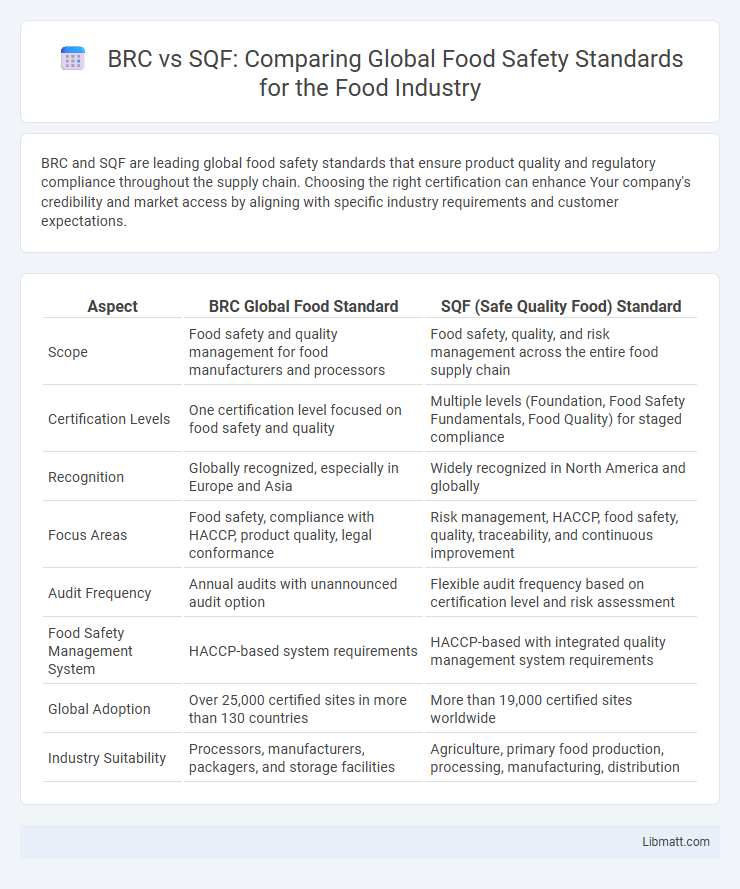

BRC and SQF are leading global food safety standards that ensure product quality and regulatory compliance throughout the supply chain. Choosing the right certification can enhance Your company's credibility and market access by aligning with specific industry requirements and customer expectations.

Table of Comparison

| Aspect | BRC Global Food Standard | SQF (Safe Quality Food) Standard |

|---|---|---|

| Scope | Food safety and quality management for food manufacturers and processors | Food safety, quality, and risk management across the entire food supply chain |

| Certification Levels | One certification level focused on food safety and quality | Multiple levels (Foundation, Food Safety Fundamentals, Food Quality) for staged compliance |

| Recognition | Globally recognized, especially in Europe and Asia | Widely recognized in North America and globally |

| Focus Areas | Food safety, compliance with HACCP, product quality, legal conformance | Risk management, HACCP, food safety, quality, traceability, and continuous improvement |

| Audit Frequency | Annual audits with unannounced audit option | Flexible audit frequency based on certification level and risk assessment |

| Food Safety Management System | HACCP-based system requirements | HACCP-based with integrated quality management system requirements |

| Global Adoption | Over 25,000 certified sites in more than 130 countries | More than 19,000 certified sites worldwide |

| Industry Suitability | Processors, manufacturers, packagers, and storage facilities | Agriculture, primary food production, processing, manufacturing, distribution |

Introduction to Global Food Safety Standards

Global food safety standards such as BRC (British Retail Consortium) and SQF (Safe Quality Food) provide comprehensive frameworks for ensuring food quality and safety across supply chains. BRC is widely recognized for its rigorous certification process emphasizing hazard analysis and risk management, while SQF integrates food safety and quality management systems with a strong focus on continuous improvement and compliance with regulatory requirements. Both standards facilitate international trade by harmonizing food safety protocols, thereby enhancing consumer confidence and reducing product recalls.

