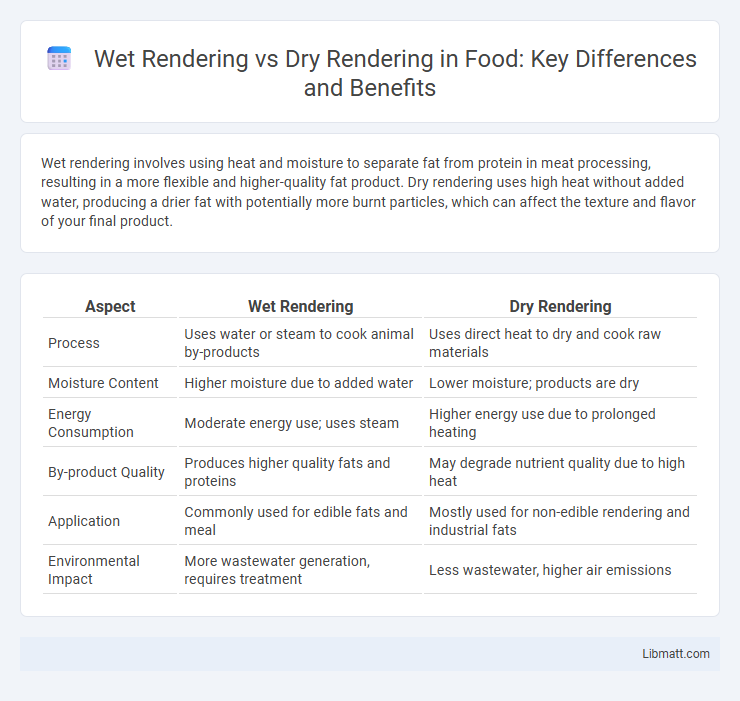

Wet rendering involves using heat and moisture to separate fat from protein in meat processing, resulting in a more flexible and higher-quality fat product. Dry rendering uses high heat without added water, producing a drier fat with potentially more burnt particles, which can affect the texture and flavor of your final product.

Table of Comparison

| Aspect | Wet Rendering | Dry Rendering |

|---|---|---|

| Process | Uses water or steam to cook animal by-products | Uses direct heat to dry and cook raw materials |

| Moisture Content | Higher moisture due to added water | Lower moisture; products are dry |

| Energy Consumption | Moderate energy use; uses steam | Higher energy use due to prolonged heating |

| By-product Quality | Produces higher quality fats and proteins | May degrade nutrient quality due to high heat |

| Application | Commonly used for edible fats and meal | Mostly used for non-edible rendering and industrial fats |

| Environmental Impact | More wastewater generation, requires treatment | Less wastewater, higher air emissions |

Introduction to Wet Rendering and Dry Rendering

Wet rendering involves processing animal fat by boiling it with water to separate the fat from proteins and moisture, resulting in higher-quality tallow with reduced impurities. Dry rendering, on the other hand, uses direct heat to melt fat without added water, typically producing lower-quality fat with more impurities and requiring additional refining steps. Both methods are integral in the rendering industry for converting animal by-products into usable fats, but wet rendering is favored for producing food-grade fats, while dry rendering is more common in industrial applications.

Key Differences Between Wet and Dry Rendering

Wet rendering involves applying a mixture of cement, sand, and water directly onto surfaces, allowing for smooth, adhesive finishes that enhance wall durability and weather resistance. Dry rendering uses premixed materials or powder that are mixed with water on-site, offering quicker application and reducing waste but potentially requiring additional finishing for uniform texture. Key differences include the method of preparation, application speed, texture consistency, and the level of surface adherence, influencing the choice based on project requirements and environmental conditions.

Advantages of Wet Rendering

Wet rendering preserves more natural fats and flavors by using water or steam during the process, resulting in higher-quality lard or tallow. This method reduces the risk of burning and off-flavors often associated with dry rendering, enhancing the taste and texture of the final product. Additionally, wet rendering yields cleaner fat with fewer impurities, making it ideal for culinary and cosmetic applications.

Advantages of Dry Rendering

Dry rendering offers significant advantages such as faster application and reduced drying time compared to wet rendering, making it ideal for projects with tight schedules. It provides enhanced durability and resistance to cracking due to pre-mixed factory-controlled materials, ensuring consistent quality. The dry mix also allows greater flexibility in texture and finish, catering to diverse architectural designs and exterior requirements.

Disadvantages of Wet Rendering

Wet rendering presents disadvantages such as high water consumption and increased wastewater production, leading to environmental concerns and higher treatment costs. The process requires significant energy input for drying and handling the slurry, which can reduce overall efficiency. Your facility may also face challenges with odor control and longer processing times compared to dry rendering techniques.

Disadvantages of Dry Rendering

Dry rendering often results in a rougher finish and lower adhesion compared to wet rendering, making it less durable in harsh weather conditions. This method also tends to generate more dust during application, posing health risks and requiring careful site management. Your choice of rendering should consider these limitations, especially in environments demanding high moisture resistance and smooth surfaces.

Ideal Applications for Wet Rendering

Wet rendering is ideal for applications requiring smooth, even surfaces such as exterior building facades and walls exposed to varying weather conditions. This technique provides excellent protection against moisture and improves insulation, making it suitable for residential and commercial buildings in humid or rainy climates. Your project benefits from wet rendering when durability and enhanced weather resistance are top priorities.

Best Uses for Dry Rendering

Dry rendering is best suited for areas requiring quick application and minimal curing time, such as patch repairs and rough surfaces. Its breathable nature makes it ideal for external wall facades exposed to moisture, preventing trapped water and reducing the risk of dampness. Your choice of dry rendering ensures durability and flexibility in environments where rapid drying and ease of use are essential.

Cost Comparison: Wet Rendering vs Dry Rendering

Wet rendering typically involves higher initial costs due to materials like cement and sand, plus labor for mixing and application, but it offers better durability and weather resistance. Dry rendering tends to be more cost-effective upfront as it uses premixed dry plasters and requires less labor time, making it suitable for quick repairs or budget projects. Your choice depends on long-term maintenance budgets and performance needs in different environmental conditions.

Choosing the Right Rendering Method

Choosing the right rendering method depends on project requirements such as budget, surface durability, and application speed. Wet rendering offers a smooth, weather-resistant finish ideal for exterior walls but requires longer drying times and skilled labor. Dry rendering, while faster and easier to apply, suits interior walls or low-moisture environments but may lack the long-term durability of wet render.

wet rendering vs dry rendering Infographic

libmatt.com

libmatt.com