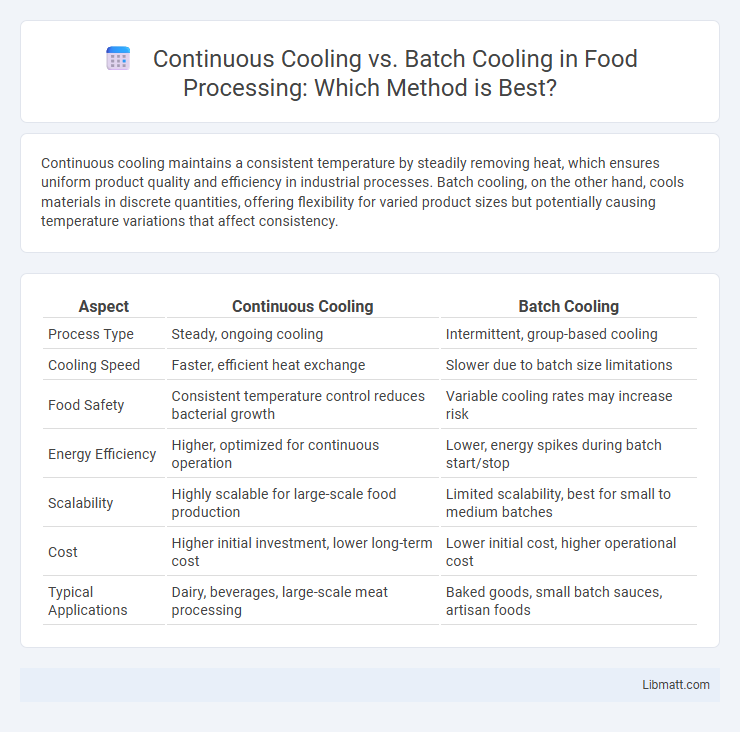

Continuous cooling maintains a consistent temperature by steadily removing heat, which ensures uniform product quality and efficiency in industrial processes. Batch cooling, on the other hand, cools materials in discrete quantities, offering flexibility for varied product sizes but potentially causing temperature variations that affect consistency.

Table of Comparison

| Aspect | Continuous Cooling | Batch Cooling |

|---|---|---|

| Process Type | Steady, ongoing cooling | Intermittent, group-based cooling |

| Cooling Speed | Faster, efficient heat exchange | Slower due to batch size limitations |

| Food Safety | Consistent temperature control reduces bacterial growth | Variable cooling rates may increase risk |

| Energy Efficiency | Higher, optimized for continuous operation | Lower, energy spikes during batch start/stop |

| Scalability | Highly scalable for large-scale food production | Limited scalability, best for small to medium batches |

| Cost | Higher initial investment, lower long-term cost | Lower initial cost, higher operational cost |

| Typical Applications | Dairy, beverages, large-scale meat processing | Baked goods, small batch sauces, artisan foods |

Introduction to Cooling Methods

Continuous cooling involves the steady, uninterrupted removal of heat from materials, ideal for large-scale industrial processes requiring uniform temperature control. Batch cooling, on the other hand, cools materials in discrete quantities, offering greater flexibility and precision for smaller production runs or sensitive products. Your choice between these methods depends on production volume, temperature consistency needs, and process efficiency.

Overview of Continuous Cooling

Continuous cooling involves the uninterrupted removal of heat from a product or process, ensuring consistent temperature control and efficient thermal management. This method is widely used in industrial applications such as chemical processing, food preservation, and metal treatment, where maintaining a steady cooling rate is crucial for product quality. Your choice of continuous cooling can enhance process automation and energy efficiency compared to batch cooling systems.

Overview of Batch Cooling

Batch cooling involves processing a fixed volume of product in discrete batches where the entire batch is cooled uniformly before moving to the next stage. This method offers precise temperature control and uniformity within each batch, making it suitable for products sensitive to temperature fluctuations. Batch cooling systems are commonly used in food processing, pharmaceuticals, and chemical industries where product quality depends on consistent cooling conditions.

Key Differences between Continuous and Batch Cooling

Continuous cooling involves the constant processing of products through a cooling system, maintaining steady temperature control ideal for large-scale industrial operations, whereas batch cooling cools products in discrete quantities or batches, offering flexibility for smaller or varied production runs. Continuous cooling systems typically provide higher efficiency and uniformity, optimizing energy use and product quality, while batch cooling allows more precise control over individual batches, enabling customization and easier adjustments. Your choice between the two depends on production volume, consistency requirements, and operational scale.

Equipment Used in Continuous vs Batch Cooling

Continuous cooling employs equipment such as heat exchangers, cooling tunnels, and spray chillers designed for uninterrupted processing, ensuring consistent temperature control and efficient heat transfer. In contrast, batch cooling utilizes cooling jackets, ice baths, or refrigerated chambers, suitable for discrete product quantities and allowing flexible processing times. The choice of equipment directly impacts the cooling rate, energy efficiency, and scalability of industrial or food processing operations.

Energy Efficiency Comparison

Continuous cooling systems optimize energy use by maintaining steady-state operation and reducing thermal cycling losses, resulting in lower overall energy consumption compared to batch cooling methods. Batch cooling involves frequent heating and cooling cycles that increase energy demand due to repeated temperature fluctuations and system restarts. Studies show continuous coolers can achieve energy savings of up to 30% over batch coolers in industrial applications.

Impact on Product Quality

Continuous cooling ensures more consistent temperature control, reducing the risk of bacterial growth and preserving product freshness, which directly enhances your product quality. Batch cooling may lead to temperature fluctuations, potentially causing uneven cooling and impacting texture, flavor, and shelf life negatively. Maintaining precise temperature management in continuous cooling systems supports superior safety standards and consistent quality outcomes.

Application Examples in Industry

Continuous cooling is widely employed in industries requiring consistent, large-scale production such as steel manufacturing, where it ensures uniform microstructure and mechanical properties through controlled cooling rates. Batch cooling suits applications like food processing and pharmaceuticals, where distinct product lots need tailored cooling profiles to preserve quality and prevent contamination. Your choice depends on production scale, desired product characteristics, and process control requirements in sectors like metallurgy, chemicals, and frozen food storage.

Pros and Cons of Each Cooling Method

Continuous cooling offers consistent temperature control and higher efficiency, making it ideal for large-scale industrial processes, but it requires significant upfront investment and complex maintenance. Batch cooling provides flexibility and simpler operation, suited for smaller batches or variable production runs, though it often results in less uniform cooling and longer processing times. Choosing between these methods depends on production volume, cost constraints, and desired cooling precision.

Choosing the Right Cooling Process

Choosing the right cooling process depends on your production volume and product consistency requirements. Continuous cooling offers efficient, uniform temperature control ideal for large-scale operations, while batch cooling provides flexibility and easier customization for smaller batches or specialized products. Evaluating factors like throughput, product sensitivity, and equipment costs will help determine the most effective cooling method for your needs.

continuous cooling vs batch cooling Infographic

libmatt.com

libmatt.com