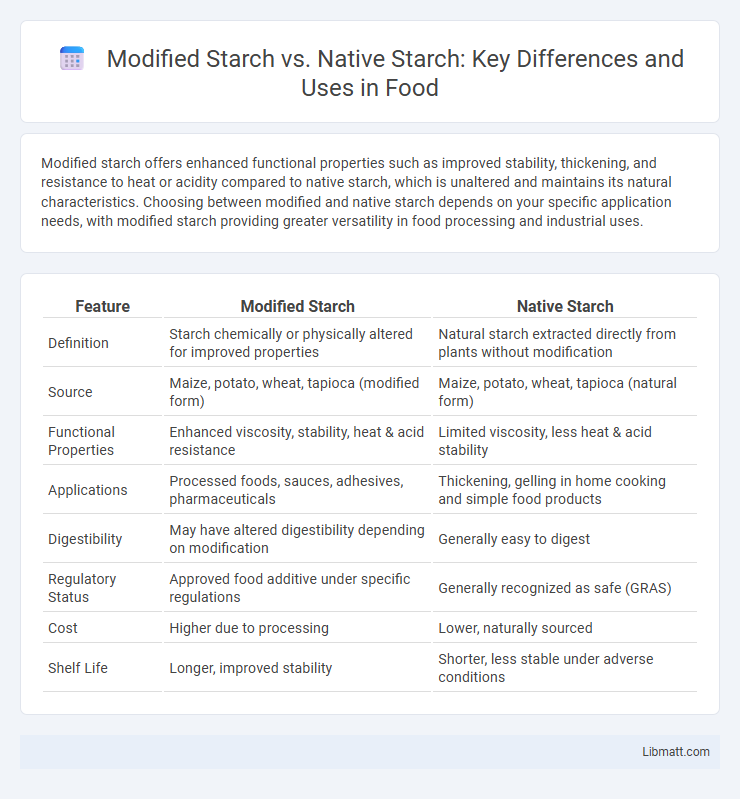

Modified starch offers enhanced functional properties such as improved stability, thickening, and resistance to heat or acidity compared to native starch, which is unaltered and maintains its natural characteristics. Choosing between modified and native starch depends on your specific application needs, with modified starch providing greater versatility in food processing and industrial uses.

Table of Comparison

| Feature | Modified Starch | Native Starch |

|---|---|---|

| Definition | Starch chemically or physically altered for improved properties | Natural starch extracted directly from plants without modification |

| Source | Maize, potato, wheat, tapioca (modified form) | Maize, potato, wheat, tapioca (natural form) |

| Functional Properties | Enhanced viscosity, stability, heat & acid resistance | Limited viscosity, less heat & acid stability |

| Applications | Processed foods, sauces, adhesives, pharmaceuticals | Thickening, gelling in home cooking and simple food products |

| Digestibility | May have altered digestibility depending on modification | Generally easy to digest |

| Regulatory Status | Approved food additive under specific regulations | Generally recognized as safe (GRAS) |

| Cost | Higher due to processing | Lower, naturally sourced |

| Shelf Life | Longer, improved stability | Shorter, less stable under adverse conditions |

Introduction to Starch: Native vs Modified

Native starch is a natural carbohydrate extracted from plants such as corn, wheat, and potatoes, consisting primarily of amylose and amylopectin molecules. Modified starch undergoes physical, enzymatic, or chemical treatments to alter its functional properties, improving stability, solubility, or texture in food and industrial applications. Differences in gelatinization temperature, viscosity, and resistance to retrogradation make modified starch preferred over native starch in complex formulations requiring enhanced performance.

Chemical Structure Differences

Modified starches undergo physical, enzymatic, or chemical treatments altering their molecular structure, enhancing properties like stability and solubility, while native starch retains its original amylose and amylopectin composition. Chemical modifications often introduce functional groups such as acetyl, phosphate, or hydroxypropyl, changing gelatinization, retrogradation, and viscosity characteristics. Understanding these chemical structure differences helps you select the appropriate starch type for specific food, pharmaceutical, or industrial applications.

Manufacturing Processes

Modified starch undergoes chemical, physical, or enzymatic treatments such as oxidation, acid hydrolysis, or cross-linking to alter its functional properties, resulting in enhanced stability, viscosity, and resistance to heat or shear. Native starch is extracted directly from plants like corn, tapioca, or potato through wet milling and drying without additional processing, retaining its original granular structure and gelatinization characteristics. The manufacturing process of modified starch involves precise control of reaction conditions to target specific functional improvements, distinguishing it clearly from the simpler extraction process of native starch.

Functional Properties Comparison

Modified starch exhibits enhanced functional properties compared to native starch, including improved stability under extreme pH, temperature, and shear conditions, making it ideal for diverse industrial applications. Native starch maintains its natural granular structure, providing unique thickening and gelling characteristics but with limited resistance to processing hardships. Understanding these differences helps you select the appropriate starch type to optimize texture, viscosity, and shelf-life in your food, pharmaceutical, or cosmetic formulations.

Applications in Food Industry

Modified starch offers enhanced functional properties such as improved texture, stability, and resistance to heat and acid, making it ideal for processed foods, sauces, and baked goods. Native starch is frequently used in products requiring natural thickening and gelling without chemical alteration, such as puddings, soups, and baby foods. Your choice between modified and native starch depends on the specific application requirements, including processing conditions and desired product characteristics.

Benefits of Modified Starch

Modified starch offers enhanced functional properties such as improved texture, stability, and resistance to heat, acids, and shear compared to native starch. It provides better thickening, gelling, and emulsifying capabilities, making it ideal for diverse food, pharmaceutical, and industrial applications. Your formulations can achieve longer shelf life and consistent quality using modified starch.

Limitations of Native Starch

Native starch has limited stability under varying temperature, pH, and shear conditions, resulting in poor thickening and gelling properties in food processing. Its native structure also causes susceptibility to retrogradation and syneresis, leading to undesirable texture changes over time. You may encounter processing challenges and reduced shelf-life when relying solely on native starch in complex formulations.

Health and Safety Considerations

Modified starch often undergoes chemical or physical treatments that may introduce additives or residual chemicals, raising concerns about potential allergenicity or digestive tolerance for some individuals. Native starch, derived directly from natural sources without alteration, is generally recognized as safe and less likely to cause adverse health effects or allergic reactions. Understanding these health and safety considerations can help you make informed choices based on dietary needs and sensitivities.

Regulatory Status and Labeling

Modified starches undergo chemical, physical, or enzymatic treatments that often require specific regulatory approval depending on the country, with agencies like the FDA in the United States or EFSA in the European Union listing approved modifications and usage limits. Native starches, being unaltered natural products, typically do not require separate regulatory approval and are labeled simply as starch on ingredient lists. Labeling regulations mandate that modified starches be clearly identified by their specific modification type to inform consumers and ensure compliance with food safety standards.

Future Trends in Starch Technology

Future trends in starch technology emphasize the development of modified starches with enhanced functional properties such as improved gelatinization, stability, and digestibility to meet the demands of food, pharmaceutical, and biodegradable packaging industries. Advances in enzymatic modification and physical treatments are driving innovations in producing starches that reduce environmental impact and increase sustainability. The integration of nanotechnology and bioengineering is expected to further expand the applications and performance of modified starches over native starches in diverse industrial sectors.

Modified Starch vs Native Starch Infographic

libmatt.com

libmatt.com