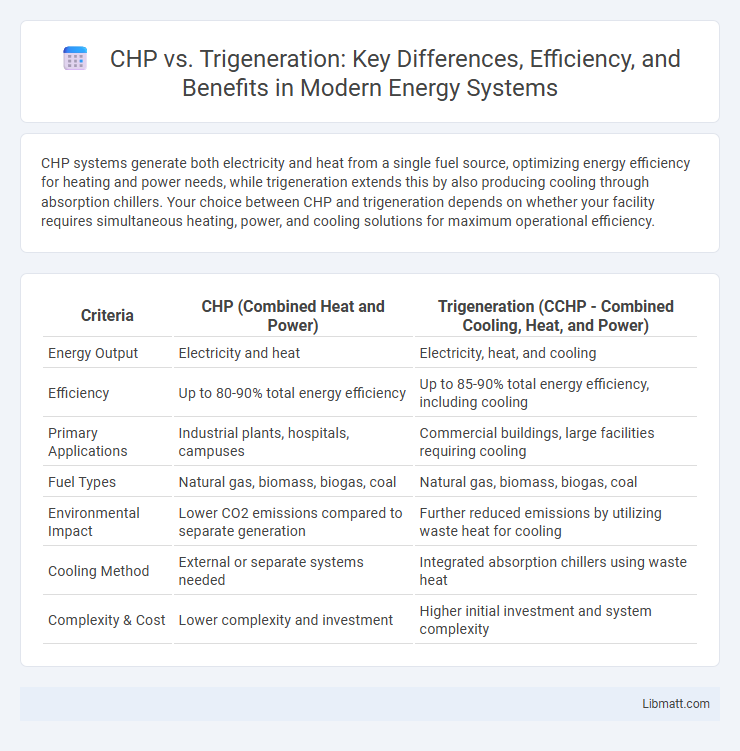

CHP systems generate both electricity and heat from a single fuel source, optimizing energy efficiency for heating and power needs, while trigeneration extends this by also producing cooling through absorption chillers. Your choice between CHP and trigeneration depends on whether your facility requires simultaneous heating, power, and cooling solutions for maximum operational efficiency.

Table of Comparison

| Criteria | CHP (Combined Heat and Power) | Trigeneration (CCHP - Combined Cooling, Heat, and Power) |

|---|---|---|

| Energy Output | Electricity and heat | Electricity, heat, and cooling |

| Efficiency | Up to 80-90% total energy efficiency | Up to 85-90% total energy efficiency, including cooling |

| Primary Applications | Industrial plants, hospitals, campuses | Commercial buildings, large facilities requiring cooling |

| Fuel Types | Natural gas, biomass, biogas, coal | Natural gas, biomass, biogas, coal |

| Environmental Impact | Lower CO2 emissions compared to separate generation | Further reduced emissions by utilizing waste heat for cooling |

| Cooling Method | External or separate systems needed | Integrated absorption chillers using waste heat |

| Complexity & Cost | Lower complexity and investment | Higher initial investment and system complexity |

Introduction to CHP and Trigeneration

Combined Heat and Power (CHP) systems simultaneously generate electricity and useful thermal energy from a single fuel source, enhancing energy efficiency compared to conventional power generation. Trigeneration, also known as combined cooling, heat, and power (CCHP), extends CHP by producing electricity, heat, and cooling, typically through absorption chillers powered by the waste heat. Both technologies optimize fuel utilization but trigeneration offers greater energy flexibility and substantial reductions in carbon footprint for applications requiring simultaneous heating and cooling.

How CHP Systems Work

CHP (Combined Heat and Power) systems generate electricity and capture usable heat simultaneously from a single fuel source, significantly increasing energy efficiency. These systems convert fuel into mechanical energy via a prime mover, such as an engine or turbine, which drives a generator to produce electricity while recovering thermal energy for heating purposes. Your facility can reduce energy costs and emissions by utilizing the recovered heat for space heating, hot water, or industrial processes.

