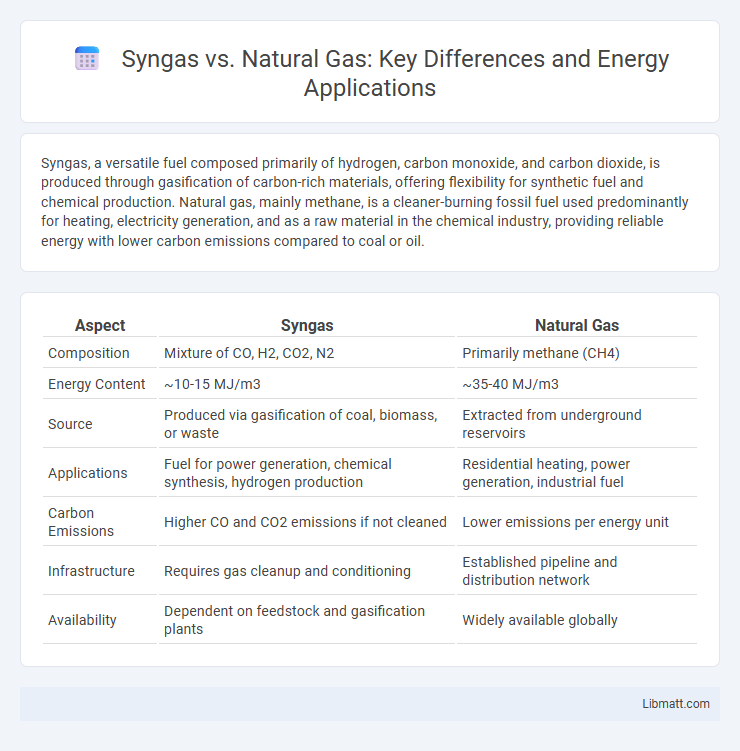

Syngas, a versatile fuel composed primarily of hydrogen, carbon monoxide, and carbon dioxide, is produced through gasification of carbon-rich materials, offering flexibility for synthetic fuel and chemical production. Natural gas, mainly methane, is a cleaner-burning fossil fuel used predominantly for heating, electricity generation, and as a raw material in the chemical industry, providing reliable energy with lower carbon emissions compared to coal or oil.

Table of Comparison

| Aspect | Syngas | Natural Gas |

|---|---|---|

| Composition | Mixture of CO, H2, CO2, N2 | Primarily methane (CH4) |

| Energy Content | ~10-15 MJ/m3 | ~35-40 MJ/m3 |

| Source | Produced via gasification of coal, biomass, or waste | Extracted from underground reservoirs |

| Applications | Fuel for power generation, chemical synthesis, hydrogen production | Residential heating, power generation, industrial fuel |

| Carbon Emissions | Higher CO and CO2 emissions if not cleaned | Lower emissions per energy unit |

| Infrastructure | Requires gas cleanup and conditioning | Established pipeline and distribution network |

| Availability | Dependent on feedstock and gasification plants | Widely available globally |

Introduction to Syngas and Natural Gas

Syngas, or synthesis gas, is a fuel mixture primarily composed of hydrogen, carbon monoxide, and carbon dioxide, produced through gasification of carbon-containing materials such as coal, biomass, or municipal waste. Natural gas is a fossil fuel consisting mainly of methane (CH4), extracted from underground reservoirs formed by the decomposition of organic matter over millions of years. Both gases serve as important energy sources, with syngas offering versatility in chemical synthesis and power generation, while natural gas is widely used for residential heating, electricity production, and industrial processes.

Composition Differences: Syngas vs Natural Gas

Syngas primarily consists of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2), while natural gas is mainly methane (CH4) with small amounts of ethane, propane, and other hydrocarbons. The lower methane content in syngas results in a different calorific value and combustion characteristics compared to natural gas. Understanding these composition differences helps you optimize combustion systems and fuel applications for each gas type.

