Electrofuel and Power-to-Gas are innovative technologies that convert renewable electricity into fuels, with Electrofuels producing liquid fuels suitable for transportation and Power-to-Gas generating hydrogen or synthetic methane for storage and use in gas grids. Understanding the differences in application and storage capabilities helps you choose the most efficient solution for reducing carbon emissions in energy and fuel sectors.

Table of Comparison

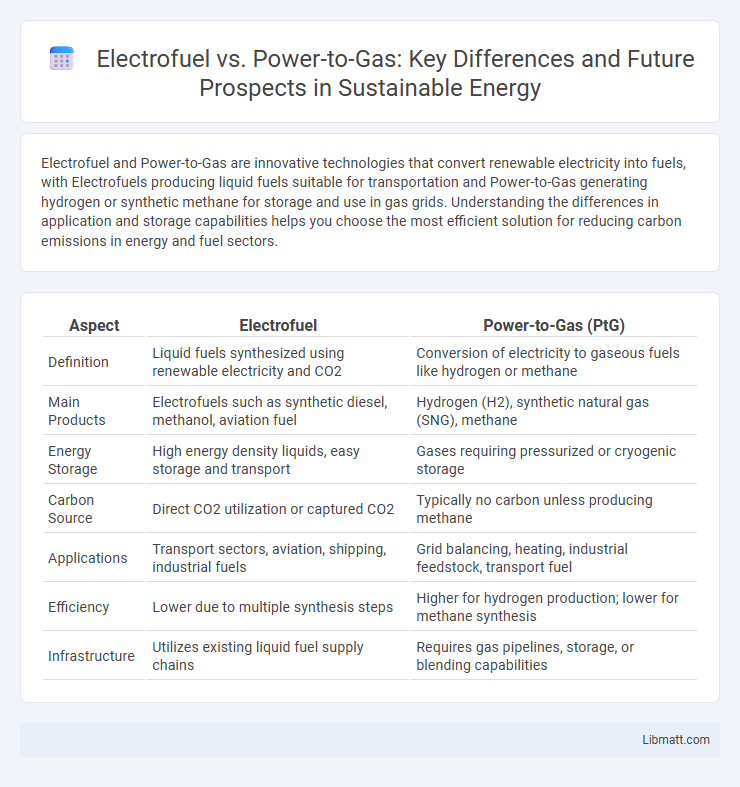

| Aspect | Electrofuel | Power-to-Gas (PtG) |

|---|---|---|

| Definition | Liquid fuels synthesized using renewable electricity and CO2 | Conversion of electricity to gaseous fuels like hydrogen or methane |

| Main Products | Electrofuels such as synthetic diesel, methanol, aviation fuel | Hydrogen (H2), synthetic natural gas (SNG), methane |

| Energy Storage | High energy density liquids, easy storage and transport | Gases requiring pressurized or cryogenic storage |

| Carbon Source | Direct CO2 utilization or captured CO2 | Typically no carbon unless producing methane |

| Applications | Transport sectors, aviation, shipping, industrial fuels | Grid balancing, heating, industrial feedstock, transport fuel |

| Efficiency | Lower due to multiple synthesis steps | Higher for hydrogen production; lower for methane synthesis |

| Infrastructure | Utilizes existing liquid fuel supply chains | Requires gas pipelines, storage, or blending capabilities |

Introduction to Electrofuel and Power-to-Gas

Electrofuel and power-to-gas are innovative energy solutions transforming renewable electricity into versatile fuels. Electrofuel encompasses synthetic liquid fuels produced by combining hydrogen generated from water electrolysis with captured carbon dioxide, offering high energy density and compatibility with existing engines. Power-to-gas primarily converts surplus renewable electricity into hydrogen or methane gas, enabling storage, grid balancing, and utilization in heating, transport, or industrial processes, empowering your transition to sustainable energy systems.

Basic Principles of Electrofuel Production

Electrofuel production relies on converting renewable electricity into liquid fuels through processes like hydrogen generation via electrolysis, followed by synthesis into hydrocarbons or alcohols, mimicking fossil fuel properties. Power-to-gas primarily produces hydrogen or methane from renewable electricity using similar electrolysis but focuses on gaseous energy carriers for storage and grid balancing. Your energy strategy can leverage electrofuels for high-density, transport-compatible fuels derived from sustainable sources, distinguishing them from gaseous alternatives in power-to-gas systems.

