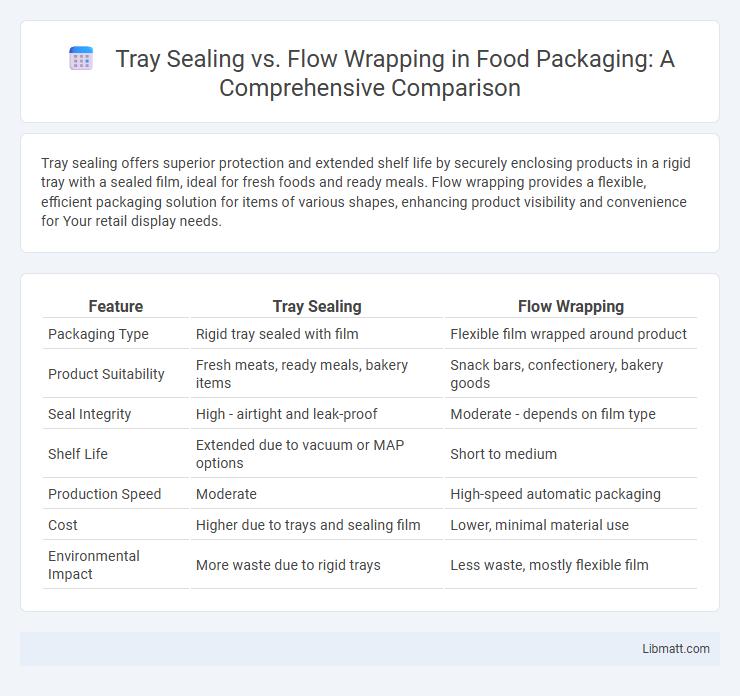

Tray sealing offers superior protection and extended shelf life by securely enclosing products in a rigid tray with a sealed film, ideal for fresh foods and ready meals. Flow wrapping provides a flexible, efficient packaging solution for items of various shapes, enhancing product visibility and convenience for Your retail display needs.

Table of Comparison

| Feature | Tray Sealing | Flow Wrapping |

|---|---|---|

| Packaging Type | Rigid tray sealed with film | Flexible film wrapped around product |

| Product Suitability | Fresh meats, ready meals, bakery items | Snack bars, confectionery, bakery goods |

| Seal Integrity | High - airtight and leak-proof | Moderate - depends on film type |

| Shelf Life | Extended due to vacuum or MAP options | Short to medium |

| Production Speed | Moderate | High-speed automatic packaging |

| Cost | Higher due to trays and sealing film | Lower, minimal material use |

| Environmental Impact | More waste due to rigid trays | Less waste, mostly flexible film |

Introduction to Tray Sealing and Flow Wrapping

Tray sealing involves sealing food products in pre-formed trays with a plastic film to enhance freshness and extend shelf life, commonly used for meat, ready meals, and fresh produce. Flow wrapping is a continuous process where products are wrapped in a flexible film that is sealed on both ends and along the length, ideal for snacks, bakery items, and confectionery. Both methods optimize packaging efficiency and product protection, with tray sealing offering rigid support and flow wrapping providing flexible, lightweight packaging.

Key Differences Between Tray Sealing and Flow Wrapping

Tray sealing creates a rigid package by sealing a lidded film onto a pre-formed tray, providing enhanced protection and extended shelf life for perishable products. Flow wrapping envelops products in a continuous roll of film, sealing them in a flexible, airtight package ideal for irregularly shaped items and high-speed production. The key differences lie in tray sealing's structural support and barrier properties versus flow wrapping's adaptability and efficiency in packaging diverse product shapes.

Advantages of Tray Sealing

Tray sealing offers superior protection for your products by securely enclosing them in rigid trays, which enhances shelf life and reduces contamination risks. The process supports high-speed production with minimal material waste, making it cost-effective for bulk packaging needs. Its compatibility with various tray materials and easy customization options ensures optimal product presentation and durability.

Benefits of Flow Wrapping

Flow wrapping offers superior flexibility and efficiency in packaging various product shapes and sizes compared to tray sealing. This method enhances product visibility and reduces material waste, improving cost-effectiveness and sustainability. Your packaging process can benefit from faster throughput and better protection against contamination and spoilage.

Packaging Applications: When to Use Tray Sealing

Tray sealing is ideal for packaging fresh food products such as ready meals, meat, and bakery items that require secure containment and extended shelf life through modified atmosphere packaging (MAP). It is commonly used when product presentation, portion control, and durability during transportation are critical factors. Flow wrapping, in contrast, suits high-speed packaging of individual items like confectionery or snacks where flexibility and minimal packaging are preferred.

Ideal Products for Flow Wrapping

Flow wrapping is ideal for packaging items such as confectionery, bakery goods, frozen foods, and small consumer products requiring individual wrapping with high-speed automation. This method provides a tight, clear seal that protects products from moisture and contamination while maintaining product visibility, making it suitable for perishable and promotional items. Flow wrapping excels in packaging irregularly shaped products and those that demand a tamper-evident, hygienic barrier.

Packaging Speed and Efficiency Comparison

Tray sealing machines typically offer higher packaging speeds, reaching up to 80 trays per minute, making them ideal for large-scale food production lines. Flow wrapping, while slightly slower at around 60 packages per minute, provides greater flexibility for varying product sizes and shapes, enhancing overall efficiency in diverse packaging scenarios. Efficiency in tray sealing is maximized through automated label application and integrated sealing processes, whereas flow wrapping excels with minimal material waste and quick changeovers.

Material Compatibility in Tray Sealing vs Flow Wrapping

Tray sealing is highly compatible with rigid containers made from materials such as plastic, aluminum, and cardboard, allowing for secure sealing and extended shelf life. Flow wrapping primarily uses flexible materials like polyethylene, polypropylene, and laminated films, offering a tight, protective wrap around irregularly shaped items. Both methods require careful selection of materials to ensure barrier properties, machinability, and product protection tailored to specific packaging needs.

Cost Considerations and ROI Analysis

Tray sealing typically involves higher initial equipment costs compared to flow wrapping but offers superior product protection and extended shelf life, which can enhance your ROI over time. Flow wrapping machines generally have lower upfront expenses and faster speeds, making them cost-effective for high-volume, lower-margin products. Evaluating your product type, production volume, and packaging requirements is essential to determine which method maximizes cost efficiency and return on investment.

Sustainability and Environmental Impact

Tray sealing and flow wrapping differ in sustainability and environmental impact, as tray sealing typically uses rigid plastic trays that can be less eco-friendly due to limited recyclability. Flow wrapping often employs flexible films that require less material and generate less waste, improving your package's carbon footprint. Choosing flow wrapping over tray sealing can enhance environmental responsibility by minimizing plastic use and facilitating easier recycling processes.

Tray Sealing vs Flow Wrapping Infographic

libmatt.com

libmatt.com