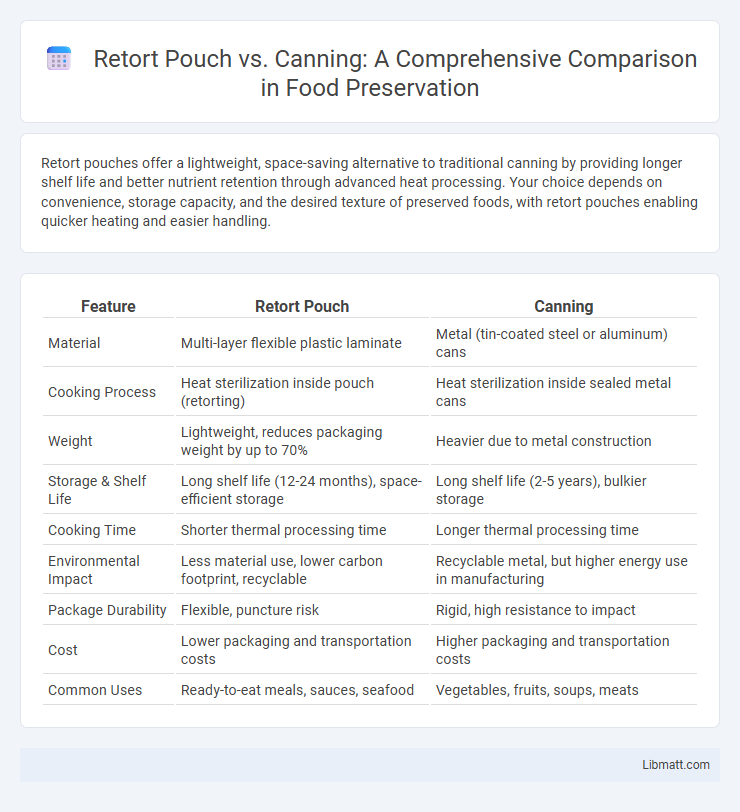

Retort pouches offer a lightweight, space-saving alternative to traditional canning by providing longer shelf life and better nutrient retention through advanced heat processing. Your choice depends on convenience, storage capacity, and the desired texture of preserved foods, with retort pouches enabling quicker heating and easier handling.

Table of Comparison

| Feature | Retort Pouch | Canning |

|---|---|---|

| Material | Multi-layer flexible plastic laminate | Metal (tin-coated steel or aluminum) cans |

| Cooking Process | Heat sterilization inside pouch (retorting) | Heat sterilization inside sealed metal cans |

| Weight | Lightweight, reduces packaging weight by up to 70% | Heavier due to metal construction |

| Storage & Shelf Life | Long shelf life (12-24 months), space-efficient storage | Long shelf life (2-5 years), bulkier storage |

| Cooking Time | Shorter thermal processing time | Longer thermal processing time |

| Environmental Impact | Less material use, lower carbon footprint, recyclable | Recyclable metal, but higher energy use in manufacturing |

| Package Durability | Flexible, puncture risk | Rigid, high resistance to impact |

| Cost | Lower packaging and transportation costs | Higher packaging and transportation costs |

| Common Uses | Ready-to-eat meals, sauces, seafood | Vegetables, fruits, soups, meats |

Introduction to Retort Pouch and Canning

Retort pouch technology utilizes flexible laminated plastic pouches designed for high-temperature sterilization, offering lightweight and space-efficient packaging for ready-to-eat meals. Canning involves sealing food in rigid metal or glass containers, followed by thermal processing to ensure long shelf life and microbial safety. Both methods ensure food preservation but differ significantly in packaging materials, weight, and processing efficiency.

Historical Overview of Food Preservation Methods

Retort pouches emerged in the late 20th century as a flexible alternative to traditional canning, which dates back to the early 19th century with Nicolas Appert's pioneering method of heat sterilization in sealed containers. While canning revolutionized industrial food preservation by allowing long-term storage without refrigeration, retort pouches introduced advancements in packaging technology, reducing weight and cooking times while maintaining shelf stability. Both methods rely on thermal processing to eliminate microbes, but retort pouches utilize laminated films that enable faster heat transfer and improved convenience in modern food distribution.

