Choosing between an air-cooled and water-cooled condenser depends on your system's efficiency needs and environmental conditions; air-cooled condensers are easier to maintain and ideal for dry climates, while water-cooled condensers offer superior performance and cooling capacity, especially in large HVAC applications where water availability is not a concern. Your decision should consider factors like installation costs, space constraints, and local water usage regulations to ensure optimal system performance and sustainability.

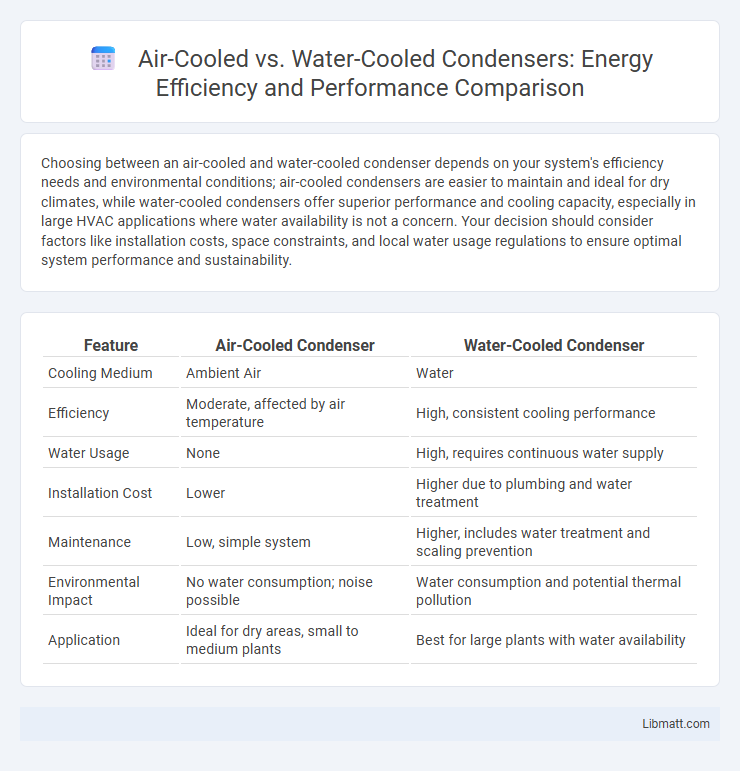

Table of Comparison

| Feature | Air-Cooled Condenser | Water-Cooled Condenser |

|---|---|---|

| Cooling Medium | Ambient Air | Water |

| Efficiency | Moderate, affected by air temperature | High, consistent cooling performance |

| Water Usage | None | High, requires continuous water supply |

| Installation Cost | Lower | Higher due to plumbing and water treatment |

| Maintenance | Low, simple system | Higher, includes water treatment and scaling prevention |

| Environmental Impact | No water consumption; noise possible | Water consumption and potential thermal pollution |

| Application | Ideal for dry areas, small to medium plants | Best for large plants with water availability |

Introduction to Condenser Cooling Methods

Condenser cooling methods include air-cooled and water-cooled systems, each designed to efficiently transfer heat from refrigerant vapors. Air-cooled condensers use ambient air to dissipate heat through fins and fans, making them ideal for applications with limited water availability. Water-cooled condensers employ chilled water or cooling towers to absorb and remove heat, providing higher thermal efficiency in large-scale HVAC and industrial systems.

Overview of Air-Cooled Condensers

Air-cooled condensers use ambient air to dissipate heat from the refrigerant, making them ideal for locations with limited water resources or strict water usage regulations. These condensers typically feature finned tubes and fans to enhance heat transfer efficiency and reduce operating costs. Their maintenance requirements are generally lower compared to water-cooled systems, but their performance can be affected by high ambient temperatures.

Overview of Water-Cooled Condensers

Water-cooled condensers utilize water as the cooling medium to absorb heat from refrigerant vapors, enabling efficient heat transfer and condensation. These condensers typically require a cooling tower and a circulation system, making them suitable for large-scale industrial applications with high cooling loads. Their design offers superior thermal performance and energy efficiency compared to air-cooled systems, especially in hot and humid environments.

Key Differences Between Air-Cooled and Water-Cooled Condensers

Air-cooled condensers use ambient air to dissipate heat, making them simpler to install and maintain, while water-cooled condensers rely on water for heat transfer, offering higher efficiency and better performance in large-scale cooling systems. Air-cooled units typically require less water and are more suited for areas with water scarcity, whereas water-cooled condensers demand regular water treatment and pumping systems to prevent scaling and corrosion. Your choice between these condenser types depends on factors like environmental conditions, water availability, space constraints, and energy efficiency requirements.

Energy Efficiency Comparison

Water-cooled condensers generally exhibit higher energy efficiency compared to air-cooled condensers due to their superior heat transfer capabilities and lower condensing temperatures, which reduce compressor work. Air-cooled condensers consume more energy as they rely on ambient air for heat rejection, which is less effective, especially in high-temperature environments. The choice between the two impacts operational costs and system performance, with water-cooled systems favored in large-scale HVAC or industrial applications for reducing energy consumption.

Installation and Maintenance Requirements

Air-cooled condensers typically require less complex installation due to their straightforward setup without the need for plumbing or water supply connections. Maintenance for air-cooled units mainly involves cleaning fins and ensuring adequate airflow to prevent dirt buildup and overheating. Water-cooled condensers demand more intensive installation, including water piping, pumps, and cooling towers, while their maintenance involves regular monitoring of water quality, descaling, and corrosion control to ensure efficient operation.

Environmental Impact Assessment

Air-cooled condensers typically have a lower environmental impact due to their reduced water consumption, making them suitable for regions facing water scarcity. Water-cooled condensers generally offer higher energy efficiency but require significant water usage and management, which can lead to ecological concerns such as thermal pollution and water resource depletion. Assess Your facility's location and resource availability carefully to balance operational efficiency with environmental sustainability.

Cost Considerations: Initial and Operational

Air-cooled condensers generally have lower initial costs due to simpler installation and lack of water infrastructure, making them ideal for locations with limited water availability. Water-cooled condensers, while incurring higher upfront expenses for pumps, cooling towers, and water treatment, often provide better operational efficiency, reducing energy costs over time. Your choice should consider long-term operational savings versus initial budget constraints and site-specific resource availability.

Applications and Best Use Cases

Air-cooled condensers are commonly used in residential and commercial HVAC systems where space and water availability are limited, providing efficient cooling without the need for additional water resources. Water-cooled condensers excel in large industrial applications and high-capacity cooling systems due to their superior thermal performance and energy efficiency, especially in environments with access to abundant water supplies. Your choice depends on factors like installation space, water availability, and cooling load requirements to ensure optimal system performance.

Choosing the Right Condenser for Your Needs

Selecting the right condenser depends on factors such as efficiency, cost, and application requirements. Air-cooled condensers offer easier installation and lower maintenance, ideal for smaller systems or locations with water scarcity. Water-cooled condensers provide superior heat transfer and energy efficiency, making them suitable for large-scale industrial applications with access to sufficient water resources.

Air-Cooled vs Water-Cooled Condenser Infographic

libmatt.com

libmatt.com