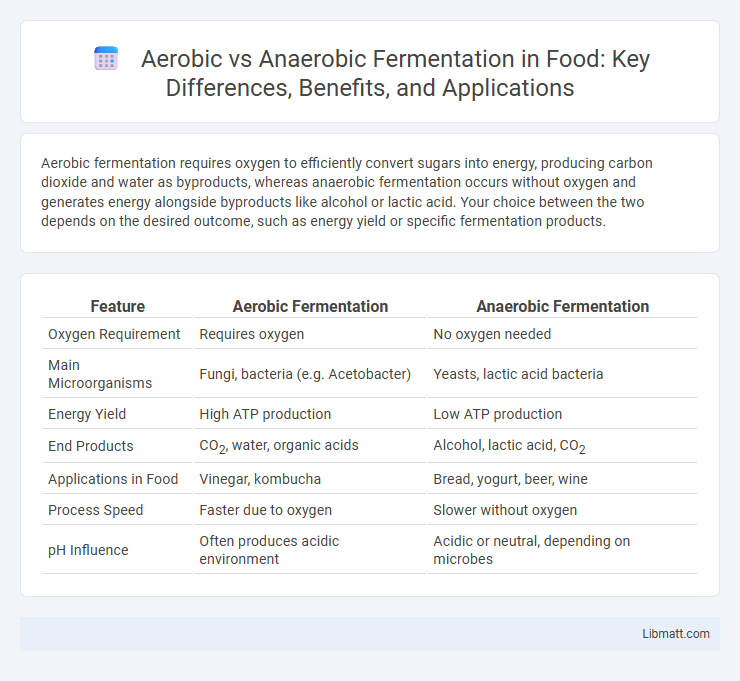

Aerobic fermentation requires oxygen to efficiently convert sugars into energy, producing carbon dioxide and water as byproducts, whereas anaerobic fermentation occurs without oxygen and generates energy alongside byproducts like alcohol or lactic acid. Your choice between the two depends on the desired outcome, such as energy yield or specific fermentation products.

Table of Comparison

| Feature | Aerobic Fermentation | Anaerobic Fermentation |

|---|---|---|

| Oxygen Requirement | Requires oxygen | No oxygen needed |

| Main Microorganisms | Fungi, bacteria (e.g. Acetobacter) | Yeasts, lactic acid bacteria |

| Energy Yield | High ATP production | Low ATP production |

| End Products | CO2, water, organic acids | Alcohol, lactic acid, CO2 |

| Applications in Food | Vinegar, kombucha | Bread, yogurt, beer, wine |

| Process Speed | Faster due to oxygen | Slower without oxygen |

| pH Influence | Often produces acidic environment | Acidic or neutral, depending on microbes |

Introduction to Fermentation Processes

Fermentation processes include aerobic fermentation, which requires oxygen to convert sugars into energy, and anaerobic fermentation, occurring without oxygen and producing energy alongside byproducts like alcohol or lactic acid. Your understanding of these mechanisms can enhance applications in biotechnology, brewing, and food preservation by optimizing yeast or bacterial activity based on oxygen availability. Key metabolic pathways differ significantly, influencing yield, efficiency, and end-product composition in various industrial and biological contexts.

Defining Aerobic Fermentation

Aerobic fermentation is a metabolic process that requires oxygen to convert sugars into energy, producing carbon dioxide and water as byproducts. It is commonly observed in yeast and certain bacteria, where oxygen presence allows more efficient ATP generation compared to anaerobic fermentation. This process supports higher energy yields, crucial for applications in biotechnology and food production industries.

Understanding Anaerobic Fermentation

Anaerobic fermentation occurs in the absence of oxygen, where microorganisms convert sugars into energy, producing byproducts like ethanol or lactic acid. This process is crucial in industries such as brewing, biofuel production, and food preservation, offering efficient energy extraction under oxygen-deprived conditions. Your understanding of anaerobic fermentation can enhance control over fermentation outcomes and optimize product quality in various biotechnological applications.

