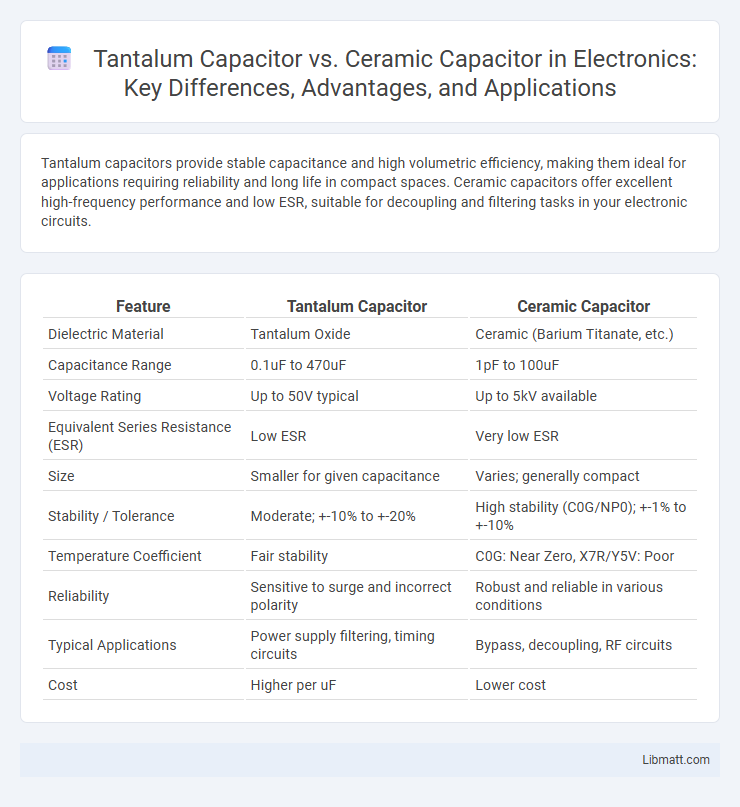

Tantalum capacitors provide stable capacitance and high volumetric efficiency, making them ideal for applications requiring reliability and long life in compact spaces. Ceramic capacitors offer excellent high-frequency performance and low ESR, suitable for decoupling and filtering tasks in your electronic circuits.

Table of Comparison

| Feature | Tantalum Capacitor | Ceramic Capacitor |

|---|---|---|

| Dielectric Material | Tantalum Oxide | Ceramic (Barium Titanate, etc.) |

| Capacitance Range | 0.1uF to 470uF | 1pF to 100uF |

| Voltage Rating | Up to 50V typical | Up to 5kV available |

| Equivalent Series Resistance (ESR) | Low ESR | Very low ESR |

| Size | Smaller for given capacitance | Varies; generally compact |

| Stability / Tolerance | Moderate; +-10% to +-20% | High stability (C0G/NP0); +-1% to +-10% |

| Temperature Coefficient | Fair stability | C0G: Near Zero, X7R/Y5V: Poor |

| Reliability | Sensitive to surge and incorrect polarity | Robust and reliable in various conditions |

| Typical Applications | Power supply filtering, timing circuits | Bypass, decoupling, RF circuits |

| Cost | Higher per uF | Lower cost |

Introduction to Tantalum and Ceramic Capacitors

Tantalum capacitors use tantalum metal as the anode material, offering high capacitance per volume and stable performance in low-voltage applications. Ceramic capacitors feature a ceramic dielectric, providing excellent high-frequency characteristics and low equivalent series resistance (ESR). Your choice depends on specific requirements like capacitance stability, size constraints, and temperature tolerance in electronic circuits.

Construction and Material Differences

Tantalum capacitors use a tantalum metal anode coated with an oxide layer acting as the dielectric, while ceramic capacitors consist of a ceramic dielectric material sandwiched between metal electrodes. Tantalum capacitors typically feature a solid manganese dioxide or conductive polymer cathode, enhancing stability and reliability, whereas ceramic capacitors rely on multiple ceramic layers for capacitance in multilayer ceramic capacitors (MLCCs). The intrinsic material properties of tantalum provide higher volumetric efficiency and stable capacitance, whereas ceramic capacitors offer broader voltage ranges and temperature characteristics due to their diverse ceramic compositions.

