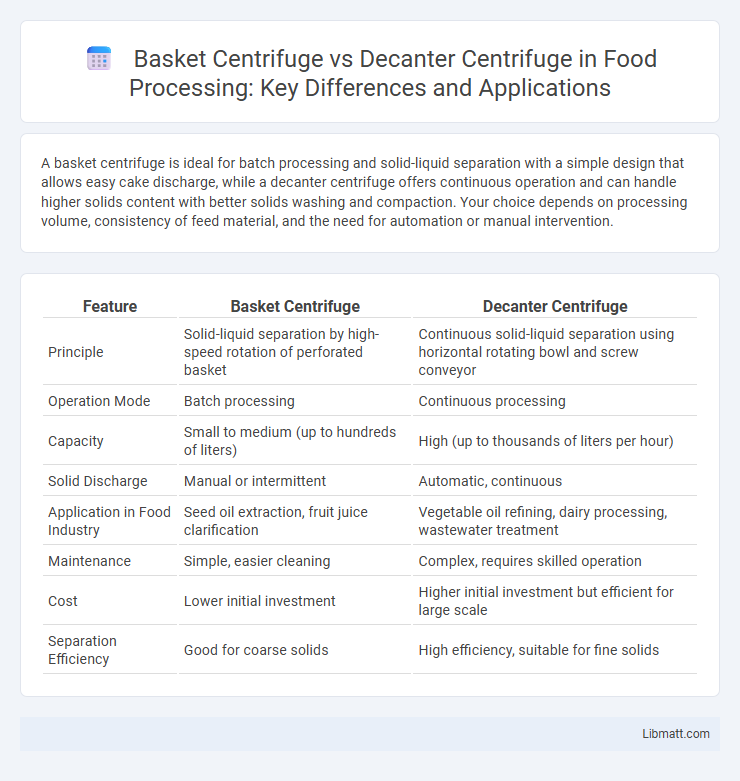

A basket centrifuge is ideal for batch processing and solid-liquid separation with a simple design that allows easy cake discharge, while a decanter centrifuge offers continuous operation and can handle higher solids content with better solids washing and compaction. Your choice depends on processing volume, consistency of feed material, and the need for automation or manual intervention.

Table of Comparison

| Feature | Basket Centrifuge | Decanter Centrifuge |

|---|---|---|

| Principle | Solid-liquid separation by high-speed rotation of perforated basket | Continuous solid-liquid separation using horizontal rotating bowl and screw conveyor |

| Operation Mode | Batch processing | Continuous processing |

| Capacity | Small to medium (up to hundreds of liters) | High (up to thousands of liters per hour) |

| Solid Discharge | Manual or intermittent | Automatic, continuous |

| Application in Food Industry | Seed oil extraction, fruit juice clarification | Vegetable oil refining, dairy processing, wastewater treatment |

| Maintenance | Simple, easier cleaning | Complex, requires skilled operation |

| Cost | Lower initial investment | Higher initial investment but efficient for large scale |

| Separation Efficiency | Good for coarse solids | High efficiency, suitable for fine solids |

Introduction to Basket and Decanter Centrifuges

Basket centrifuges utilize a perforated basket that spins at high speeds to separate solids from liquids based on sedimentation, making them ideal for batch processing of materials with high solid content. Decanter centrifuges feature a rotating bowl and a screw conveyor that continuously separate and remove solids from liquids, optimizing efficiency for continuous operations in industries such as wastewater treatment and chemical processing. Your choice between these centrifuge types depends on processing requirements, including feed characteristics, desired throughput, and maintenance considerations.

Working Principles of Basket Centrifuges

Basket centrifuges operate by spinning a perforated cylindrical basket at high speeds, using centrifugal force to separate solid particles from liquids as the slurry moves through the basket walls. The centrifugal acceleration drives solids outward, where they accumulate on the basket surface while clarified liquid passes through the perforations. This solid-liquid separation is efficient for batch processing and is commonly used in pharmaceutical and chemical industries.

Decanter Centrifuge: Operation and Mechanism

Decanter centrifuges operate using a horizontal rotating bowl and a screw conveyor inside, which work together to separate solids from liquids by centrifugal force. The rotating bowl spins at high speeds, causing denser solids to settle against the bowl wall, while the screw conveyor slowly moves the settled solids toward the discharge end. Your understanding of the decanter centrifuge's mechanism helps optimize processes in industries like wastewater treatment, chemical manufacturing, and food processing.

Key Differences Between Basket and Decanter Centrifuges

Basket centrifuges separate solids from liquids by spinning a perforated basket at high speeds, allowing liquids to pass through while solids remain inside, ideal for batch processing of high-solid content materials. Decanter centrifuges operate continuously, using a rotating bowl and screw conveyor to separate large volumes of mixtures with lower solid concentrations, making them suitable for industrial-scale liquid-solid separation. Your choice depends on specific processing needs such as throughput, solid concentration, and the nature of the feed material.

Applications of Basket Centrifuges

Basket centrifuges excel in applications requiring the separation of solids from liquids with moderate solid content, such as chemical processing, wastewater treatment, and pharmaceuticals. They efficiently handle granular or crystalline solids in slurry form, commonly used for cake washing and dewatering in mining and food industries. Their design supports batch operations with high clarity of the separated liquid, making them ideal for processes needing frequent solid discharge and minimal liquid carryover.

Decanter Centrifuge: Industry Uses and Fields

Decanter centrifuges are extensively used in industries such as wastewater treatment, chemical processing, food and beverage production, and oil and gas for efficient solid-liquid separation. They handle large volumes of slurry with varying solid concentrations, making them essential for sludge dewatering, biomass recovery, and oil extraction processes. Their ability to continuously separate solids from liquids under high throughput conditions distinguishes them from basket centrifuges, which are typically suited for smaller batch separations.

Advantages of Basket Centrifuges

Basket centrifuges offer superior solid-liquid separation efficiency due to their high rotational speed and effective cake washing capabilities. They provide easy maintenance with simple design and fewer moving parts, reducing downtime and operational costs. Their compact size and ability to handle variable feed rates make them ideal for applications requiring rapid batch processing and precise solid recovery.

Decanter Centrifuge: Benefits and Limitations

Decanter centrifuges offer continuous solid-liquid separation with high throughput and efficient handling of large volumes, making them ideal for wastewater treatment and industrial sludge dewatering. Their limitations include higher energy consumption and complexity in maintenance compared to basket centrifuges, as well as less effective separation of fine particles. Despite these constraints, decanter centrifuges provide superior automation capabilities and adaptability to varying feed compositions.

Factors to Consider When Choosing Between Basket and Decanter Centrifuges

Consider the material properties and separation requirements when choosing between basket and decanter centrifuges. Basket centrifuges excel in separating solids from liquids with relatively low solid content and are suitable for batch processing, while decanter centrifuges handle higher solid concentrations with continuous operation. Your decision should also account for maintenance needs, operational costs, and the specific application environment to ensure optimal performance and efficiency.

Conclusion: Which Centrifuge Suits Your Process?

Basket centrifuges excel in applications requiring solid-liquid separation with high dryness due to their rapid spin and effective cake washing, making them ideal for pharmaceuticals and chemical processes. Decanter centrifuges offer continuous operation and handle large volumes of slurry with varying solid concentrations, suitable for wastewater treatment and oil processing industries. Your choice depends on the required throughput, separation efficiency, and the nature of the feed material in your specific process.

basket centrifuge vs decanter centrifuge Infographic

libmatt.com

libmatt.com