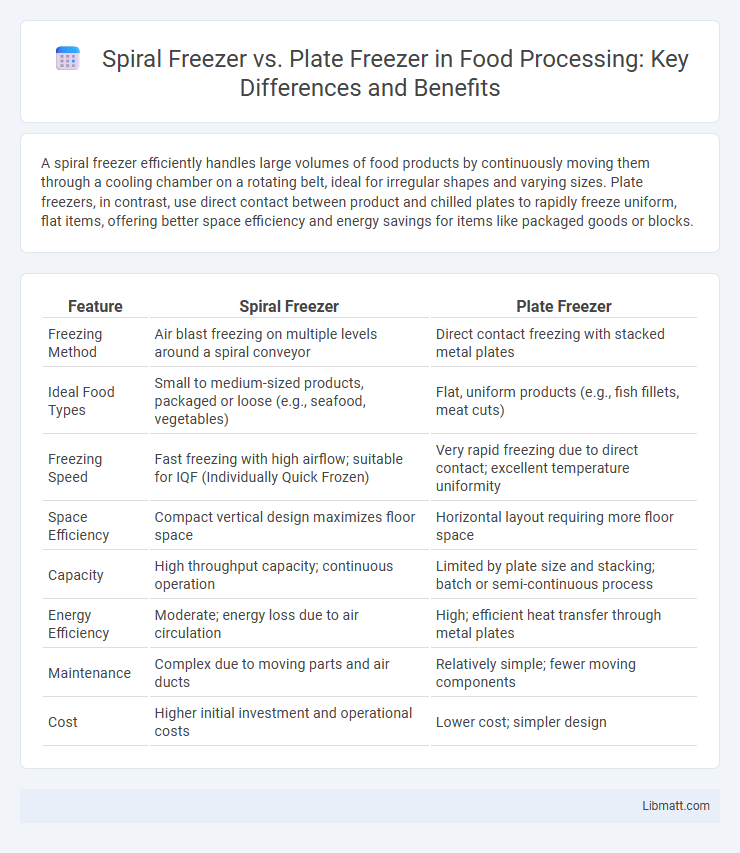

A spiral freezer efficiently handles large volumes of food products by continuously moving them through a cooling chamber on a rotating belt, ideal for irregular shapes and varying sizes. Plate freezers, in contrast, use direct contact between product and chilled plates to rapidly freeze uniform, flat items, offering better space efficiency and energy savings for items like packaged goods or blocks.

Table of Comparison

| Feature | Spiral Freezer | Plate Freezer |

|---|---|---|

| Freezing Method | Air blast freezing on multiple levels around a spiral conveyor | Direct contact freezing with stacked metal plates |

| Ideal Food Types | Small to medium-sized products, packaged or loose (e.g., seafood, vegetables) | Flat, uniform products (e.g., fish fillets, meat cuts) |

| Freezing Speed | Fast freezing with high airflow; suitable for IQF (Individually Quick Frozen) | Very rapid freezing due to direct contact; excellent temperature uniformity |

| Space Efficiency | Compact vertical design maximizes floor space | Horizontal layout requiring more floor space |

| Capacity | High throughput capacity; continuous operation | Limited by plate size and stacking; batch or semi-continuous process |

| Energy Efficiency | Moderate; energy loss due to air circulation | High; efficient heat transfer through metal plates |

| Maintenance | Complex due to moving parts and air ducts | Relatively simple; fewer moving components |

| Cost | Higher initial investment and operational costs | Lower cost; simpler design |

Introduction to Spiral Freezers and Plate Freezers

Spiral freezers utilize a continuous belt that moves products through a refrigerated spiral tunnel, enabling efficient freezing with minimal floor space. Plate freezers employ stacked, chilled plates that freeze food items placed between them, providing rapid heat transfer and uniform freezing. Both systems optimize freezing processes but differ in application based on product type, production volume, and spatial constraints.

How Spiral Freezers Work

Spiral freezers operate by continuously moving products on a conveyor belt that winds around a vertical spiral frame, exposing items to cold air in a compact footprint. This design maximizes freezing efficiency by increasing product surface area exposure to low temperatures while maintaining airflow, ideal for high-volume, small-sized food items. The controlled airflow and consistent temperature ensure rapid freezing, preserving product quality and extending shelf life.

How Plate Freezers Function

Plate freezers function by placing products between horizontal, refrigerated metal plates that rapidly absorb heat through direct contact, ensuring efficient and uniform freezing. The compression of products between these plates maximizes surface area exposure, significantly reducing freezing time compared to air-based methods. Your frozen goods benefit from consistent temperature control, preserving quality and texture during storage and transportation.

Key Differences Between Spiral and Plate Freezers

Spiral freezers use a continuous belt system to freeze products rapidly in a vertical, space-efficient design, ideal for items like seafood, bakery, and ready meals. Plate freezers, featuring horizontal freezing plates that clamp products between chilled surfaces, offer direct contact cooling suited for block or packaged foods requiring uniform freezing. Your choice depends on product type, production volume, and space availability, with spiral freezers excelling in throughput and plate freezers providing precise temperature control.

Applications of Spiral Freezers in Food Processing

Spiral freezers are extensively used in the food processing industry for freezing various products such as bakery goods, ready meals, seafood, and poultry due to their high capacity and continuous processing capabilities. Their design allows for efficient utilization of space and gentle handling, making them ideal for delicate or irregularly shaped items. These freezers excel in maintaining product quality and texture by providing rapid freezing times, which reduces ice crystal formation and preserves flavor.

Use Cases for Plate Freezers

Plate freezers are ideal for freezing flat or uniform products such as fish fillets, meat patties, and prepared foods, providing rapid and even freezing through direct contact with chilled plates. They excel in small to medium-scale operations requiring efficient space utilization and precise temperature control to maintain product quality. Common industries using plate freezers include seafood processing, meat packing, and ready-meal manufacturers seeking to preserve texture and freshness.

Energy Efficiency Comparison

Spiral freezers generally offer higher energy efficiency compared to plate freezers due to their continuous airflow and uniform temperature distribution, which reduces energy consumption during freezing. Plate freezers often require more energy to maintain consistent contact and pressure between plates and products, leading to higher operational costs. Energy use in spiral freezers can be optimized with variable speed drives and advanced insulation, making them ideal for high-volume, rapid freezing applications.

Space and Footprint Considerations

Spiral freezers offer a compact design by stacking multiple freezing layers vertically, which maximizes space efficiency and reduces the overall footprint in your facility. Plate freezers require more horizontal floor space due to their flat, side-by-side freezing plates, making them less suitable for facilities with limited square footage. Choosing between the two depends largely on your spatial constraints and production volume requirements.

Product Quality and Freezing Time

Spiral freezers offer rapid freezing with uniform airflow, preserving product quality by minimizing ice crystal formation and maintaining texture and flavor. Plate freezers deliver efficient heat transfer through direct contact, resulting in faster freezing times for solid blocks or packaged products but may cause surface freezing inconsistencies in delicate items. Your choice depends on balancing the need for quick freezing and optimal preservation of product integrity.

Choosing the Right Freezer for Your Business

Spiral freezers provide continuous freezing with high capacity, ideal for large-scale production and delicate products requiring gentle handling, while plate freezers offer rapid freezing in compact spaces, perfect for small batches and uniform items. Your choice depends on production volume, space constraints, and product type, ensuring optimal efficiency and product quality. Evaluating factors like freezing speed, footprint, and cost-effectiveness will help you select the right freezer for your business needs.

spiral freezer vs plate freezer Infographic

libmatt.com

libmatt.com