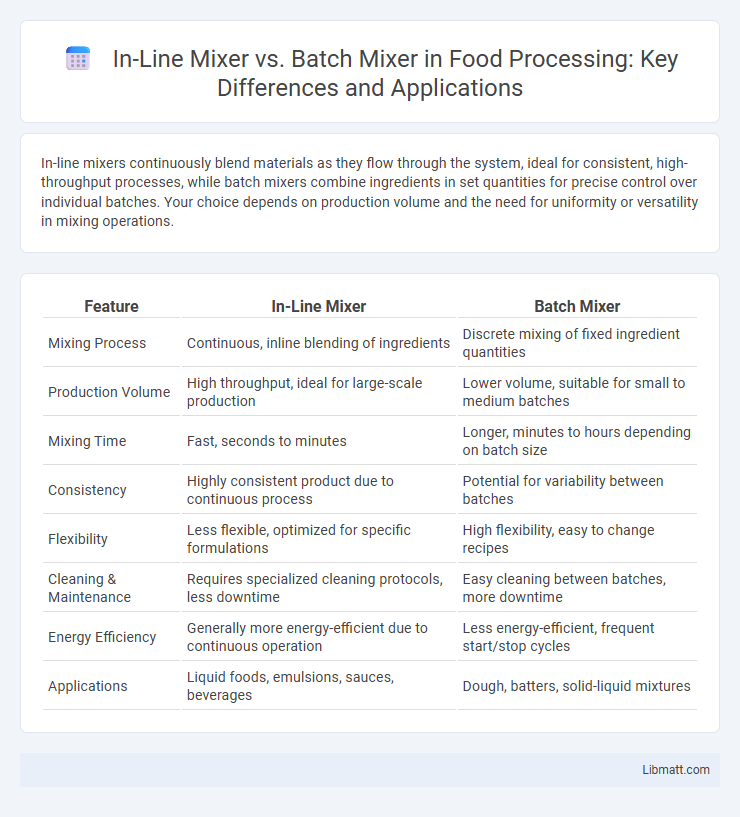

In-line mixers continuously blend materials as they flow through the system, ideal for consistent, high-throughput processes, while batch mixers combine ingredients in set quantities for precise control over individual batches. Your choice depends on production volume and the need for uniformity or versatility in mixing operations.

Table of Comparison

| Feature | In-Line Mixer | Batch Mixer |

|---|---|---|

| Mixing Process | Continuous, inline blending of ingredients | Discrete mixing of fixed ingredient quantities |

| Production Volume | High throughput, ideal for large-scale production | Lower volume, suitable for small to medium batches |

| Mixing Time | Fast, seconds to minutes | Longer, minutes to hours depending on batch size |

| Consistency | Highly consistent product due to continuous process | Potential for variability between batches |

| Flexibility | Less flexible, optimized for specific formulations | High flexibility, easy to change recipes |

| Cleaning & Maintenance | Requires specialized cleaning protocols, less downtime | Easy cleaning between batches, more downtime |

| Energy Efficiency | Generally more energy-efficient due to continuous operation | Less energy-efficient, frequent start/stop cycles |

| Applications | Liquid foods, emulsions, sauces, beverages | Dough, batters, solid-liquid mixtures |

Introduction to In-line and Batch Mixers

In-line mixers continuously blend materials by passing them through a fixed chamber, ensuring consistent product quality and reducing processing time compared to batch mixers, which mix ingredients in discrete, separate quantities. Batch mixers offer enhanced control over individual mix cycles, making them ideal for customized formulations or smaller production runs. Understanding your production needs helps determine whether an in-line mixer's efficiency or a batch mixer's flexibility better suits your process.

How In-line Mixers Work

In-line mixers work by continuously blending fluids directly within the pipeline using high-shear mixing elements, ensuring uniform consistency and rapid dispersion of ingredients. This process eliminates the need for separate mixing vessels, reducing processing time and minimizing contamination risks. Your production efficiency can significantly improve with in-line mixing due to its seamless integration into automated systems.

How Batch Mixers Operate

Batch mixers operate by combining ingredients in discrete, predefined quantities within a closed mixing chamber, allowing precise control over mixing time and speed to ensure uniformity. These mixers are ideal for small to medium production runs where flexibility and thorough blending of complex formulas are required. Your choice of a batch mixer supports consistent product quality by enabling tailored mixing cycles for each batch.

Key Differences Between In-line and Batch Mixing

In-line mixers provide continuous processing by blending materials as they flow through the system, ensuring consistent product quality and efficient use of space. Batch mixers handle fixed volumes in separate cycles, offering flexibility for varying formulations and easier control over mixing time. Your choice depends on production volume needs, with in-line mixers optimizing large-scale, continuous operations while batch mixers suit smaller, more customizable batches.

Advantages of In-line Mixing Systems

In-line mixers offer continuous processing, which significantly reduces production time and increases efficiency compared to batch mixers. They provide consistent and uniform mixing quality by maintaining constant flow and precise control over mixing parameters, minimizing variability. The compact design of in-line mixing systems also saves floor space and reduces cleaning time, enhancing overall operational productivity.

Benefits of Batch Mixing Processes

Batch mixing processes provide precise control over ingredient proportions, ensuring consistent quality and uniformity in each production run. Your ability to customize formulations flexibly meets varied product requirements, enhancing versatility across different applications. This method also facilitates easier cleaning and maintenance between batches, reducing contamination risk and improving overall product safety.

Applications Best Suited for In-line Mixers

In-line mixers excel in continuous blending processes where uniformity and speed are critical, making them ideal for applications in pharmaceuticals, food and beverage, and chemical production. These mixers efficiently handle liquids with varying viscosities, ensuring consistent texture and composition without the need for large mixing vessels. You benefit from reduced processing times and space savings, especially in industries requiring high throughput and precise ingredient dispersion.

Industries Where Batch Mixers Excel

Batch mixers excel in industries requiring high flexibility and precise control over small production runs, such as pharmaceuticals, cosmetics, and specialty chemicals. These mixers allow for customizable formulations and thorough quality checks, ensuring consistent product integrity. Your production benefits from the ability to adjust recipes quickly to meet varying demands or regulatory requirements.

Factors to Consider When Choosing a Mixing Solution

When choosing between an in-line mixer and a batch mixer, factors such as production volume, mixing time, and product consistency are critical. In-line mixers excel in continuous processing with high throughput and uniform results, while batch mixers offer flexibility for small batches and varied formulations. Considerations like space availability, cleaning requirements, and integration with existing systems also influence the optimal mixing solution choice.

Conclusion: Selecting the Right Mixer for Your Needs

Choosing the right mixer depends on your production volume and process requirements; in-line mixers offer continuous processing ideal for high-volume, consistent blends, while batch mixers provide flexibility for smaller, varied batches. Your decision should consider factors like mixing time, product homogeneity, and scalability. Assessing these criteria ensures efficient operation and optimal product quality for your specific applications.

in-line mixer vs batch mixer Infographic

libmatt.com

libmatt.com