Duty cycle measures the percentage of time a system operates within a specific period, reflecting its active duration, while load factor indicates the ratio of actual energy used to the maximum possible energy consumption over the same time, highlighting efficiency. Understanding the difference between duty cycle and load factor can help you optimize energy management and improve system performance.

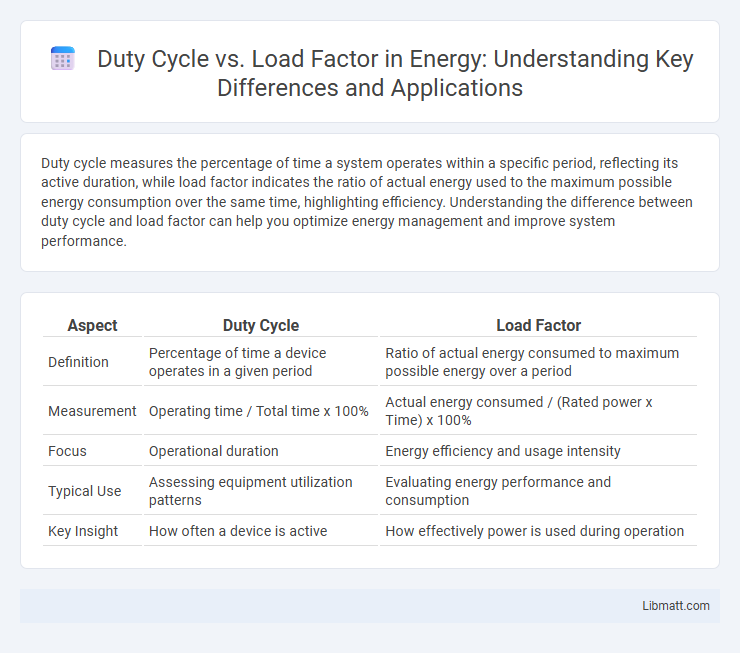

Table of Comparison

| Aspect | Duty Cycle | Load Factor |

|---|---|---|

| Definition | Percentage of time a device operates in a given period | Ratio of actual energy consumed to maximum possible energy over a period |

| Measurement | Operating time / Total time x 100% | Actual energy consumed / (Rated power x Time) x 100% |

| Focus | Operational duration | Energy efficiency and usage intensity |

| Typical Use | Assessing equipment utilization patterns | Evaluating energy performance and consumption |

| Key Insight | How often a device is active | How effectively power is used during operation |

Understanding Duty Cycle: Definition and Importance

Duty cycle refers to the proportion of time a machine or electrical device operates compared to its total available time, expressed as a percentage. It is crucial for assessing equipment performance, ensuring longevity, and preventing overheating or mechanical wear. Understanding duty cycle helps optimize operational efficiency and maintenance schedules in industrial and electrical applications.

What is Load Factor? A Comprehensive Overview

Load Factor measures the efficiency of energy use by comparing the actual energy consumed to the maximum possible energy consumption during a specific period, expressed as a percentage. It indicates how consistently your equipment or system operates at full capacity, reflecting overall performance and cost-effectiveness. Understanding Load Factor helps optimize energy consumption, reduce operational costs, and improve equipment lifespan.

Key Differences Between Duty Cycle and Load Factor

Duty cycle measures the percentage of time a machine operates at full capacity during a specified period, while load factor assesses the average load compared to the maximum possible load over the same timeframe. The key difference lies in duty cycle focusing on operational time at peak output and load factor emphasizing energy utilization efficiency relative to maximum capacity. Understanding these distinctions helps optimize equipment performance and energy management for your operations.

Real-World Examples: Duty Cycle vs Load Factor

In industrial manufacturing, the duty cycle often measures the proportion of time machinery operates at full capacity, such as a welding robot performing repeated tasks with a 50% duty cycle indicating equal active and rest periods. Load factor, by contrast, evaluates the average electrical load against the peak load over a time frame, exemplified in power plants where a 70% load factor reflects consistent energy output relative to maximum capacity. Commercial buildings showcase both concepts: HVAC systems exhibit duty cycles based on their operational patterns, while the load factor captures fluctuations in energy consumption throughout the day to optimize efficiency and reduce costs.

Impact on Equipment Performance and Efficiency

Duty cycle directly influences equipment performance by determining the proportion of time a machine operates versus rests, affecting wear and thermal management. Load factor measures the actual output relative to maximum capacity, impacting energy efficiency and operational costs. Understanding the relationship between duty cycle and load factor helps optimize Your equipment's performance, extending lifespan and reducing energy consumption.

Calculating Duty Cycle: Step-by-Step Guide

Calculating Duty Cycle involves measuring the ratio of the active time of a device to its total operating time, expressed as a percentage. To determine the duty cycle, record the duration the device is operational (on-time) and divide it by the sum of on-time plus off-time, then multiply by 100 for a percentage representation. Understanding this calculation helps you optimize energy efficiency and equipment longevity by aligning duty cycle with the load factor for precise performance management.

Load Factor Calculation Methods Explained

Load factor calculation methods assess the efficiency of energy consumption by comparing actual energy use to maximum potential usage over a given period, typically expressed as a ratio or percentage. Common approaches include ratio-based calculations, where the actual energy consumed is divided by the product of maximum demand and total time, and energy-based methods using integrated power measurements over time intervals. These calculations provide critical insights for optimizing operational schedules, reducing energy costs, and improving overall system performance.

Applications in Industry: Choosing Between Duty Cycle and Load Factor

In industrial applications, understanding the difference between duty cycle and load factor is crucial for optimizing equipment performance and energy efficiency. Duty cycle quantifies the proportion of time a machine operates at full capacity within a given period, helping to prevent overheating and wear in high-intensity processes. Load factor measures the ratio of actual energy used to the maximum possible, guiding you in selecting equipment that balances operational demand with energy consumption for cost-effective manufacturing.

Common Misconceptions and Mistakes to Avoid

Duty cycle often gets confused with load factor, but duty cycle measures the percentage of time equipment is actively operating, while load factor represents the actual energy used compared to maximum possible energy over a period. A common misconception is treating a high duty cycle as equivalent to high energy consumption, ignoring that a low load factor can indicate inefficient operation despite long run times. Avoid mistakes by clearly differentiating these metrics when assessing equipment performance and energy efficiency to ensure accurate analysis and optimization.

Optimizing Operations: Best Practices for Managing Duty Cycle and Load Factor

Optimizing operations requires balancing duty cycle and load factor to enhance equipment efficiency and longevity. Monitoring real-time data and adjusting operational parameters ensure machinery operates within ideal load ranges, minimizing wear and energy consumption. Implementing predictive maintenance and leveraging automation further aligns duty cycle with load demand, reducing downtime and operational costs.

Duty Cycle vs Load Factor Infographic

libmatt.com

libmatt.com