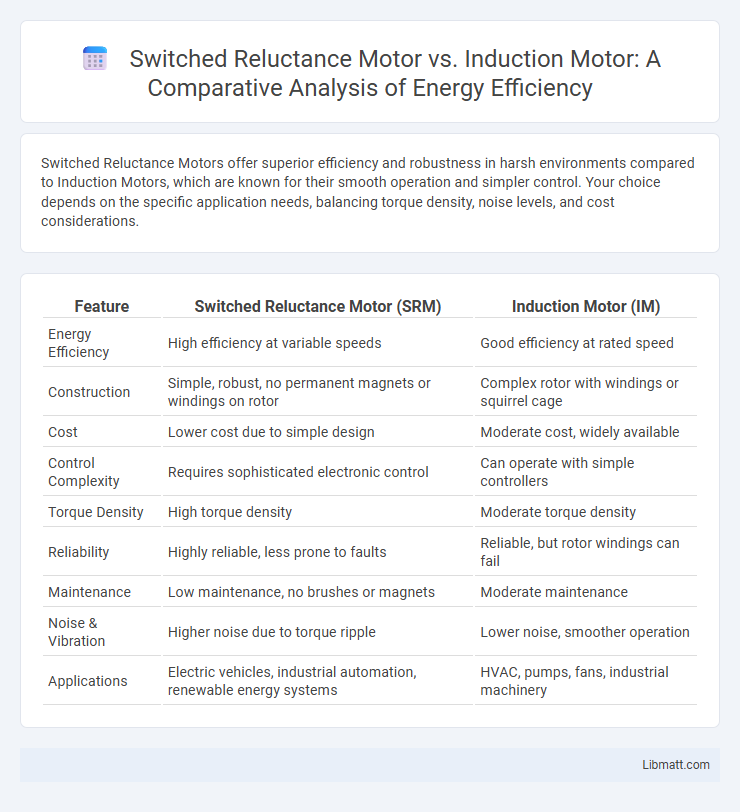

Switched Reluctance Motors offer superior efficiency and robustness in harsh environments compared to Induction Motors, which are known for their smooth operation and simpler control. Your choice depends on the specific application needs, balancing torque density, noise levels, and cost considerations.

Table of Comparison

| Feature | Switched Reluctance Motor (SRM) | Induction Motor (IM) |

|---|---|---|

| Energy Efficiency | High efficiency at variable speeds | Good efficiency at rated speed |

| Construction | Simple, robust, no permanent magnets or windings on rotor | Complex rotor with windings or squirrel cage |

| Cost | Lower cost due to simple design | Moderate cost, widely available |

| Control Complexity | Requires sophisticated electronic control | Can operate with simple controllers |

| Torque Density | High torque density | Moderate torque density |

| Reliability | Highly reliable, less prone to faults | Reliable, but rotor windings can fail |

| Maintenance | Low maintenance, no brushes or magnets | Moderate maintenance |

| Noise & Vibration | Higher noise due to torque ripple | Lower noise, smoother operation |

| Applications | Electric vehicles, industrial automation, renewable energy systems | HVAC, pumps, fans, industrial machinery |

Introduction to Switched Reluctance Motors and Induction Motors

Switched Reluctance Motors (SRMs) feature a simple, robust construction with salient poles on both stator and rotor, allowing high fault tolerance and efficiency in variable speed applications. Induction Motors operate on electromagnetic induction principles, with a squirrel-cage rotor, widely used in industrial drives due to their low cost and reliability. Your choice between SRM and Induction Motor depends on factors like control complexity, efficiency requirements, and application-specific demands.

Fundamental Working Principles

Switched Reluctance Motors (SRMs) operate based on the principle of variable reluctance, where torque is generated by magnetic forces aligning the rotor's salient poles with the stator's energized poles. Induction Motors function through electromagnetic induction, where a rotating magnetic field in the stator induces currents in the rotor, producing torque via interaction with the stator's magnetic field. The fundamental difference lies in SRMs using reluctance torque without rotor windings, while Induction Motors rely on induced currents in rotor conductors.

