Electrostatic precipitators efficiently remove fine particles from industrial emissions using electrical charges, while baghouses rely on fabric filters to capture dust and particulate matter. Choosing between an electrostatic precipitator and a baghouse depends on your specific emission control needs, including particle size, gas volume, and maintenance considerations.

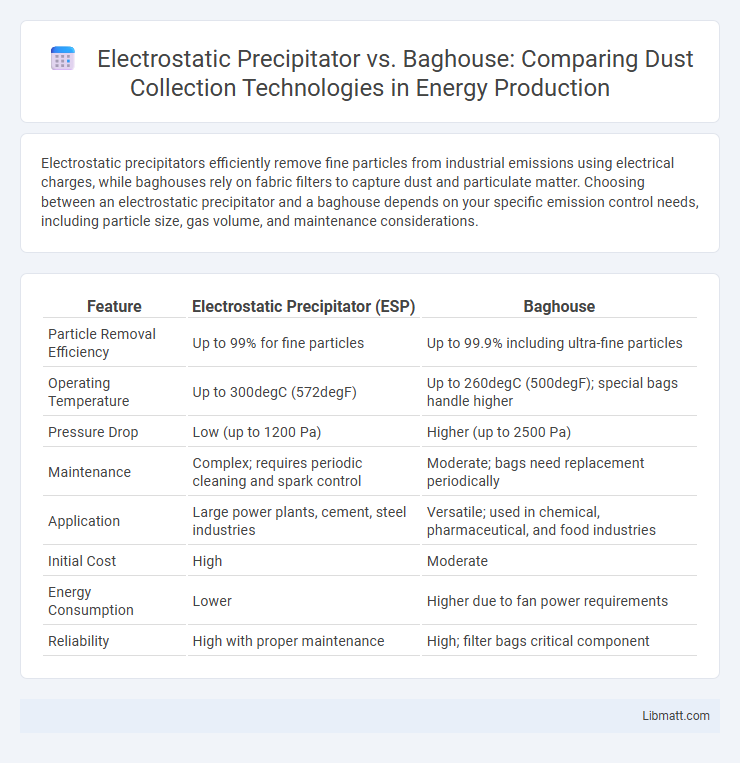

Table of Comparison

| Feature | Electrostatic Precipitator (ESP) | Baghouse |

|---|---|---|

| Particle Removal Efficiency | Up to 99% for fine particles | Up to 99.9% including ultra-fine particles |

| Operating Temperature | Up to 300degC (572degF) | Up to 260degC (500degF); special bags handle higher |

| Pressure Drop | Low (up to 1200 Pa) | Higher (up to 2500 Pa) |

| Maintenance | Complex; requires periodic cleaning and spark control | Moderate; bags need replacement periodically |

| Application | Large power plants, cement, steel industries | Versatile; used in chemical, pharmaceutical, and food industries |

| Initial Cost | High | Moderate |

| Energy Consumption | Lower | Higher due to fan power requirements |

| Reliability | High with proper maintenance | High; filter bags critical component |

Introduction to Air Pollution Control Technologies

Electrostatic precipitators use electrically charged plates to remove particles from industrial exhaust streams, effectively capturing fine particulate matter like dust and smoke. Baghouses filter air by passing it through fabric filter bags, trapping a wide range of particle sizes, including both fine and coarse dust. Your choice between these technologies depends on factors such as particle characteristics, maintenance requirements, and specific air pollution control goals.

What is an Electrostatic Precipitator (ESP)?

An Electrostatic Precipitator (ESP) is an air pollution control device that removes particulate matter from industrial exhaust streams by applying an electrostatic charge to the particles. The charged particles are then attracted to and collected on oppositely charged plates or electrodes, allowing clean air to pass through. ESPs are highly efficient for capturing fine particles and are commonly used in power plants, cement kilns, and steel mills.

How Electrostatic Precipitators Work

Electrostatic precipitators (ESPs) remove particulate matter from industrial emissions by charging particles with high-voltage electrodes, causing them to be attracted to and collected on oppositely charged plates. This process efficiently captures fine particles, including dust and smoke, from gas streams before releasing cleaned air. Your facility can benefit from ESPs by achieving high collection efficiency with low pressure drop and minimal maintenance compared to baghouses.

What is a Baghouse Dust Collector?

A baghouse dust collector is an industrial air filtration system that uses fabric filter bags to capture and remove dust particles from exhaust gases. It effectively controls particulate emissions in industries like cement, steel, and power plants by trapping dust on the surface of the bags while allowing clean air to pass through. Compared to electrostatic precipitators, baghouses provide higher collection efficiency for fine particles and handle variable gas volumes more reliably.

How Baghouse Systems Operate

Baghouse systems operate by filtering dust and particulate matter from industrial gases through large fabric filter bags, where particles are trapped on the fabric surface during air passage. These systems utilize pulse-jet, shaker, or reverse-air cleaning methods to periodically remove accumulated dust from the bags, ensuring continuous airflow. Your facility can achieve high-efficiency particulate removal, often exceeding 99%, making baghouses ideal for applications requiring fine dust capture and stringent emissions compliance.

Efficiency Comparison: Electrostatic Precipitator vs Baghouse

Electrostatic Precipitators (ESPs) achieve particulate removal efficiencies ranging from 85% to 99%, particularly excelling at capturing fine particles through electrostatic attraction. Baghouses typically offer higher efficiency, often exceeding 99.9%, by mechanically filtering particles through fabric bags, making them more effective for fine particulate matter and variable particle loads. Your choice between an ESP and a baghouse should consider targeted particle size removal and process conditions to optimize overall emission control performance.

Maintenance Requirements and Operational Costs

Electrostatic precipitators require routine cleaning of electrodes and periodic inspection of electrical components, which can increase maintenance complexity and downtime. Baghouses demand regular replacement of filter bags and frequent inspections to prevent clogging and ensure optimal airflow, resulting in higher consumable costs. Your choice impacts operational expenses significantly, with baghouses generally incurring more frequent maintenance but lower energy costs compared to the higher initial investment and electrical power consumption of electrostatic precipitators.

Application Suitability: Industries and Use Cases

Electrostatic precipitators excel in large-scale power plants and cement factories due to their efficiency in removing fine particulate matter from high-temperature flue gases. Baghouses are preferred in industries like pharmaceuticals, food processing, and metalworking where capturing a wide range of particle sizes and handling diverse dust compositions is crucial. Choosing the right technology depends on your facility's emission characteristics and operational requirements.

Environmental Impact and Emissions Performance

Electrostatic precipitators (ESPs) achieve high efficiency in removing particulate matter, particularly fine particles, reducing emissions of pollutants such as PM2.5 and PM10, thus minimizing environmental impact on air quality. Baghouse filters excel in capturing a wider range of particle sizes, including very small dust and particulate pollutants, resulting in superior overall removal efficiency and lower particulate emissions. Both systems contribute significantly to compliance with stringent air pollution regulations but differ in operational characteristics influencing maintenance, energy use, and long-term emission control benefits.

Choosing Between ESP and Baghouse: Key Considerations

Choosing between an Electrostatic Precipitator (ESP) and a Baghouse depends on factors such as particle size, gas temperature, and dust loading. ESPs excel at removing fine particulate matter and operate effectively at high temperatures but require more maintenance for high-resistivity dust. Baghouses offer high collection efficiency for a wide range of particle sizes, handle variable gas flow rates, and are better suited for sticky or moisture-laden dust.

Electrostatic Precipitator vs Baghouse Infographic

libmatt.com

libmatt.com