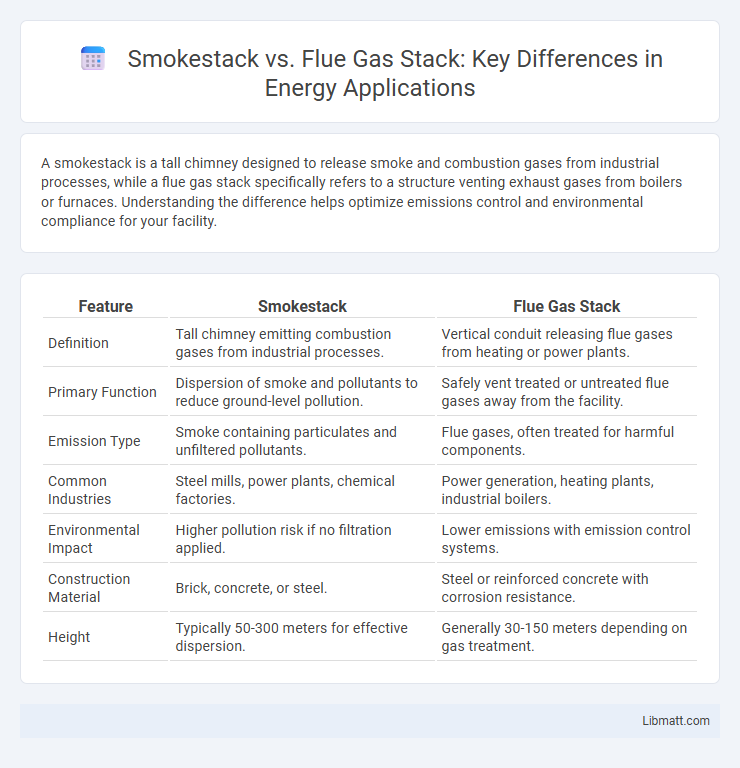

A smokestack is a tall chimney designed to release smoke and combustion gases from industrial processes, while a flue gas stack specifically refers to a structure venting exhaust gases from boilers or furnaces. Understanding the difference helps optimize emissions control and environmental compliance for your facility.

Table of Comparison

| Feature | Smokestack | Flue Gas Stack |

|---|---|---|

| Definition | Tall chimney emitting combustion gases from industrial processes. | Vertical conduit releasing flue gases from heating or power plants. |

| Primary Function | Dispersion of smoke and pollutants to reduce ground-level pollution. | Safely vent treated or untreated flue gases away from the facility. |

| Emission Type | Smoke containing particulates and unfiltered pollutants. | Flue gases, often treated for harmful components. |

| Common Industries | Steel mills, power plants, chemical factories. | Power generation, heating plants, industrial boilers. |

| Environmental Impact | Higher pollution risk if no filtration applied. | Lower emissions with emission control systems. |

| Construction Material | Brick, concrete, or steel. | Steel or reinforced concrete with corrosion resistance. |

| Height | Typically 50-300 meters for effective dispersion. | Generally 30-150 meters depending on gas treatment. |

Introduction to Smokestacks and Flue Gas Stacks

Smokestacks and flue gas stacks both serve as essential components in industrial emission systems, designed to safely release combustion gases into the atmosphere. A smokestack typically refers to a tall chimney that disperses smoke and pollutants from factories or power plants, while a flue gas stack specifically handles exhaust gases from boilers, furnaces, or gas turbines. Understanding the differences between these stacks is crucial for optimizing your facility's air pollution control and environmental compliance.

Definition of Smokestack

A smokestack is a tall, vertical structure designed to disperse smoke and combustion gases from industrial processes or power plants into the atmosphere, minimizing local air pollution. It functions by increasing the velocity and height of the exhaust, which helps in reducing the impact of pollutants at ground level. Unlike flue gas stacks, which may specifically refer to conduits for gas flow within a boiler system, smokestacks are primarily associated with emissions released at a facility's exit point.

