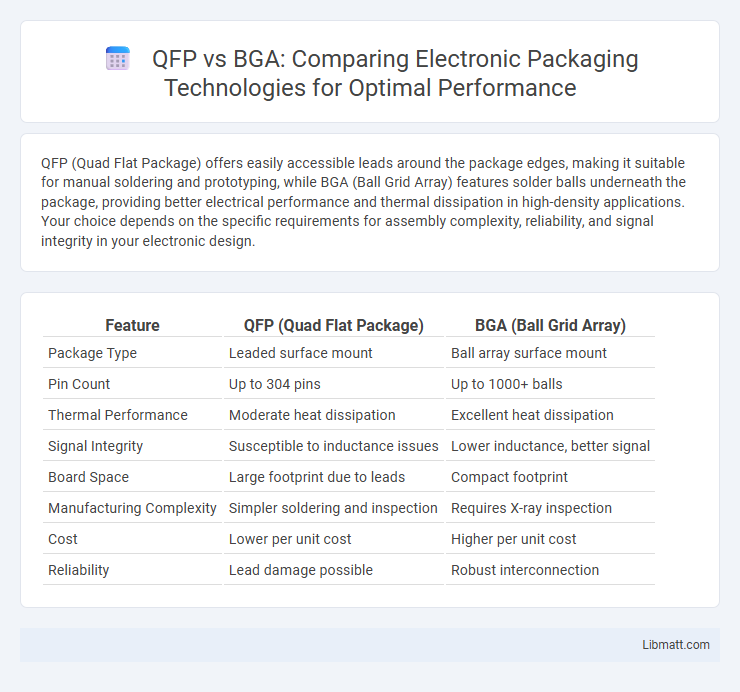

Table of Comparison

| Feature | QFP (Quad Flat Package) | BGA (Ball Grid Array) |

|---|---|---|

| Package Type | Leaded surface mount | Ball array surface mount |

| Pin Count | Up to 304 pins | Up to 1000+ balls |

| Thermal Performance | Moderate heat dissipation | Excellent heat dissipation |

| Signal Integrity | Susceptible to inductance issues | Lower inductance, better signal |

| Board Space | Large footprint due to leads | Compact footprint |

| Manufacturing Complexity | Simpler soldering and inspection | Requires X-ray inspection |

| Cost | Lower per unit cost | Higher per unit cost |

| Reliability | Lead damage possible | Robust interconnection |

Overview of QFP and BGA Packages

QFP (Quad Flat Package) features a flat, rectangular design with leads extending from all four sides, making it ideal for surface mounting on PCBs with moderate pin counts. BGA (Ball Grid Array) packages use an array of solder balls on the underside for electrical connections, offering superior thermal performance and higher pin density in a compact footprint. Your choice between QFP and BGA depends on factors like board space, thermal management needs, and assembly complexity.

Key Differences Between QFP and BGA

QFP (Quad Flat Package) features leads extending from all four sides, enabling easier visual inspection and soldering, while BGA (Ball Grid Array) uses an array of solder balls underneath for higher pin density and improved electrical performance. QFP packages generally have lower thermal resistance but are limited in miniaturization compared to BGA, which excels in heat dissipation and signal integrity in compact designs. BGA requires specialized manufacturing equipment due to hidden solder joints, whereas QFP allows manual rework and inspection, influencing selection based on production scale and reliability needs.

Design and Structure Comparison

QFP (Quad Flat Package) features leads extending from all four sides of the rectangular or square body, making it easier to inspect solder joints and ideal for designs with limited board space. BGA (Ball Grid Array) uses an array of tiny solder balls on the underside, providing superior electrical performance and thermal management due to shorter signal paths and better heat dissipation. Your choice between QFP and BGA impacts PCB layout complexity, with QFP offering simpler routing and BGA enabling higher pin counts in compact designs.

Assembly and Soldering Techniques

QFP (Quad Flat Package) assembly involves precise placement and soldering of leads using techniques like reflow soldering with solder paste applied to PCB pads, requiring careful alignment to avoid bridging. BGA (Ball Grid Array) employs solder balls beneath the package that melt during reflow soldering, creating reliable joints and better thermal and electrical performance, but demands X-ray inspection to verify solder quality. Your choice between QFP and BGA affects the complexity of assembly and inspection processes, with BGA offering higher-density connections at the cost of more advanced soldering techniques.

Electrical Performance: QFP vs BGA

Ball Grid Array (BGA) packages exhibit superior electrical performance compared to Quad Flat Packages (QFP) due to shorter lead lengths and lower inductance, resulting in enhanced signal integrity and reduced electromagnetic interference. The uniform heat distribution and minimized parasitic effects in BGA allow for higher frequency operation and improved thermal management. QFPs, with longer leads and exposed leads, tend to have increased signal delay and greater susceptibility to noise, making them less ideal for high-speed, high-density applications.

Reliability and Thermal Management

QFP (Quad Flat Package) generally offers easier visual inspection and solder joint repair, enhancing reliability in low to moderate thermal stress environments. BGA (Ball Grid Array) provides superior thermal management due to its efficient heat dissipation through solder balls and a smaller footprint, which reduces thermal resistance significantly. Your choice between QFP and BGA should consider application-specific reliability demands and thermal performance requirements for optimal efficiency.

Application Areas for QFP and BGA

QFP (Quad Flat Package) is widely used in consumer electronics, automotive applications, and industrial equipment due to its ease of soldering and inspection. BGA (Ball Grid Array) suits high-performance computing, telecommunications, and advanced medical devices, offering superior thermal and electrical performance for complex circuits. Your choice between QFP and BGA depends on the required device density, thermal management, and reliability for your specific application.

Cost Considerations and Availability

QFP (Quad Flat Package) generally incurs lower manufacturing costs compared to BGA (Ball Grid Array) due to simpler assembly and inspection processes, making it cost-effective for low to medium volume production. BGA packages, while typically more expensive, offer higher pin density and improved electrical performance, which can justify the investment in high-performance or space-constrained applications. QFP components are widely available and supported by numerous suppliers, but BGAs may have limited availability depending on specific device requirements and advanced packaging needs.

Pros and Cons of QFP Packages

QFP (Quad Flat Package) offers advantages like ease of inspection and rework due to its exposed leads and relatively simple soldering process, making it suitable for prototypes and repairs. However, QFP packages are prone to lead damage during handling and have lower pin density compared to BGA (Ball Grid Array), which limits their use in high-performance, compact designs. Your choice depends on the balance between manufacturing complexity and circuit density, with QFP being ideal for lower-cost and straightforward applications.

Pros and Cons of BGA Packages

BGA packages offer superior thermal and electrical performance due to their array of solder balls that provide better heat dissipation and shorter interconnect paths compared to QFPs, making them ideal for high-density applications. However, BGA components require precise soldering equipment and inspection methods, increasing manufacturing complexity and cost, while rework is more challenging than with QFPs. Your choice of package should consider these factors alongside your design's thermal, electrical, and space requirements.

QFP vs BGA Infographic

libmatt.com

libmatt.com