How Retort Pouch Packaging Works

Retort pouch packaging uses a laminated flexible film made from polyester, aluminum foil, and polypropylene to create a lightweight, durable container that can withstand high-temperature sterilization. The sealed pouch is filled with food and subjected to steam or pressure cooking in a retort sterilizer, which eliminates bacteria and preserves the contents without the need for preservatives. This method offers faster processing times and better retention of nutrients and flavors compared to traditional canning, which uses heavy metal cans and longer heat exposure.

Canning Process Explained

The canning process involves placing food in jars or cans, then heating them to a temperature that destroys harmful microorganisms and seals the containers to prevent contamination. This method ensures long shelf life and preserves the nutritional content of foods by creating a vacuum seal during cooling. Your choice between retort pouches and traditional canning depends on factors like packaging weight, storage space, and processing time.

Key Differences Between Retort Pouch and Canning

Retort pouches and canning both provide long-term food preservation, but retort pouches use flexible laminated materials allowing faster heat penetration, resulting in shorter processing times and better nutrient retention compared to traditional metal cans. Retort packaging is lightweight and space-saving, reducing transportation and storage costs while offering excellent barrier properties against oxygen and moisture. Your choice depends on factors like product type, shelf life, and consumer convenience, with retort pouches ideal for ready-to-eat meals and canning preferred for robust shelf-stable products like vegetables and sauces.

Shelf Life and Food Safety Comparison

Retort pouches typically offer shelf lives ranging from 12 to 24 months due to their high-barrier materials and ability to withstand thermal processing, while traditional canning can preserve food safely for up to 2-5 years depending on product type and storage conditions. Both methods undergo retort sterilization, ensuring commercial sterility and inhibition of pathogens like Clostridium botulinum, but retort pouches often result in faster heat penetration, improving nutrient retention and reducing thermal degradation. Food safety regulations from FDA and USDA apply equally to both packaging types, mandating strict process validation to guarantee extended shelf stability without compromising microbial safety.

Environmental Impact: Retort Pouch vs Canning

Retort pouches offer a significant environmental advantage over traditional canning due to their lighter weight and reduced material usage, resulting in lower transportation emissions and less waste in landfills. Canning typically involves heavy metal containers that require more energy to produce and recycle, increasing the overall carbon footprint. By choosing retort pouches, your packaging solutions can contribute to more sustainable practices and reduced environmental impact.

Cost Analysis for Manufacturers and Consumers

Retort pouches offer manufacturers lower processing and transportation costs due to reduced energy consumption and lighter packaging compared to traditional canning. Consumers benefit from retort pouches through potentially lower retail prices and enhanced convenience, as these pouches are more portable and easier to store. Your overall cost savings come from both the reduced manufacturing overhead and the efficient distribution logistics associated with retort pouch packaging.

Consumer Preferences and Market Trends

Consumer preferences are shifting towards retort pouch packaging due to its lightweight, convenience, and extended shelf life compared to traditional canning. Market trends indicate a growing demand for eco-friendly and portable food packaging, with retort pouches offering reduced environmental impact and easier storage. Your choice between retort pouch and canning should consider these evolving preferences for sustainability and convenience.

Future of Food Packaging Technologies

Retort pouch technology offers advantages over traditional canning by providing lightweight, flexible, and energy-efficient packaging that extends shelf life while maintaining food quality. Emerging innovations in retort pouch materials emphasize sustainable, recyclable solutions that reduce environmental impact compared to metal cans. Advancements in barrier films, sterilization techniques, and smart packaging integration position retort pouches as a leading solution in the future of food packaging technologies.

Retort Pouch vs Canning Infographic

libmatt.com

libmatt.com