Understanding the Power-to-Gas Process

Power-to-gas (PtG) is a technology that converts excess renewable electricity into hydrogen or synthetic methane by splitting water through electrolysis and combining it with captured carbon dioxide. This process stores energy efficiently and enables grid balancing by injecting the gases into natural gas networks or using them as fuels. Understanding Power-to-gas helps you evaluate its role in sustainable energy systems compared to electrofuels, which directly synthesize liquid fuels from similar inputs.

Feedstocks and Energy Sources Compared

Electrofuel production relies on renewable electricity and carbon dioxide sourced from industrial emissions or direct air capture, while Power-to-gas primarily utilizes green hydrogen generated by electrolysis of water combined with carbon dioxide or surplus methane. Both technologies aim to convert renewable energy into storable fuels, but Electrofuel feedstocks emphasize capturing atmospheric CO2, whereas Power-to-gas often integrates with existing natural gas infrastructure using renewable hydrogen. Understanding these distinctions can help you evaluate the best method for integrating clean energy sources into your fuel supply strategy.

Efficiency and Energy Conversion Rates

Electrofuel production typically exhibits lower overall efficiency compared to Power-to-gas systems due to multiple energy conversion steps, including electrolysis, synthesis, and fuel formation, resulting in energy conversion rates around 35-45%. Power-to-gas, which converts electricity directly into hydrogen or methane via electrolysis and methanation, achieves higher efficiency rates of approximately 50-70%, making it more effective for large-scale energy storage and grid balancing. Understanding these energy conversion rates helps optimize Your renewable energy strategies for greater sustainability and performance.

Environmental Impact and Sustainability

Electrofuel offers a sustainable alternative by converting renewable electricity into liquid fuels, reducing carbon emissions compared to fossil fuels and enabling easier storage and transport. Power-to-gas, which produces hydrogen or synthetic methane from renewable energy, enhances grid flexibility and stores excess renewable power but faces challenges with energy density and infrastructure demands. Both technologies aim to decarbonize energy systems, yet electrofuels provide a greener solution for sectors like aviation, while power-to-gas supports grid stability and long-term energy storage.

Infrastructure Requirements and Compatibility

Electrofuel production relies heavily on existing fuel distribution networks, making it compatible with current infrastructure such as pipelines, fuel stations, and internal combustion engines. Power-to-gas requires significant upgrades to gas grid infrastructure, including compression, storage, and blending facilities, to handle hydrogen or synthetic methane safely and efficiently. Your choice between the two technologies should consider the extent of infrastructure investment and compatibility with existing energy systems to optimize implementation costs and operational integration.

Market Applications and End-Use Sectors

Electrofuel and Power-to-gas technologies serve distinct market applications, with Electrofuels primarily targeting the transportation sector, including aviation, shipping, and heavy-duty vehicles, due to their liquid fuel compatibility. Power-to-gas is more commonly applied in energy storage and grid balancing, converting surplus renewable electricity into hydrogen or synthetic methane for injection into natural gas networks or industrial use. Your choice depends on end-use sectors, where Electrofuels support decarbonizing hard-to-electrify transport, while Power-to-gas facilitates renewable integration and sector coupling in power generation and industry.

Economic Feasibility and Cost Analysis

Electrofuel production involves converting renewable electricity into liquid fuels, with costs influenced by catalysts, electrolyzer efficiency, and carbon feedstock availability, often making it more expensive than Power-to-Gas (PtG) options like hydrogen and synthetic methane. Power-to-Gas technologies typically benefit from lower capital expenditures and operational costs due to mature electrolysis and methanation processes, offering higher economic feasibility for grid balancing and long-term energy storage. Cost analyses indicate that while Electrofuels present a viable solution for sectors requiring high energy density fuels, PtG remains more economically attractive for large-scale, flexible energy storage and integration into existing gas infrastructure.

Future Prospects and Technological Innovations

Electrofuel technology, leveraging renewable electricity to synthesize liquid fuels, offers enhanced energy density and compatibility with existing fuel infrastructure, making it a promising solution for decarbonizing aviation and heavy transport sectors. Power-to-gas innovations focus on converting surplus renewable electricity into hydrogen or synthetic methane, facilitating grid balancing and seasonal energy storage with ongoing advancements in electrolyzer efficiency and carbon capture integration. Future prospects for both technologies hinge on scaling renewable energy availability, improving conversion efficiencies, and reducing production costs through breakthroughs in catalyst development and modular system design.

Electrofuel vs Power-to-gas Infographic

libmatt.com

libmatt.com