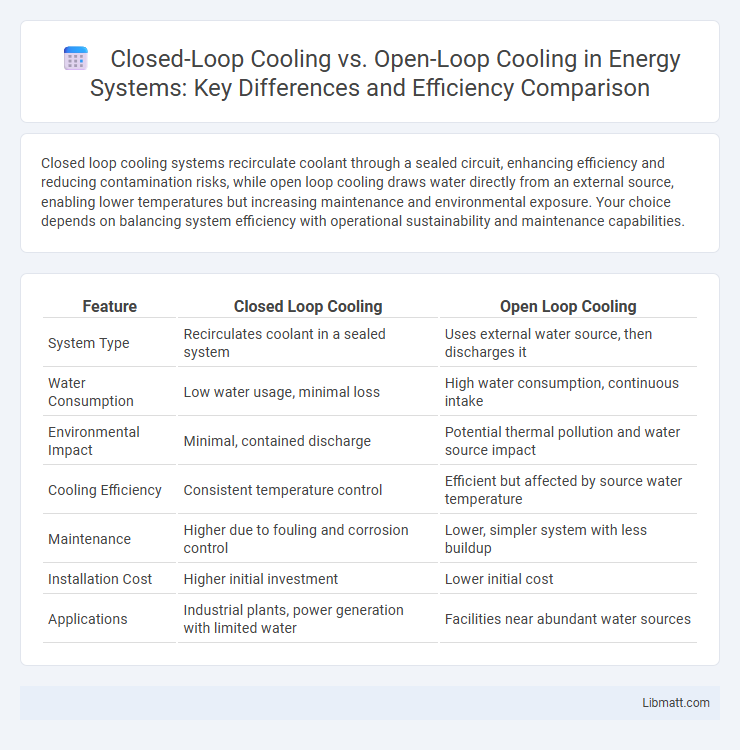

Closed loop cooling systems recirculate coolant through a sealed circuit, enhancing efficiency and reducing contamination risks, while open loop cooling draws water directly from an external source, enabling lower temperatures but increasing maintenance and environmental exposure. Your choice depends on balancing system efficiency with operational sustainability and maintenance capabilities.

Table of Comparison

| Feature | Closed Loop Cooling | Open Loop Cooling |

|---|---|---|

| System Type | Recirculates coolant in a sealed system | Uses external water source, then discharges it |

| Water Consumption | Low water usage, minimal loss | High water consumption, continuous intake |

| Environmental Impact | Minimal, contained discharge | Potential thermal pollution and water source impact |

| Cooling Efficiency | Consistent temperature control | Efficient but affected by source water temperature |

| Maintenance | Higher due to fouling and corrosion control | Lower, simpler system with less buildup |

| Installation Cost | Higher initial investment | Lower initial cost |

| Applications | Industrial plants, power generation with limited water | Facilities near abundant water sources |

Introduction to Cooling Systems

Closed loop cooling systems recycle coolant within a sealed circuit, preventing contamination and improving thermal efficiency, making them ideal for consistent temperature control in engines and industrial equipment. Open loop cooling systems draw water directly from a natural source or external reservoir, which can lead to variable cooling performance and potential environmental impacts due to heat discharge. Your choice between these systems depends on factors like maintenance requirements, environmental regulations, and the specific cooling needs of your application.

What is Closed Loop Cooling?

Closed loop cooling is a thermal management system where coolant circulates within a sealed circuit, preventing exposure to contaminants and evaporation. This system relies on a heat exchanger to transfer heat to the environment without directly contacting external fluids, ensuring consistent cooling efficiency and reduced maintenance. It is commonly used in industrial machinery, automotive engines, and HVAC systems to provide reliable temperature regulation while minimizing environmental impact.

What is Open Loop Cooling?

Open loop cooling uses external water sources, such as rivers or lakes, to absorb heat from a system before discharging it back into the environment, making it energy-efficient but dependent on water quality and availability. Its design allows higher heat rejection rates but may lead to increased environmental impact due to thermal pollution and water consumption. Understanding open loop cooling helps you evaluate if it's suitable for your industrial or HVAC cooling needs based on site-specific water access and regulatory constraints.

Key Differences Between Closed and Open Loop Cooling

Closed loop cooling systems circulate coolant through a sealed loop, preventing contamination and reducing maintenance, while open loop cooling relies on fresh water intake, making it susceptible to debris and environmental factors. Closed loop systems provide consistent temperature control and higher efficiency, whereas open loop systems are generally simpler and less expensive but require regular monitoring. Your choice depends on factors like system complexity, operating environment, and maintenance capabilities.

Efficiency Comparison: Closed vs Open Loop

Closed loop cooling systems offer higher efficiency by continuously recirculating coolant within a sealed environment, minimizing heat loss and contamination compared to open loop systems that rely on external water sources. Your equipment benefits from stable temperature control in closed loop setups, reducing energy consumption and maintenance costs. Open loop cooling can be less efficient due to variable water quality and temperature fluctuations, leading to potential scaling and corrosion issues.

Maintenance Requirements

Closed loop cooling systems require less frequent maintenance due to their sealed design, which prevents contamination and reduces the need for regular coolant replacement. Open loop cooling systems demand more consistent upkeep, including cleaning, flushing, and water quality monitoring to prevent corrosion and fouling. Your choice between these systems impacts long-term maintenance effort and operational reliability.

Cost Analysis and Budget Considerations

Closed loop cooling systems generally involve higher initial costs due to the complexity and use of specialized components, but offer long-term savings through lower water consumption and reduced maintenance expenses. Open loop cooling systems have lower upfront expenses but can incur higher operational costs over time due to water usage, treatment, and potential environmental compliance fees. When evaluating your budget, consider both the initial investment and ongoing operational costs to determine which cooling system aligns best with your financial goals.

Environmental Impact and Water Usage

Closed loop cooling systems significantly reduce water usage by recirculating coolant within a sealed circuit, minimizing water withdrawal and lowering the risk of thermal pollution in natural water bodies. Open loop cooling relies on continuous intake and discharge of large volumes of water, often leading to higher environmental impact through thermal contamination and ecosystem disruption. By choosing closed loop cooling, your operation can achieve greater sustainability with efficient water conservation and reduced ecological footprint.

Application Suitability: Residential, Commercial, and Industrial

Closed loop cooling systems are ideal for residential and commercial applications where water conservation and contamination prevention are priorities due to their sealed design. Open loop cooling is better suited for industrial settings with abundant water sources, offering higher efficiency but requiring careful water quality management. Your selection should consider the specific operational environment and maintenance capacity of the facility to optimize performance and sustainability.

Choosing the Right Cooling System for Your Needs

Closed loop cooling systems offer higher efficiency and reduced maintenance by recycling coolant within a sealed environment, making them ideal for precision applications and environments with contamination risks. Open loop cooling systems, which draw and discharge water from external sources, provide cost-effective and straightforward solutions suitable for large-scale industrial or agricultural settings with ample water availability. Selecting the right system depends on factors such as cooling capacity, environmental conditions, water availability, maintenance preferences, and initial investment cost.

Closed loop cooling vs Open loop cooling Infographic

libmatt.com

libmatt.com