Production Methods of Syngas and Natural Gas

Syngas is produced through gasification, a process that converts carbon-rich materials like coal, biomass, or waste into a mixture of hydrogen, carbon monoxide, and carbon dioxide by reacting the feedstock at high temperatures with a controlled amount of oxygen or steam. Natural gas, primarily composed of methane, is extracted from underground reservoirs through drilling and hydraulic fracturing, followed by processing to remove impurities and separate hydrocarbons. Understanding these production methods highlights the distinct origins and compositions of syngas and natural gas, impacting their applications and environmental footprints.

Energy Content Comparison

Syngas typically contains a mixture of hydrogen, carbon monoxide, and some carbon dioxide, resulting in an energy content ranging from 4 to 14 MJ/m3, significantly lower than natural gas's higher heating value of around 35 to 40 MJ/m3. The lower calorific value of syngas is due to its diluted composition and variable gas mixture, which affects combustion efficiency and energy output. Despite its lower energy content, syngas is valuable in integrated gasification combined cycle (IGCC) plants and chemical synthesis, where its composition can be optimized for specific industrial applications.

Environmental Impact and Emissions

Syngas, composed primarily of hydrogen, carbon monoxide, and carbon dioxide, generally produces lower sulfur oxide and particulate emissions compared to natural gas, which consists mostly of methane and can emit higher levels of nitrogen oxides and carbon dioxide during combustion. The production and utilization of syngas often involve gasification of biomass or coal, potentially resulting in higher lifecycle greenhouse gas emissions unless paired with carbon capture technologies. Your choice between syngas and natural gas impacts air quality and carbon footprint, with syngas offering opportunities for cleaner energy when sourced sustainably.

Industrial Applications and Uses

Syngas, composed primarily of hydrogen and carbon monoxide, serves as a versatile feedstock in chemical synthesis, metal refining, and power generation industries. Natural gas, mainly methane, is widely used for heating, electricity generation, and as a feedstock in ammonia and methanol production. While syngas offers flexibility in industrial applications due to its composition, natural gas provides higher energy density and easier storage and transportation.

Cost Analysis: Syngas vs Natural Gas

Syngas production often incurs higher initial capital costs due to complex gasification technologies compared to natural gas extraction and infrastructure. Operational expenses for syngas can vary widely based on feedstock type and processing efficiency, while natural gas benefits from established supply chains and lower per-unit fuel costs. Evaluating your energy project requires balancing syngas's flexibility and sustainability against natural gas's cost-effectiveness and market stability.

Infrastructure and Supply Chain Considerations

Syngas infrastructure requires specialized gasification plants and handling equipment due to its variable composition, while natural gas benefits from an extensive, well-established pipeline network and storage facilities. Supply chain logistics for syngas involve integrating biomass, coal, or waste feedstock sourcing with onsite conversion processes, contrasting with natural gas's direct extraction and distribution from gas fields. Your choice between syngas and natural gas depends on the availability of local feedstocks, existing infrastructure, and the scalability of supply chains for consistent fuel delivery.

Future Prospects and Technological Developments

Syngas, composed primarily of hydrogen and carbon monoxide, offers promising future prospects as a flexible feedstock for producing cleaner fuels and chemicals, especially when derived from renewable biomass or waste gasification. Advances in carbon capture and storage (CCS) technologies and catalytic reforming are enhancing syngas production efficiency and reducing greenhouse gas emissions, positioning it as a key component in decarbonizing the energy sector. In contrast, natural gas faces increasing scrutiny due to methane leakage and fossil fuel dependence, prompting innovations in hydrogen blending and power-to-gas technologies to improve its sustainability profile.

Conclusion: Choosing Between Syngas and Natural Gas

Choosing between syngas and natural gas depends on factors such as feedstock availability, environmental impact, and intended application. Syngas, produced from biomass or coal gasification, offers a flexible and renewable alternative but requires complex cleanup and has lower energy density compared to natural gas. Natural gas, with its higher methane content and established infrastructure, remains the preferred choice for efficient power generation and heating in many regions.

Syngas vs Natural Gas Infographic

libmatt.com

libmatt.com