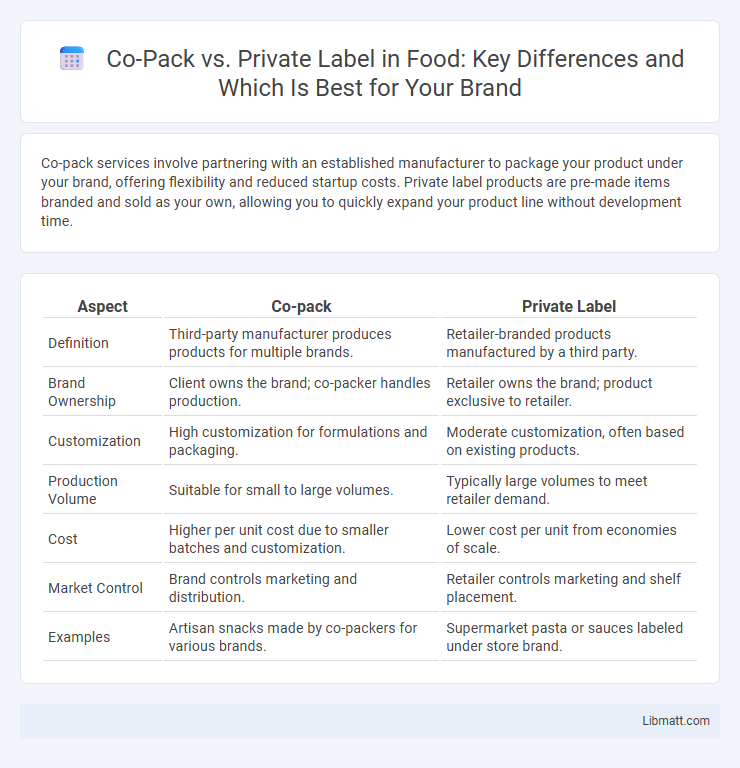

Co-pack services involve partnering with an established manufacturer to package your product under your brand, offering flexibility and reduced startup costs. Private label products are pre-made items branded and sold as your own, allowing you to quickly expand your product line without development time.

Table of Comparison

| Aspect | Co-pack | Private Label |

|---|---|---|

| Definition | Third-party manufacturer produces products for multiple brands. | Retailer-branded products manufactured by a third party. |

| Brand Ownership | Client owns the brand; co-packer handles production. | Retailer owns the brand; product exclusive to retailer. |

| Customization | High customization for formulations and packaging. | Moderate customization, often based on existing products. |

| Production Volume | Suitable for small to large volumes. | Typically large volumes to meet retailer demand. |

| Cost | Higher per unit cost due to smaller batches and customization. | Lower cost per unit from economies of scale. |

| Market Control | Brand controls marketing and distribution. | Retailer controls marketing and shelf placement. |

| Examples | Artisan snacks made by co-packers for various brands. | Supermarket pasta or sauces labeled under store brand. |

Understanding Co-Pack and Private Label

Co-pack refers to outsourcing the manufacturing and packaging of products to a third-party company that follows the brand owner's specifications, enabling efficient production without investing in facilities. Private label involves retailers or companies branding and selling products made by another manufacturer under their own brand name, allowing faster market entry and product diversification. Both strategies optimize supply chains and brand presence while reducing the need for in-house production capabilities.

Key Differences Between Co-Pack and Private Label

Co-pack involves outsourcing the manufacturing process to a third-party company that produces products based on the client's specifications, whereas private label entails branding existing products made by a manufacturer under the retailer's brand name. Co-packers typically provide customized production services, including formulation, packaging, and labeling, enabling brands to maintain control over product development. Private label products are usually pre-formulated and ready for branding, offering faster market entry but less control over product differentiation.

Cost Implications: Co-Pack vs Private Label

Co-pack services typically involve lower upfront costs since you leverage an existing manufacturer's facilities and expertise, reducing expenses for equipment and setup. Private label requires higher initial investment to develop customized products, packaging, and branding, which can increase overall cost but offers greater control and differentiation. Evaluating your budget and scaling strategy helps determine whether co-pack or private label provides the most cost-effective solution for your business goals.

Speed to Market: Which Is Faster?

Co-pack manufacturers typically offer faster speed to market due to their established production lines and streamlined processes, enabling quicker turnaround times for your product launch. Private label products, while customizable, often require longer lead times for design, formulation, and branding approvals, which can delay time to market. Choosing a co-pack partner accelerates your product's entry into the market by leveraging their existing infrastructure and expertise.

Branding Control and Customization

Co-pack solutions offer limited branding control since manufacturers produce products based on predefined recipes and packaging standards, restricting customization options. Private label services provide full branding authority, allowing businesses to design unique packaging, labels, and formulations tailored to target markets. Leveraging private label enhances differentiation and brand identity, while co-pack focuses on cost-efficiency with standardized product offerings.

Quality Assurance and Compliance

Co-packers ensure rigorous Quality Assurance by adhering to standardized manufacturing processes and regulatory requirements to maintain consistent product quality. Private label manufacturers often provide tailored Quality Assurance programs to meet your brand's specific compliance standards and certifications. Both approaches emphasize compliance with FDA regulations, GMP guidelines, and third-party audits to guarantee safe, high-quality products for your customers.

Minimum Order Requirements

Co-pack manufacturers typically set minimum order requirements ranging from 1,000 to 10,000 units, making them more suitable for medium to large-scale production runs. Private label companies may offer lower minimum order quantities, sometimes as low as 100 to 500 units, catering to startups and small businesses seeking flexibility. Understanding these minimum order thresholds is crucial for optimizing production costs and inventory management strategies.

Flexibility in Product Development

Co-pack manufacturers offer greater flexibility in product development by allowing customization of ingredients, packaging, and formulations to meet your specific requirements. Private label products typically follow established formulas with limited customization options, which can restrict innovation. Choosing a co-pack partner enables you to rapidly adapt and innovate your product line to better align with market demands.

When to Choose Co-Pack Over Private Label

Choosing co-pack over private label is ideal when you need customized production that aligns with your specific product formulations and brand standards, offering greater control over ingredient sourcing and manufacturing processes. Co-packing enables flexibility in packaging design, batch sizes, and quality assurance, making it suitable for startups or businesses seeking to maintain unique product identity without investing in manufacturing infrastructure. Your brand benefits from co-packers' expertise while retaining proprietary recipes, which is essential when differentiation and product innovation are priorities.

Making the Right Decision for Your Business

Selecting between co-pack and private label depends on your business goals, budget, and control preferences. Co-packing allows you to leverage established manufacturing expertise and save on production costs with greater flexibility. Your decision should align with product quality, branding control, and scalability to maximize market impact and profitability.

Co-pack vs Private Label Infographic

libmatt.com

libmatt.com