Capacitance Range and Voltage Ratings

Tantalum capacitors typically offer capacitance values ranging from 0.1 uF to 470 uF with voltage ratings up to 50V, making them suitable for compact, high-capacitance applications. Ceramic capacitors provide a broader capacitance range from a few picofarads to several microfarads and can handle higher voltage ratings, often exceeding 1 kV, ideal for high-frequency and high-voltage circuits. Your choice depends on the required capacitance and voltage tolerance, with tantalum capacitors favored for stable capacitance in low-voltage environments and ceramic capacitors preferred for higher voltage or high-frequency performance.

Performance in Circuit Applications

Tantalum capacitors offer high capacitance stability and low Equivalent Series Resistance (ESR), making them ideal for filtering and energy storage in low-voltage, high-reliability circuits. Ceramic capacitors excel in high-frequency applications due to their low inductance and superior temperature stability, providing excellent decoupling performance. Your choice depends on circuit requirements: use tantalum capacitors where stable capacitance and longevity are critical, while ceramic capacitors suit high-frequency noise suppression and signal integrity.

Reliability and Longevity Comparison

Tantalum capacitors offer superior reliability and longevity due to their stable capacitance and resistance to moisture, making them ideal for critical applications where long-term performance is essential. Ceramic capacitors, while highly reliable in general, can exhibit microcracking over time from mechanical stress and temperature cycling, potentially reducing their lifespan. Choosing your capacitor type depends on whether ultra-reliable, long-lasting performance (tantalum) or cost-effective, versatile use (ceramic) aligns better with your application's durability requirements.

Size and Packaging Options

Tantalum capacitors typically offer higher capacitance values in smaller packages compared to ceramic capacitors, making them ideal for space-constrained applications. While ceramic capacitors are available in a wider range of standard sizes such as 0402, 0603, and 0805, tantalum capacitors generally come in compact, molded epoxy packages like A, B, and C case sizes. The robust packaging of tantalum capacitors provides superior stability and reliability under varying environmental conditions, whereas ceramic capacitors often feature multilayer chip designs that accommodate high-frequency applications with low equivalent series resistance (ESR).

Temperature Stability and Tolerance

Tantalum capacitors exhibit excellent temperature stability with capacitance variation typically within +-10% over a wide temperature range, making them suitable for applications requiring precise performance under thermal stress. Ceramic capacitors, especially Class II and III types, show higher capacitance variation with temperature, often exceeding +-15%, but Class I ceramics provide superior stability with tolerance as tight as +-5%. Tolerance in tantalum capacitors generally ranges from +-5% to +-20%, while ceramic capacitors offer a broader tolerance spectrum from +-1% to +-20%, depending on the dielectric class and manufacturing process.

Cost and Availability

Tantalum capacitors generally cost more than ceramic capacitors due to the scarcity and higher processing costs of tantalum material. Ceramic capacitors are widely available and produced in large volumes, making them more affordable and easier to source globally. The cost-effectiveness and accessibility of ceramic capacitors make them a preferred choice for mass-market electronic applications.

Common Use Cases and Industries

Tantalum capacitors are commonly used in aerospace, medical devices, and high-reliability electronics due to their stable capacitance and excellent performance under extreme conditions. Ceramic capacitors are preferred in consumer electronics, automotive systems, and telecommunications for their low cost, high-frequency response, and compact size. Your choice depends on the application's requirements for reliability, size, and electrical characteristics.

Choosing the Right Capacitor for Your Application

Tantalum capacitors offer high capacitance density and stable performance in low-voltage applications, making them ideal for power supply filtering and decoupling in compact devices. Ceramic capacitors provide excellent high-frequency characteristics, low equivalent series resistance (ESR), and wide voltage ranges suitable for RF circuits and general-purpose use. When choosing the right capacitor for your application, consider factors such as voltage rating, capacitance value, size constraints, and environmental conditions to optimize circuit reliability and efficiency.

Tantalum capacitor vs Ceramic capacitor Infographic

libmatt.com

libmatt.com