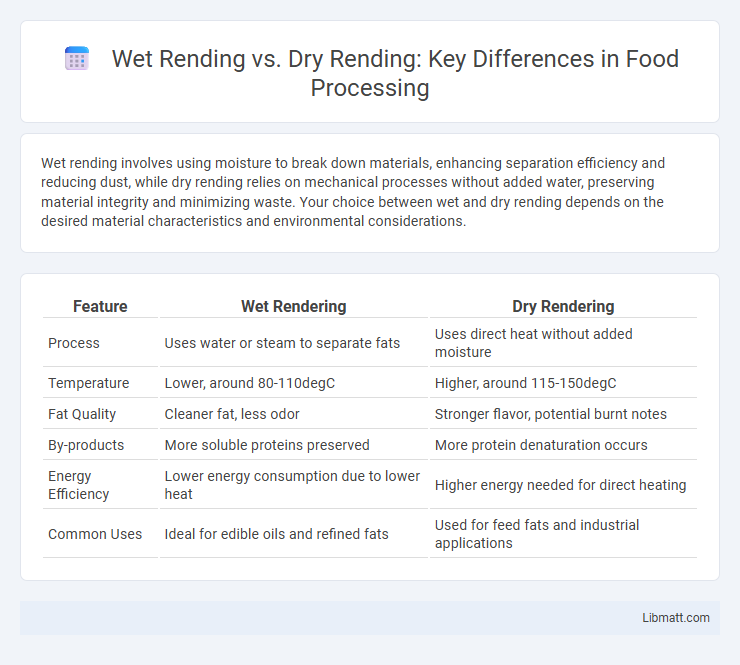

Wet rending involves using moisture to break down materials, enhancing separation efficiency and reducing dust, while dry rending relies on mechanical processes without added water, preserving material integrity and minimizing waste. Your choice between wet and dry rending depends on the desired material characteristics and environmental considerations.

Table of Comparison

| Feature | Wet Rendering | Dry Rendering |

|---|---|---|

| Process | Uses water or steam to separate fats | Uses direct heat without added moisture |

| Temperature | Lower, around 80-110degC | Higher, around 115-150degC |

| Fat Quality | Cleaner fat, less odor | Stronger flavor, potential burnt notes |

| By-products | More soluble proteins preserved | More protein denaturation occurs |

| Energy Efficiency | Lower energy consumption due to lower heat | Higher energy needed for direct heating |

| Common Uses | Ideal for edible oils and refined fats | Used for feed fats and industrial applications |

Introduction to Wet Rending and Dry Rending

Wet rending involves processing raw materials with added moisture, enhancing fiber separation and improving the quality of the final product, commonly used in textile and hemp industries. Dry rending, by contrast, processes materials without added water, relying on mechanical means to separate fibers, which is often faster but may result in coarser textures. Understanding the differences between wet rending and dry rending can help you select the appropriate method based on your production needs and desired fiber characteristics.

What is Wet Rending?

Wet rending is a process used to separate fibers, typically in the textile or paper recycling industries, by soaking materials in water to soften them before mechanical separation. This method enhances fiber recovery and quality by reducing impurities compared to dry rending, which processes materials without moisture. Wet rending improves the efficiency of fiber extraction and results in cleaner, stronger fibers suitable for high-quality product manufacturing.

What is Dry Rending?

Dry rending is a mechanical process used to separate fibers from raw hides or skins without applying water, preserving the natural properties of the material. This method involves using specialized equipment to break down the connective tissue and remove unwanted substances, resulting in cleaner collagen extraction ideal for leather production or gelatin manufacturing. Compared to wet rending, dry rending reduces water usage, minimizes waste treatment, and improves overall efficiency in processing animal by-products.

Key Differences Between Wet and Dry Rending

Wet rending involves mixing materials with water, resulting in a smoother, more workable plaster that adheres better to surfaces and reduces dust during application. Dry rending uses pre-mixed dry materials applied directly to a surface, offering faster application but with a rougher finish and increased dust generation. The choice between wet and dry rending impacts drying time, surface texture, and labor intensity in construction projects.

Historical Context of Rending Methods

Wet rending, historically linked to traditional papermaking practices in East Asia, involves soaking fibers before processing, enhancing fiber separation and pulp quality; dry rending, conversely, roots in Western textile and fiber industries, where mechanical separation of dry fibers dominates. The evolution of these methods reflects regional resource availability and technological advancements, shaping contemporary fiber processing techniques. Understanding the historical context highlights how wet and dry rending methods influenced modern applications in paper, textiles, and composite materials manufacturing.

Step-by-Step Wet Rending Process

The step-by-step wet rending process begins with soaking the grains or beans in water to soften their outer husks, facilitating easier separation. Next, the softened material undergoes mechanical milling in the presence of water, which helps separate the endosperm from the fiber and germ. Finally, the slurry is screened and centrifuged to isolate the desired starch or protein components, producing higher purity yields compared to dry rending techniques.

Step-by-Step Dry Rending Process

Dry rending involves mechanically separating fat from tissue without moisture, using a combination of grinding, chopping, and pressing techniques. You begin by placing frozen or chilled fatty tissue into a grinding machine, which breaks it down into smaller pieces before the meat is passed through a series of mechanical presses to extract the rendered fat. This step-by-step dry rending process produces high-quality fat suitable for culinary or industrial use, maintaining purity without introducing water or steam.

Comparing Efficiency and Yield

Wet rending typically offers higher efficiency and yield compared to dry rending by allowing better separation of fibers through hydration, which reduces fiber damage and loss. Dry rending often results in lower yield due to increased fiber breakage and poor loosening, making the process less efficient overall. Optimizing your fiber extraction process involves choosing wet rending for maximizing output and preserving fiber quality.

Applications and End Products

Wet rending is commonly used in biodiesel production and animal feed applications due to its efficiency in extracting high-quality proteins and oils from animal tissues, resulting in moist, nutrient-rich end products. Dry rending, favored in soap making and oleochemical industries, yields dry, stable tallow and protein meals suitable for long-term storage and transport. Your choice between these methods depends on the desired end product's moisture content and application requirements.

Choosing the Best Rending Method for Your Needs

Wet rending involves applying a mixture of cement and sand with water to create a smooth, durable finish ideal for exterior walls requiring weather resistance. Dry rending uses a pre-mixed dry compound that is applied without water, offering faster application and easier touch-ups, suitable for interior surfaces or quick repairs. Selecting the best rending method depends on factors such as climate exposure, desired finish quality, project time constraints, and surface type to ensure optimal durability and aesthetics.

Wet Rending vs Dry Rending Infographic

libmatt.com

libmatt.com