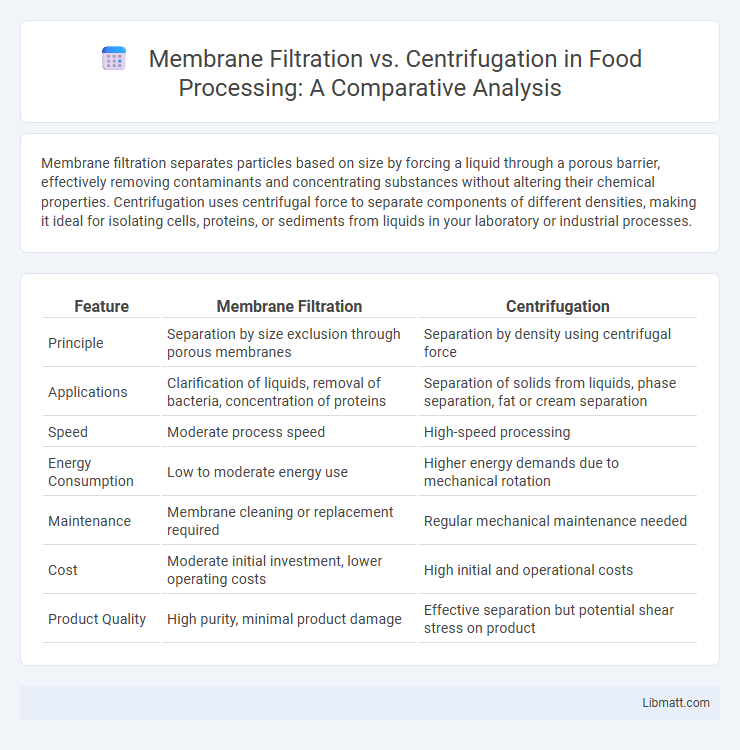

Membrane filtration separates particles based on size by forcing a liquid through a porous barrier, effectively removing contaminants and concentrating substances without altering their chemical properties. Centrifugation uses centrifugal force to separate components of different densities, making it ideal for isolating cells, proteins, or sediments from liquids in your laboratory or industrial processes.

Table of Comparison

| Feature | Membrane Filtration | Centrifugation |

|---|---|---|

| Principle | Separation by size exclusion through porous membranes | Separation by density using centrifugal force |

| Applications | Clarification of liquids, removal of bacteria, concentration of proteins | Separation of solids from liquids, phase separation, fat or cream separation |

| Speed | Moderate process speed | High-speed processing |

| Energy Consumption | Low to moderate energy use | Higher energy demands due to mechanical rotation |

| Maintenance | Membrane cleaning or replacement required | Regular mechanical maintenance needed |

| Cost | Moderate initial investment, lower operating costs | High initial and operational costs |

| Product Quality | High purity, minimal product damage | Effective separation but potential shear stress on product |

Introduction to Membrane Filtration and Centrifugation

Membrane filtration uses semi-permeable membranes to separate particles based on size and molecular weight, offering high precision in removing contaminants from liquids. Centrifugation relies on centrifugal force to separate components of a mixture according to their density differences, commonly employed in biochemical and industrial processes. Both techniques are essential for purification and separation in pharmaceuticals, water treatment, and food processing industries.

Principles of Membrane Filtration

Membrane filtration operates on the principle of size exclusion, where a semipermeable membrane allows smaller molecules or particles to pass while retaining larger contaminants. This method effectively separates substances based on molecular dimensions, employing techniques such as microfiltration, ultrafiltration, nanofiltration, or reverse osmosis. The selective permeability of membranes ensures high efficiency in removing particulates, bacteria, and even dissolved solids from liquids.

Fundamentals of Centrifugation

Centrifugation separates particles based on density by spinning samples at high speeds, creating a strong centrifugal force that moves heavier components toward the vessel's outer edge. This process is essential for isolating cells, organelles, and macromolecules in various scientific and industrial applications. When comparing to membrane filtration, centrifugation offers rapid separation without the risk of filter clogging, making it ideal for processing complex mixtures in your laboratory or production facility.

Key Differences Between Membrane Filtration and Centrifugation

Membrane filtration separates particles based on size exclusion through a porous barrier, making it ideal for clarifying liquids and removing microorganisms. Centrifugation relies on centrifugal force to separate components by density, effectively concentrating cells or separating phases in heterogeneous mixtures. Membrane filtration offers continuous operation with precise pore-size control, while centrifugation provides rapid phase separation but may cause shear damage to sensitive materials.

Applications of Membrane Filtration

Membrane filtration is widely used in water purification, wastewater treatment, and food and beverage processing to separate contaminants and ensure product quality. It effectively removes suspended solids, bacteria, and viruses, making it essential for producing potable water and sterile pharmaceuticals. Your processes can benefit from membrane filtration's precision in separating particles based on size and molecular weight without requiring high energy input.

Applications of Centrifugation

Centrifugation is widely applied in biotechnology, pharmaceuticals, and wastewater treatment for separating particles based on density differences, enabling efficient isolation of cells, proteins, and other biological components. Your laboratory benefits from its ability to rapidly concentrate and purify samples, making it essential for blood component separation and vaccine production. This technique also plays a critical role in oil and dairy industries by facilitating the clarification and purification of liquids.

Advantages of Membrane Filtration

Membrane filtration offers precise separation based on particle size, enabling effective removal of microorganisms and impurities without changing the chemical composition of the sample. It operates at lower energy consumption compared to centrifugation, making it more cost-efficient and environmentally friendly for your filtration needs. The process also provides scalability and ease of automation, which enhances consistency and throughput in diverse industries such as water treatment and pharmaceuticals.

Advantages of Centrifugation

Centrifugation offers rapid separation of particles based on density differences, making it ideal for processing large sample volumes efficiently. It provides high precision in isolating cells, proteins, and other biomolecules without the need for filter replacement or clogging issues common in membrane filtration. The technique requires less maintenance and can handle complex mixtures with varying particle sizes, enhancing its versatility in laboratory and industrial applications.

Limitations and Challenges of Each Method

Membrane filtration faces challenges such as membrane fouling, limited pore size range, and high operational costs for cleaning or replacement, which can reduce efficiency over time. Centrifugation struggles with high energy consumption, shear stress on sensitive particles, and limited separation resolution for particles with similar densities, impacting overall performance. Your choice depends on balancing these limitations with sample type and required purity levels to optimize separation outcomes.

Choosing the Right Separation Technique

Selecting the appropriate separation technique depends on factors such as particle size, sample volume, and desired purity level. Membrane filtration excels in removing microorganisms and fine particulates through selective porous membranes, ideal for sterilization and clarification. Centrifugation offers rapid phase separation based on density differences, suitable for large volumes and separating cells, organelles, or emulsions efficiently.

Membrane Filtration vs Centrifugation Infographic

libmatt.com

libmatt.com