Construction Differences

The Switched Reluctance Motor (SRM) features a simple construction with a salient pole rotor made of laminated steel without windings or permanent magnets, contrasting with the Induction Motor (IM) that has a squirrel cage rotor consisting of aluminum or copper bars short-circuited by end rings. SRM stators have concentrated windings on salient poles, while IM stators contain distributed windings creating a rotating magnetic field. The absence of rotor windings in SRMs leads to a rugged, cost-effective design with enhanced reliability compared to the rotor construction of induction motors.

Efficiency Comparison

Switched Reluctance Motors (SRMs) typically exhibit higher efficiency at low to medium speeds due to their simple construction and reduced rotor losses compared to Induction Motors (IMs). Induction Motors, however, often maintain more consistent efficiency across a wider speed range due to their smooth torque production and established design optimizations. Efficiency in SRMs can exceed 90% under optimal control strategies, while IM efficiencies generally range between 85% and 95% depending on size and load conditions.

Performance Characteristics

Switched Reluctance Motors (SRMs) exhibit high reliability and robust performance under harsh conditions with a simple construction and superior fault tolerance, making them suitable for applications requiring high-speed operation and low maintenance. Induction Motors offer smooth torque output and high efficiency at a wide range of speeds, benefiting from well-established control techniques and widespread industrial use. SRMs often outperform Induction Motors in terms of torque density and thermal robustness, while Induction Motors excel in energy efficiency and low acoustic noise during operation.

Control Systems and Complexity

Switched Reluctance Motors (SRMs) require advanced control systems with precise current regulation to manage their nonlinear magnetic characteristics, resulting in higher complexity compared to Induction Motors (IMs). Induction Motors use simpler control algorithms such as scalar or vector control, benefiting from well-established models and smoother torque production. The complexity of SRM drives stems from the need for rapid switching and position sensing, demanding sophisticated electronics and real-time processing for optimal performance.

Cost and Maintenance Requirements

Switched Reluctance Motors (SRMs) generally have lower manufacturing costs due to their simple and robust rotor structure, which eliminates the need for magnets or windings. Induction Motors, while slightly more expensive upfront, benefit from widespread availability of parts and established maintenance procedures, resulting in predictable upkeep expenses. Maintenance of SRMs tends to be less frequent but requires specialized knowledge due to their unique control systems, whereas Induction Motors have well-understood maintenance protocols, making them easier and often cheaper to service over time.

Applications in Industry

Switched Reluctance Motors excel in industrial applications requiring high efficiency and robustness, such as robotics, electric vehicles, and aerospace systems due to their simple construction and fault tolerance. Induction Motors dominate heavy-duty applications like pumps, compressors, and conveyor systems because of their reliable performance and cost-effectiveness in continuous operation. Your choice depends on specific needs for precision control or durability under harsh conditions.

Advantages and Disadvantages

Switched reluctance motors (SRMs) offer advantages such as a simple and robust construction, high reliability, and excellent performance at high speeds due to their rotor's absence of windings or permanent magnets. Induction motors provide smooth operation, high efficiency under steady loads, and widespread industrial use with mature control technology but tend to have lower starting torque and issues with rotor heating. SRMs face challenges like higher acoustic noise and torque ripple, while induction motors require complex variable frequency drives to achieve precise speed control.

Future Trends and Technological Developments

Switched reluctance motors (SRMs) are gaining traction due to advancements in power electronics and improved control algorithms, enabling higher efficiency and reliability compared to traditional induction motors. Future trends include integration with smart grid technology and the development of magnetic materials that reduce torque ripple and acoustic noise in SRMs. Your choice between SRM and induction motor will increasingly depend on application-specific requirements, such as energy efficiency, performance under variable loads, and ease of maintenance.

Switched Reluctance Motor vs Induction Motor Infographic

libmatt.com

libmatt.com