Overview of Trigeneration Technology

Trigeneration technology simultaneously produces electricity, heat, and cooling by integrating combined heat and power (CHP) systems with absorption chillers. This advanced process improves overall energy efficiency by utilizing waste heat not only for heating but also to drive cooling cycles, reducing energy consumption and costs. Understanding trigeneration can help you optimize energy use in commercial or industrial applications, achieving greater sustainability and operational savings.

Key Differences Between CHP and Trigeneration

Combined Heat and Power (CHP) systems generate electricity and capture usable heat simultaneously, enhancing energy efficiency by utilizing waste heat for heating purposes. Trigeneration, or Combined Cooling, Heat, and Power (CCHP), expands on CHP by incorporating an absorption chiller to convert waste heat into cooling, providing electricity, heating, and cooling from a single fuel source. The key difference lies in trigeneration's ability to produce cooling alongside electricity and heat, offering greater flexibility and energy savings in applications requiring air conditioning.

Efficiency Comparison

Combined Heat and Power (CHP) systems typically achieve efficiencies of 75-85% by simultaneously generating electricity and useful heat, maximizing fuel utilization. Trigeneration systems, also known as Combined Cooling, Heat, and Power (CCHP), extend this efficiency by producing cooling through absorption chillers, often raising total system efficiency to 80-90%. Your choice between CHP and trigeneration should consider the demand for cooling alongside heating and power to optimize overall energy savings.

Environmental Impact Assessment

Combined Heat and Power (CHP) systems reduce greenhouse gas emissions by simultaneously generating electricity and useful heat from a single fuel source, achieving higher energy efficiency compared to conventional methods. Trigeneration enhances this efficiency further by producing cooling alongside heat and power, significantly lowering overall carbon footprints in buildings and industrial processes. Environmental impact assessments show trigeneration systems typically deliver greater reductions in CO2 emissions, water usage, and pollutant outputs, making them more sustainable solutions for integrated energy management.

Applications and Use Cases

CHP (Combined Heat and Power) systems efficiently generate electricity and useful heat simultaneously, ideal for industrial facilities, hospitals, and large residential complexes with consistent thermal and electrical demands. Trigeneration extends CHP by producing cooling in addition to heat and power, making it highly suitable for commercial buildings, data centers, and campuses requiring simultaneous heating, cooling, and electricity. Your choice between CHP and Trigeneration depends on the specific energy needs and load profiles of your facility, optimizing energy use and reducing operational costs.

Economic Considerations and Cost Analysis

CHP (Combined Heat and Power) systems typically present lower initial capital costs compared to trigeneration, which integrates cooling alongside heat and power generation, leading to higher upfront investment. Operating expenses for trigeneration are often reduced due to increased overall energy efficiency and the ability to offset separate cooling costs, improving long-term economic viability. Your decision should weigh the balance between the higher capital expenditure of trigeneration against potential energy savings and cost reductions in cooling, influencing payback periods and total cost of ownership.

Challenges and Limitations

CHP systems face challenges such as fuel availability, high initial costs, and complex integration with existing infrastructure, limiting their widespread adoption. Trigeneration systems add complexity by requiring advanced control strategies to balance simultaneous electricity, heating, and cooling demands efficiently. Your operational efficiency may be impacted by these limitations, necessitating careful feasibility analysis and tailored solutions.

Choosing the Right System for Your Needs

Combined Heat and Power (CHP) systems efficiently generate electricity and utilize waste heat for heating, making them ideal for facilities with consistent heating demands. Trigeneration expands on CHP by also producing cooling through absorption chillers, offering versatile energy solutions for buildings requiring heating, electricity, and cooling simultaneously. Selecting the right system depends on your specific energy consumption patterns, operational needs, and climate conditions to maximize efficiency and cost savings.

CHP vs Trigeneration Infographic

libmatt.com

libmatt.com