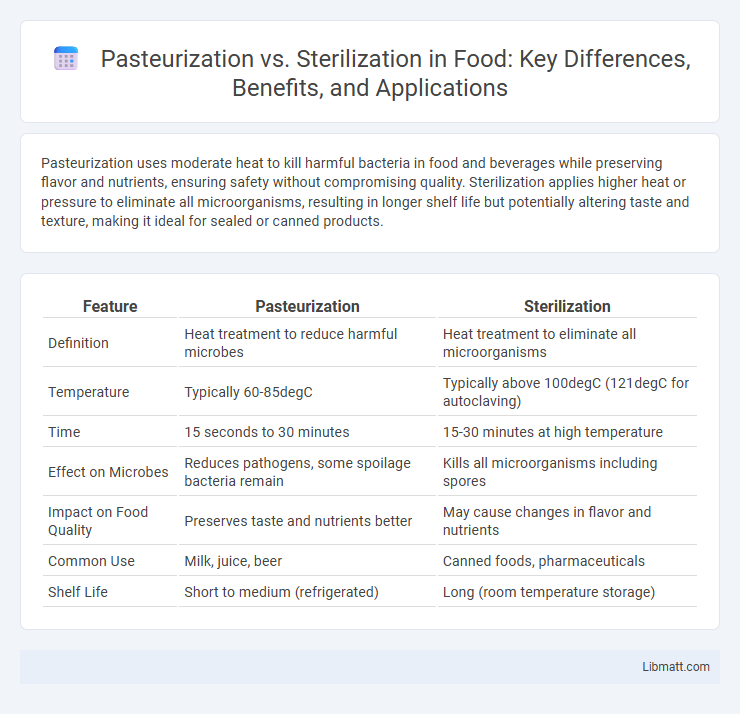

Pasteurization uses moderate heat to kill harmful bacteria in food and beverages while preserving flavor and nutrients, ensuring safety without compromising quality. Sterilization applies higher heat or pressure to eliminate all microorganisms, resulting in longer shelf life but potentially altering taste and texture, making it ideal for sealed or canned products.

Table of Comparison

| Feature | Pasteurization | Sterilization |

|---|---|---|

| Definition | Heat treatment to reduce harmful microbes | Heat treatment to eliminate all microorganisms |

| Temperature | Typically 60-85degC | Typically above 100degC (121degC for autoclaving) |

| Time | 15 seconds to 30 minutes | 15-30 minutes at high temperature |

| Effect on Microbes | Reduces pathogens, some spoilage bacteria remain | Kills all microorganisms including spores |

| Impact on Food Quality | Preserves taste and nutrients better | May cause changes in flavor and nutrients |

| Common Use | Milk, juice, beer | Canned foods, pharmaceuticals |

| Shelf Life | Short to medium (refrigerated) | Long (room temperature storage) |

Introduction to Pasteurization and Sterilization

Pasteurization involves heating liquids to a specific temperature to eliminate harmful microorganisms without compromising flavor or nutritional value, commonly used for milk and juices. Sterilization applies higher temperatures or chemical processes to completely destroy all forms of microbial life, ensuring longer shelf life for medical equipment or canned foods. Understanding the difference between pasteurization and sterilization helps you choose the appropriate method for food safety or sterilization needs.

Definition of Pasteurization

Pasteurization is a heat treatment process that kills harmful bacteria and pathogens in food and beverages without affecting their taste or nutritional value. It typically involves heating the product to a specific temperature, such as 72degC (161degF) for 15 seconds in the case of milk, then rapidly cooling it to extend shelf life while preserving quality. Your understanding of pasteurization helps ensure safer consumption by reducing microbial risks without completely sterilizing the product.

Definition of Sterilization

Sterilization is a process that eliminates all forms of microbial life, including bacteria, viruses, spores, and fungi, ensuring complete decontamination. Unlike pasteurization, which reduces the number of harmful microorganisms to safe levels, sterilization provides a higher level of microbial control suitable for medical equipment, food preservation, and pharmaceuticals. Understanding sterilization is crucial for ensuring your products' safety and extending shelf life without compromising quality.

Main Objectives of Pasteurization and Sterilization

Pasteurization primarily aims to reduce microbial load by targeting pathogenic and spoilage microorganisms to ensure food safety and extend shelf life without significantly altering the product's sensory qualities. Sterilization seeks to achieve complete microbial destruction, including spores, to provide a commercially sterile environment ideal for long-term storage and zero microbial growth. Both processes use heat treatment, but pasteurization operates at lower temperatures and shorter times compared to the high temperatures and longer durations required for sterilization.

Key Differences Between Pasteurization and Sterilization

Pasteurization involves heating liquids to a specific temperature below boiling to eliminate most harmful microbes while preserving taste and nutrients, whereas sterilization uses higher temperatures or chemicals to destroy all forms of microbial life for complete steril safety. Pasteurization is commonly applied to dairy products and juices, ensuring safety without significantly altering quality, while sterilization is critical in medical equipment and canned foods to guarantee long-term storage. Understanding these key differences helps you choose the appropriate method for food safety or equipment hygiene needs.

Methods of Pasteurization

Pasteurization methods include high-temperature short-time (HTST) heating at 72degC for 15 seconds and ultra-pasteurization (UP) at 138degC for 2 seconds, designed to reduce microbial load while preserving product quality. Batch pasteurization (low-temperature long-time, LTLT) involves heating at 63degC for 30 minutes, commonly used for dairy products to eliminate pathogens. These techniques balance microbial safety and nutritional retention, differing from sterilization, which uses higher temperatures and longer times to achieve complete microbial destruction.

Methods of Sterilization

Sterilization methods include autoclaving, which uses high-pressure saturated steam at temperatures around 121degC to kill all microorganisms, including spores. Other techniques involve dry heat sterilization, chemical sterilants like ethylene oxide gas, and filtration for heat-sensitive fluids, ensuring complete elimination of viable microbes. Choosing the appropriate sterilization method depends on the nature of the material you need to process and the specific requirements for microbial control.

Applications in Food and Beverage Industry

Pasteurization is widely used in the food and beverage industry to extend shelf life and ensure safety in products like milk, fruit juices, and beer by heating them to temperatures between 60-85degC for a short time to eliminate pathogenic bacteria while preserving flavor and nutrients. Sterilization involves higher temperatures, often above 121degC, applied through methods such as autoclaving or retort processing, and is primarily used for canned foods, dairy products, and ready-to-eat meals to achieve commercial sterility by destroying all microorganisms, including spores. Both processes play critical roles in food safety, with pasteurization favored for heat-sensitive liquids and sterilization essential for long-term preservation and aseptic packaging.

Advantages and Disadvantages of Each Process

Pasteurization preserves the nutritional value and flavor of food while effectively reducing harmful microorganisms, but it may not eliminate all pathogens, limiting shelf life. Sterilization offers complete microbial destruction, ensuring long-term preservation and safety, yet it can alter taste, texture, and nutrient content due to high heat exposure. Your choice between pasteurization and sterilization depends on the desired balance between product quality and microbial safety.

Choosing the Right Process: Pasteurization vs Sterilization

Choosing the right food safety method depends on your product's shelf life and quality requirements. Pasteurization uses moderate heat to kill harmful microorganisms while preserving taste and nutrients, ideal for products needing refrigeration and a shorter shelf life. Sterilization applies intense heat, ensuring complete microbial destruction for long-term storage without refrigeration but may alter flavor and texture.

pasteurization vs sterilization Infographic

libmatt.com

libmatt.com