Key Differences Between Aerobic and Anaerobic Fermentation

Aerobic fermentation requires oxygen for microorganisms to convert substrates into energy, producing carbon dioxide and water as byproducts, while anaerobic fermentation occurs in the absence of oxygen, resulting in products like ethanol, lactic acid, or methane. The key difference lies in the presence or absence of oxygen, which influences the metabolic pathways and energy yield; aerobic processes generate more ATP compared to anaerobic ones. Your choice between aerobic and anaerobic fermentation impacts product formation, energy efficiency, and the types of microorganisms suitable for the process.

Biochemical Pathways in Aerobic vs Anaerobic Fermentation

Aerobic fermentation involves biochemical pathways such as the citric acid cycle and electron transport chain, which efficiently produce ATP by fully oxidizing glucose to carbon dioxide and water. Anaerobic fermentation relies primarily on glycolysis followed by fermentation pathways like lactic acid or ethanol fermentation, regenerating NAD+ without utilizing oxygen, resulting in partially oxidized end products. The key difference lies in the presence of oxygen as the terminal electron acceptor in aerobic pathways, enabling complete glucose metabolism, whereas anaerobic pathways use organic molecules as electron acceptors, yielding less energy.

Industrial Applications of Aerobic Fermentation

Industrial applications of aerobic fermentation primarily include the large-scale production of antibiotics, enzymes, and organic acids, where oxygen availability enhances microbial metabolism and product yield. This process is crucial for the manufacturing of products like citric acid, acetic acid, and vitamins, which require oxygen-dependent biosynthetic pathways. Aerobic fermentation's efficiency in biomass generation also supports the cultivation of probiotic cultures and biofuels such as bioethanol, making it indispensable in biotechnology and pharmaceutical industries.

Industrial Uses of Anaerobic Fermentation

Anaerobic fermentation plays a crucial role in industrial applications such as biofuel production, wastewater treatment, and the synthesis of biochemicals like ethanol and organic acids. This process efficiently converts organic materials into valuable products without the need for oxygen, enabling cost-effective and sustainable manufacturing methods. Your industry can leverage anaerobic fermentation to enhance energy recovery and reduce environmental impact through innovative bioprocesses.

Advantages and Disadvantages of Each Fermentation Type

Aerobic fermentation offers higher energy yield by utilizing oxygen, producing more ATP per glucose molecule, which supports faster microbial growth and efficiency in processes like bioremediation. However, it requires continuous oxygen supply, increasing operational costs and risks of oxidative stress on cells. Anaerobic fermentation operates in oxygen-free environments, enabling production of valuable byproducts like ethanol, lactic acid, and biogas, ideal for biofuel and food industries, but it generates less energy and often slower growth rates, limiting biomass accumulation.

Factors Influencing Fermentation Outcomes

Temperature, pH levels, and substrate type significantly influence both aerobic and anaerobic fermentation outcomes, affecting microbial activity and product yield. Oxygen availability distinguishes the two processes: aerobic fermentation requires oxygen for efficient energy production, while anaerobic fermentation occurs in its absence, leading to different metabolic byproducts. Managing these factors ensures optimal fermentation conditions, enhancing your desired product quality and consistency.

Future Trends in Fermentation Technologies

Future trends in fermentation technologies emphasize the integration of advanced bioreactor designs and synthetic biology to enhance both aerobic and anaerobic fermentation yields. Innovations such as real-time metabolic monitoring and automated process control are expected to optimize microbial activity under oxygen-rich and oxygen-deprived conditions. Emerging approaches include the development of genetically engineered microorganisms tailored for efficient substrate conversion, reducing production costs and environmental impact in pharmaceutical, biofuel, and food industries.

Aerobic Fermentation vs Anaerobic Fermentation Infographic

libmatt.com

libmatt.com