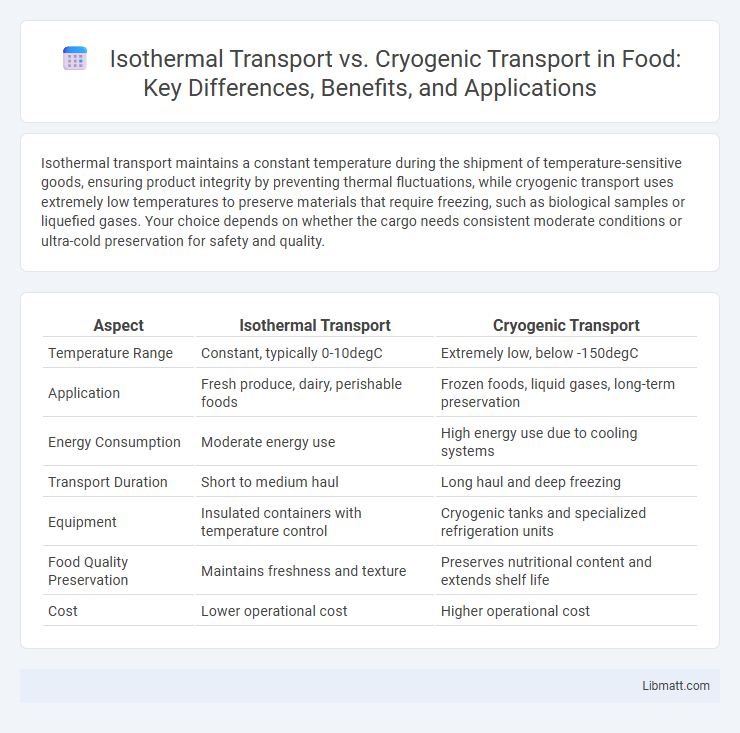

Isothermal transport maintains a constant temperature during the shipment of temperature-sensitive goods, ensuring product integrity by preventing thermal fluctuations, while cryogenic transport uses extremely low temperatures to preserve materials that require freezing, such as biological samples or liquefied gases. Your choice depends on whether the cargo needs consistent moderate conditions or ultra-cold preservation for safety and quality.

Table of Comparison

| Aspect | Isothermal Transport | Cryogenic Transport |

|---|---|---|

| Temperature Range | Constant, typically 0-10degC | Extremely low, below -150degC |

| Application | Fresh produce, dairy, perishable foods | Frozen foods, liquid gases, long-term preservation |

| Energy Consumption | Moderate energy use | High energy use due to cooling systems |

| Transport Duration | Short to medium haul | Long haul and deep freezing |

| Equipment | Insulated containers with temperature control | Cryogenic tanks and specialized refrigeration units |

| Food Quality Preservation | Maintains freshness and texture | Preserves nutritional content and extends shelf life |

| Cost | Lower operational cost | Higher operational cost |

Introduction to Temperature-Controlled Transport

Temperature-controlled transport ensures the integrity of sensitive goods by maintaining consistent thermal conditions throughout the journey. Isothermal transport uses insulated containers to keep products at a stable temperature without active cooling, suitable for short to medium durations. Cryogenic transport employs ultra-low temperatures using liquid nitrogen or other cryogens to preserve biological samples and pharmaceuticals over extended periods.

Understanding Isothermal Transport

Isothermal transport ensures the stable maintenance of a material's temperature during transit, preventing thermal fluctuations that could compromise product integrity. This method is essential for pharmaceuticals, chemicals, and perishable goods requiring strict temperature control without the use of extreme cooling. Your choice of isothermal transport guarantees consistent conditions, safeguarding quality in comparison to cryogenic transport, which relies on ultra-low temperatures.

Overview of Cryogenic Transport

Cryogenic transport involves the movement of materials at extremely low temperatures, typically below -150degC, to preserve their physical and chemical properties. It is essential for substances such as liquefied gases (e.g., liquid nitrogen, oxygen, and helium) and biological samples requiring strict temperature control. Advanced insulation techniques and specialized containers like vacuum-insulated cryogenic tanks enable safe, efficient transport while minimizing thermal losses and preventing phase changes.

Key Differences Between Isothermal and Cryogenic Methods

Isothermal transport maintains a stable temperature to prevent phase changes, ideal for sensitive biological samples, while cryogenic transport involves extremely low temperatures to preserve materials like vaccines or biological tissues by freezing. The key difference lies in temperature control; isothermal methods avoid freezing, whereas cryogenic methods rely on it to halt biological activity and degradation. Your choice depends on whether maintaining a consistent non-freezing temperature or deep freezing is critical for preserving the cargo's viability and integrity.

Applications of Isothermal Transport

Isothermal transport is widely used in industries requiring precise temperature control, such as pharmaceuticals, food, and chemical sectors, to ensure product stability during transit. This method maintains a constant temperature, preventing degradation of temperature-sensitive goods, which is crucial for vaccines, perishable foods, and specialized chemicals. Your choice of isothermal transport guarantees optimal conditions, preserving product integrity from origin to destination.

Use Cases for Cryogenic Transport

Cryogenic transport is essential for industries requiring the movement of liquefied gases such as oxygen, nitrogen, and liquid natural gas (LNG) at extremely low temperatures to maintain their liquid state. It is widely used in medical applications for transporting biological samples and in aerospace for fueling rockets with super-cooled propellants. The energy sector relies heavily on cryogenic transport to ensure safe and efficient delivery of LNG to power plants and distribution centers.

Equipment and Technology Used

Isothermal transport relies on advanced insulation materials and phase change thermal storage systems to maintain a stable temperature without active cooling, using vacuum panels or nanogel insulation to minimize heat exchange. Cryogenic transport employs specialized cryogenic tanks equipped with vacuum jackets, multilayer insulation, and pressure-relief valves to safely contain and transport liquefied gases at extremely low temperatures, often below -150degC. Both technologies integrate sensors and monitoring systems to ensure precise temperature control and prevent contamination or loss of product integrity during transit.

Safety and Regulatory Considerations

Isothermal transport maintains stable temperatures without extreme cooling, reducing risks of pressure fluctuations and thermal stress, which simplifies compliance with safety regulations compared to cryogenic transport. Cryogenic transport involves handling ultra-low temperatures that require specialized insulated containers and strict adherence to hazardous material regulations due to risks like frostbite, oxygen displacement, and container rupture. Ensuring your cargo meets regulatory standards involves selecting the appropriate transport method based on temperature sensitivity and safety protocols mandated by agencies such as the DOT and OSHA.

Cost Implications and Efficiency

Isothermal transport maintains stable temperatures using advanced insulation and phase change materials, resulting in moderate operational costs and energy efficiency for short to medium distances. Cryogenic transport requires ultra-low temperatures achieved through liquid nitrogen or helium, incurring higher costs due to specialized equipment and continuous cooling needs, but it excels in preserving temperature-sensitive materials over long distances. Efficiency in isothermal transport is higher for frequent, shorter trips, while cryogenic systems optimize performance for extended duration and maximum temperature stability.

Choosing the Right Method for Your Needs

Selecting between isothermal and cryogenic transport depends on the thermal sensitivity and required temperature range of your cargo. Isothermal transport maintains a stable, moderate temperature ideal for products that cannot tolerate freezing but need cooling, while cryogenic transport uses extremely low temperatures for materials like liquefied gases and biological samples requiring deep freeze preservation. Evaluating factors such as transport duration, insulation type, and temperature control precision ensures the most effective preservation and safety of your goods.

Isothermal Transport vs Cryogenic Transport Infographic

libmatt.com

libmatt.com