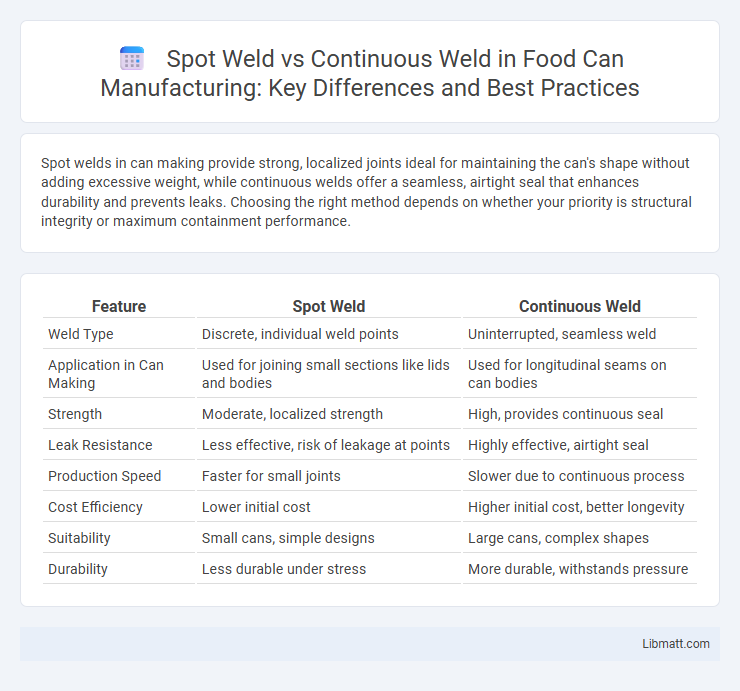

Spot welds in can making provide strong, localized joints ideal for maintaining the can's shape without adding excessive weight, while continuous welds offer a seamless, airtight seal that enhances durability and prevents leaks. Choosing the right method depends on whether your priority is structural integrity or maximum containment performance.

Table of Comparison

| Feature | Spot Weld | Continuous Weld |

|---|---|---|

| Weld Type | Discrete, individual weld points | Uninterrupted, seamless weld |

| Application in Can Making | Used for joining small sections like lids and bodies | Used for longitudinal seams on can bodies |

| Strength | Moderate, localized strength | High, provides continuous seal |

| Leak Resistance | Less effective, risk of leakage at points | Highly effective, airtight seal |

| Production Speed | Faster for small joints | Slower due to continuous process |

| Cost Efficiency | Lower initial cost | Higher initial cost, better longevity |

| Suitability | Small cans, simple designs | Large cans, complex shapes |

| Durability | Less durable under stress | More durable, withstands pressure |

Introduction to Can Making Welds

Spot welds in can making involve localized fusion points that ensure strong joint integrity with minimal heat distortion, ideal for assembling thin metal sheets quickly and efficiently. Continuous welds create an unbroken seam, providing enhanced leak resistance and structural durability vital for certain food and beverage containers requiring airtight seals. The choice between spot and continuous weld techniques impacts production speed, weld strength, and container performance based on specific application requirements.

Fundamentals of Spot Welding

Spot welding joins metal sheets by applying pressure and electric current through copper electrodes at localized points, creating high-strength weld nuggets without melting the entire surface. This process is ideal for thin steel or aluminum cans due to its speed, repeatability, and minimal distortion, making your production efficient and consistent. Understanding spot welding fundamentals ensures optimal weld quality and durability in can manufacturing compared to continuous welds.

Fundamentals of Continuous Welding

Continuous welding in can making involves creating a uniform, uninterrupted seam that enhances airtightness and structural integrity. This method relies on precise control of heat and pressure along the entire joint, ensuring consistent metal fusion and preventing leaks. Its seamless consistency contrasts with spot welding, which joins materials at discrete points and may leave gaps susceptible to corrosion or contamination.

Spot Weld vs Continuous Weld: Key Differences

Spot welds in can making create localized fusion points by applying pressure and heat at discrete spots, providing strong but limited contact areas ideal for joining thin metal sheets quickly. Continuous welds generate a uniform, continuous seam along the joint, ensuring enhanced structural integrity and leak resistance, which is critical for beverage or food cans requiring airtight seals. While spot welds offer faster production speeds and lower costs, continuous welding delivers superior durability and corrosion resistance, making the choice dependent on application-specific performance requirements.

Strength and Durability Comparison

Spot welds in can making provide localized bonding with high shear strength, suitable for areas requiring precision and minimal thermal distortion, while continuous welds offer uniform strength along the seam, enhancing overall durability and resistance to leakage. Continuous welds typically outperform spot welds in applications where consistent load distribution and corrosion resistance are critical, making them ideal for cans exposed to harsh environments. Your choice depends on whether targeted reinforcement or comprehensive seam integrity is prioritized in the manufacturing process.

Production Speed and Efficiency

Spot welds in can making offer faster production speeds due to their quick, localized application, which reduces cycle times and increases overall throughput. Continuous welds, while providing stronger and more uniform seams, require longer processing times that can slow down manufacturing efficiency. Your choice between spot and continuous welding depends on balancing the need for rapid production with the desired structural integrity of the cans.

Cost Analysis: Spot vs Continuous Welding

Spot welding in can making typically incurs lower initial equipment costs and reduces energy consumption by applying localized heat only at specific points, making it more cost-effective for high-volume, lightweight cans. Continuous welding, involving a constant seam fusion, demands higher capital investment and operational expenses due to increased energy use and equipment complexity but offers superior seam strength and leak resistance. Your choice depends on balancing production volume, can durability requirements, and overall budget constraints for optimal cost efficiency.

Suitability for Different Can Materials

Spot weld is ideal for joining thin sheet metals such as aluminum or tinplate used in beverage and food cans, offering precise localized bonding without warping the material. Continuous weld suits thicker or coated metals, providing a strong, seamless seal essential for cans requiring enhanced corrosion resistance or structural integrity. Your choice depends on the can material thickness and coating, balancing weld strength and material compatibility for optimal manufacturing results.

Impact on Can Seal Integrity

Spot welds in can making provide localized heat and pressure that create strong joints with minimal distortion, preserving the integrity of the can seal by preventing thermal damage to sealing surfaces. Continuous welds offer a uniform seam that enhances leak resistance but may introduce heat-related stress, potentially compromising seal durability if not precisely controlled. The choice between spot weld and continuous weld directly influences the can's ability to maintain airtightness and resist contamination during storage.

Choosing the Right Welding Method for Can Making

Choosing the right welding method for can making depends on factors like joint strength, production speed, and material type. Spot welds offer localized, strong connections ideal for thicker materials and high-speed assembly lines, while continuous welds provide a uniform seal that enhances leak resistance and corrosion protection. Your selection should align with the can's functional requirements and manufacturing efficiency to ensure optimal performance and durability.

spot weld vs continuous weld in can making Infographic

libmatt.com

libmatt.com