Overview of BRC and SQF Certifications

BRC Global Standards and SQF (Safe Quality Food) are leading food safety certification programs recognized worldwide for their rigorous compliance requirements and comprehensive risk management frameworks. BRC certification emphasizes supplier approval, internal auditing, and traceability, while SQF is known for its detailed food safety plans and HACCP-based approach tailored for the entire supply chain. Your choice between BRC and SQF certifications depends on specific market demands and client preferences within the global food industry.

Key Differences Between BRC and SQF

BRC (British Retail Consortium) and SQF (Safe Quality Food) are globally recognized food safety standards with distinct scopes and certification requirements. BRC emphasizes product safety, quality, and operational criteria targeting retailers, while SQF integrates food safety and quality management with a broader focus, including supplier management tailored for diverse supply chains. Certification processes differ, as BRC requires more frequent audits and detailed site-specific assessments, whereas SQF offers multi-tiered certifications aligned with HACCP principles adaptable to various industry sectors.

Certification Process Comparison

The BRC certification process requires a detailed gap analysis, risk assessment, and scheduled audits focusing on product safety and quality management systems, with certification valid for 12 months before re-assessment. The SQF certification process involves an initial site registration, a pre-certification audit option, followed by an annual certification audit conducted by an SQF-licensed auditor, emphasizing food safety plans aligned with HACCP principles. Both standards mandate third-party audits and ongoing compliance but differ in documentation complexity and focus areas, with BRC emphasizing supplier management and SQF prioritizing food safety system adaptability.

Documentation and Record-Keeping Requirements

BRC Global Standards demand comprehensive documentation and precise record-keeping to ensure compliance with food safety management systems, emphasizing traceability and audit readiness. SQF (Safe Quality Food) standards mandate detailed records of manufacturing processes, supplier verification, and corrective actions to maintain certification and demonstrate continuous improvement. Your food safety program benefits from understanding these differences to optimize record-keeping efficiency and regulatory adherence.

Audit Procedures: BRC vs SQF

BRC audit procedures emphasize a systematic, risk-based approach with a strong focus on product safety, quality management, and site management requirements, typically conducted annually with unannounced options available. SQF audits are divided into Stage 1 (documentation review) and Stage 2 (on-site system assessment), ensuring compliance with food safety, quality, and regulatory requirements through announced or unannounced audits depending on your certification level. Both standards require detailed corrective action plans post-audit, but SQF places a stronger emphasis on supplier approval and verification processes within its audit framework.

Industry Adoption and Global Recognition

BRC and SQF are both globally recognized food safety standards with widespread industry adoption across various sectors. BRC enjoys strong popularity in Europe and the UK, while SQF is highly regarded in North America and Australia, reflecting regional preferences. Your choice may depend on target markets, with BRC favored by many retailers and SQF recognized for compliance ease in regulated environments.

Cost Implications of BRC and SQF

The cost implications of BRC (British Retail Consortium) and SQF (Safe Quality Food) certifications vary based on factors such as audit frequency, facility size, and complexity of food safety systems. BRC certification often incurs higher initial certification fees due to its comprehensive audit requirements and stringent documentation standards, while SQF certification may lead to ongoing costs related to maintaining a tiered approach and integrating food safety with quality management. Both standards require investment in training, continuous compliance, and third-party audits, with companies weighing cost against market access and brand reputation benefits.

Pros and Cons: BRC vs SQF

BRC (British Retail Consortium) offers strong global recognition and a comprehensive approach to food safety, with a focus on supplier management, but it can be complex and resource-intensive to implement. SQF (Safe Quality Food) emphasizes practical application and is highly recognized in North America, providing a scalable framework suited for various food sectors, though it may require additional effort for international acceptance. Your choice depends on market requirements and operational capacity, balancing BRC's rigorous certification with SQF's flexible, implementation-friendly standards.

Choosing the Right Standard for Your Business

Selecting the right global food safety standard significantly impacts your business's market access and consumer trust. BRC (British Retail Consortium) emphasizes product safety, quality, and legality, making it ideal for UK and European markets, while SQF (Safe Quality Food) offers a comprehensive approach recognized widely in North America and supports food safety and quality throughout the supply chain. Understanding your target market, regulatory requirements, and operational goals helps determine whether BRC or SQF aligns best with your business growth and compliance needs.

BRC vs SQF (Global Food Standards) Infographic

libmatt.com

libmatt.com