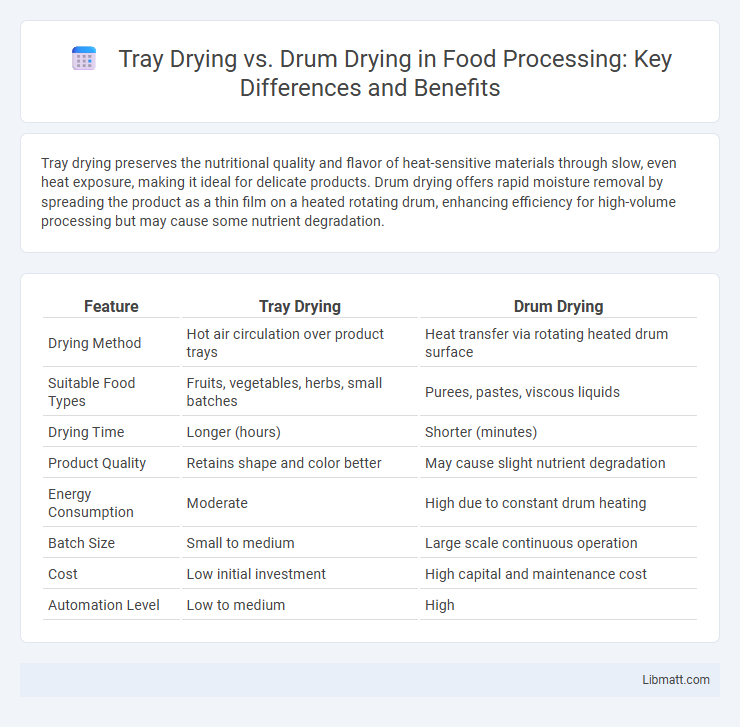

Tray drying preserves the nutritional quality and flavor of heat-sensitive materials through slow, even heat exposure, making it ideal for delicate products. Drum drying offers rapid moisture removal by spreading the product as a thin film on a heated rotating drum, enhancing efficiency for high-volume processing but may cause some nutrient degradation.

Table of Comparison

| Feature | Tray Drying | Drum Drying |

|---|---|---|

| Drying Method | Hot air circulation over product trays | Heat transfer via rotating heated drum surface |

| Suitable Food Types | Fruits, vegetables, herbs, small batches | Purees, pastes, viscous liquids |

| Drying Time | Longer (hours) | Shorter (minutes) |

| Product Quality | Retains shape and color better | May cause slight nutrient degradation |

| Energy Consumption | Moderate | High due to constant drum heating |

| Batch Size | Small to medium | Large scale continuous operation |

| Cost | Low initial investment | High capital and maintenance cost |

| Automation Level | Low to medium | High |

Introduction to Tray Drying and Drum Drying

Tray drying involves spreading materials on trays inside an oven where hot air circulates to remove moisture, making it ideal for heat-sensitive products requiring uniform drying. Drum drying uses a heated rotating drum to instantly dry liquid or slurry into flakes or powders, suitable for high-volume production with rapid drying times. Your choice between these methods depends on the nature of the product and drying efficiency requirements.

How Tray Drying Works

Tray drying operates by spreading materials evenly on perforated trays placed inside a heated chamber where hot air circulates to remove moisture through evaporation. This method provides uniform drying by allowing controlled temperature settings and airflow, making it suitable for heat-sensitive products. The process ensures gradual moisture reduction, preserving the quality and structural integrity of the dried material.

How Drum Drying Works

Drum drying operates by spreading a liquid or slurry onto the surface of a heated rotating drum where water rapidly evaporates, leaving a thin film of dried product that is scraped off by a blade. This method is highly efficient for producing powdered or flaked materials like fruit purees, starches, and dairy products with uniform moisture content. The temperature and drum speed are precisely controlled to optimize drying time and preserve the nutritional and sensory qualities of the product.

Key Differences Between Tray and Drum Drying

Tray drying utilizes heated air circulation to remove moisture from materials placed on perforated trays, offering precise temperature control and suitability for heat-sensitive products. Drum drying involves spreading a liquid or slurry onto the surface of a rotating heated drum, enabling rapid drying and producing powder or flakes, ideal for viscous substances. Key differences include tray drying's batch process with slower moisture removal versus drum drying's continuous, high-speed drying, impacting product texture and energy efficiency.

Advantages of Tray Drying

Tray drying offers precise temperature control and uniform heat distribution, preserving the nutritional quality and flavor of heat-sensitive materials. It allows for easy monitoring and handling of individual samples, making it ideal for small-scale or laboratory applications. This method is energy-efficient and minimizes product contamination due to its enclosed drying environment.

Advantages of Drum Drying

Drum drying offers faster drying times and higher thermal efficiency compared to tray drying, making it ideal for large-scale production. The continuous operation of drum dryers ensures consistent product quality and uniform moisture content. Your process benefits from lower labor costs and reduced space requirements, enhancing overall productivity.

Limitations of Tray Drying

Tray drying is limited by its longer drying times and lower heat transfer efficiency compared to drum drying, making it less suitable for heat-sensitive or bulk materials. The uneven drying rates can lead to inconsistent moisture content, impacting product quality. Your choice may be constrained by these factors if uniformity and rapid processing are critical.

Limitations of Drum Drying

Drum drying often faces limitations such as uneven heating, which can cause product quality inconsistencies and nutrient degradation. The high temperatures used can lead to the loss of heat-sensitive vitamins and flavors, affecting the overall nutritional value and taste of the dried product. Your choice of drying method should consider these constraints if preserving product quality is a priority.

Applications in the Food and Pharmaceutical Industry

Tray drying excels in preserving heat-sensitive nutrients and flavors, making it ideal for drying fruits, vegetables, and pharmaceutical powders requiring gentle moisture removal. Drum drying offers rapid drying of viscous food products like mashed potatoes, baby food, and pharmaceutical pastes by exposing the material to a rotating heated drum, resulting in thin dried sheets that are easily pulverized. Your choice between tray and drum drying depends on the product's heat sensitivity, drying speed requirements, and final texture desired in food and pharmaceutical applications.

Choosing the Right Drying Method: Factors to Consider

Choosing the right drying method depends on factors such as product type, moisture content, and desired quality. Tray drying is ideal for heat-sensitive materials requiring uniform drying, while drum drying suits high-moisture, viscous products needing rapid processing. Your selection should balance efficiency, product integrity, and operational costs to maximize drying performance.

Tray Drying vs Drum Drying Infographic

libmatt.com

libmatt.com