Definition of Flue Gas Stack

A flue gas stack is a vertical structure designed to safely discharge combustion gases from industrial processes or power plants into the atmosphere, ensuring pollutants are dispersed at a height to reduce ground-level pollution. Unlike a smokestack, which specifically refers to stacks emitting smoke from burning fuel, a flue gas stack handles a broader range of gas emissions, including treated flue gases after pollution control equipment. Understanding the definition of a flue gas stack helps you select the appropriate exhaust system for environmental compliance and operational efficiency.

Key Functional Differences

Smokestacks are designed primarily to release combustion gases from industrial processes or power plants into the atmosphere, ensuring pollutant dispersion and minimizing ground-level contamination. Flue gas stacks specifically handle the exhaust gases from combustion equipment like boilers or furnaces, often incorporating advanced emission control technologies to reduce pollutants such as sulfur dioxide and nitrogen oxides. The key functional difference lies in their operational focus: smokestacks serve broader industrial exhaust needs, while flue gas stacks are specialized for controlled release and treatment of combustion flue gases.

Materials and Construction Methods

Smokestacks and flue gas stacks differ in materials and construction methods based on their specific industrial applications and temperature requirements. Smokestacks typically use reinforced concrete or steel with corrosion-resistant linings to withstand high temperatures and acidic gases, while flue gas stacks often incorporate stainless steel or acid-resistant alloys to resist chemical degradation from combustion byproducts. Construction of smokestacks involves modular assembly for height and stability, whereas flue gas stacks prioritize airtight welding and seamless joints to prevent gas leaks and ensure environmental compliance.

Industrial Applications of Each Stack Type

Smokestacks are primarily used in industrial applications such as power plants and manufacturing facilities to release combustion gases and particulate matter safely into the atmosphere. Flue gas stacks serve specialized roles in processes like chemical plants and refineries, where they handle exhaust gases that require precise temperature and pollution control. Understanding your facility's emission requirements helps determine the most efficient stack type for environmental compliance and operational performance.

Environmental Impact and Emission Control

Smokestacks and flue gas stacks differ significantly in their environmental impact and emission control capabilities, with flue gas stacks often equipped with advanced filtration systems that reduce harmful pollutants such as sulfur dioxide and particulate matter. Your choice between the two affects air quality compliance and the effectiveness of capturing and treating emissions before release into the atmosphere. Emission control technologies integrated into flue gas stacks help minimize environmental damage, supporting cleaner industrial operations and stricter regulatory adherence.

Efficiency and Performance Comparison

Smokestacks and flue gas stacks both serve to expel combustion gases but differ significantly in efficiency and performance. Flue gas stacks are designed with advanced materials and technologies like scrubbers and filters, enhancing pollutant removal and improving overall emission control compared to traditional smokestacks. Optimizing your industrial exhaust system with a flue gas stack can result in better environmental compliance and higher operational efficiency.

Regulatory Standards and Compliance

Regulatory standards for smokestacks and flue gas stacks are governed by the Environmental Protection Agency (EPA) and other local authorities, focusing on emission limits, stack height, and pollution control technologies to ensure air quality compliance. Flue gas stacks often require stringent monitoring of specific pollutants such as sulfur dioxide (SO2) and nitrogen oxides (NOx), aligning with the Clean Air Act regulations, whereas smokestacks may have broader industrial emission controls depending on the source. Your facility must meet these regulatory requirements by implementing appropriate filtration systems and continuous emissions monitoring to avoid penalties and maintain environmental responsibility.

Choosing the Right Stack for Your Facility

Selecting the right stack for your facility hinges on understanding the primary function of smokestacks versus flue gas stacks; smokestacks are designed to disperse pollutants from combustion sources at high altitudes to reduce local air pollution, while flue gas stacks specifically channel exhaust gases from industrial processes directly to the atmosphere. Consider factors such as emission volume, regulatory requirements, and facility design to optimize stack performance and environmental compliance. Your choice impacts both operational efficiency and adherence to environmental standards, making it essential to match the stack type with your facility's specific emissions profile.

Smokestack vs Flue Gas Stack Infographic

libmatt.com

libmatt.com