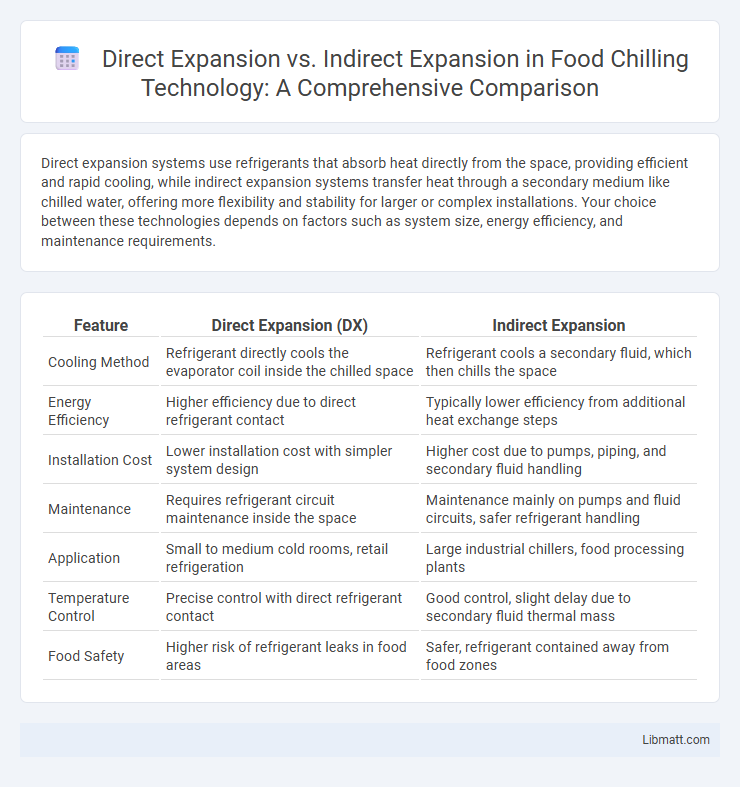

Direct expansion systems use refrigerants that absorb heat directly from the space, providing efficient and rapid cooling, while indirect expansion systems transfer heat through a secondary medium like chilled water, offering more flexibility and stability for larger or complex installations. Your choice between these technologies depends on factors such as system size, energy efficiency, and maintenance requirements.

Table of Comparison

| Feature | Direct Expansion (DX) | Indirect Expansion |

|---|---|---|

| Cooling Method | Refrigerant directly cools the evaporator coil inside the chilled space | Refrigerant cools a secondary fluid, which then chills the space |

| Energy Efficiency | Higher efficiency due to direct refrigerant contact | Typically lower efficiency from additional heat exchange steps |

| Installation Cost | Lower installation cost with simpler system design | Higher cost due to pumps, piping, and secondary fluid handling |

| Maintenance | Requires refrigerant circuit maintenance inside the space | Maintenance mainly on pumps and fluid circuits, safer refrigerant handling |

| Application | Small to medium cold rooms, retail refrigeration | Large industrial chillers, food processing plants |

| Temperature Control | Precise control with direct refrigerant contact | Good control, slight delay due to secondary fluid thermal mass |

| Food Safety | Higher risk of refrigerant leaks in food areas | Safer, refrigerant contained away from food zones |

Introduction to Expansion Technologies in Chilling Systems

Direct Expansion (DX) systems use refrigerants that circulate directly through the evaporator coils to absorb heat, offering faster temperature control and higher efficiency for chilling applications. Indirect Expansion systems rely on a secondary fluid, such as chilled water or glycol, to transfer cooling from the primary refrigerant circuit to the desired area, providing greater flexibility and reduced risk of refrigerant leaks. Your choice between DX and indirect expansion impacts system complexity, maintenance, and energy consumption in chilling technology.

What is Direct Expansion (DX) Cooling?

Direct Expansion (DX) Cooling is a refrigeration method where the refrigerant directly absorbs heat from the air or process through an evaporator coil, enabling efficient and rapid cooling without intermediate heat transfer fluids. This system is widely used in HVAC applications due to its simplicity, compact design, and high energy efficiency, as the refrigerant undergoes phase changes to absorb heat directly from the conditioned space. DX cooling optimizes thermal energy transfer by minimizing energy losses and enhancing temperature control precision in commercial and industrial chilling systems.

What is Indirect Expansion (IX) Cooling?

Indirect Expansion (IX) Cooling employs a secondary cooling medium, such as chilled water or glycol, which absorbs heat from the space before being cooled by the primary refrigerant in the chiller. Unlike Direct Expansion (DX) systems where refrigerant directly cools the air, IX isolates the refrigerant circuit from the air handling units, reducing potential leaks and improving energy efficiency. You benefit from enhanced system flexibility and easier maintenance, making IX cooling ideal for large-scale commercial and industrial applications.

Key Differences Between Direct and Indirect Expansion

Direct Expansion (DX) systems use refrigerant as the primary cooling medium that directly absorbs heat at the evaporator coil, providing efficient and straightforward temperature control. Indirect Expansion systems utilize a secondary fluid, such as chilled water, circulated through heat exchangers to remove heat from the conditioned space, allowing for flexible distribution and reduced refrigerant usage. The key differences include refrigerant placement, heat transfer method, system complexity, and application scalability, with DX systems favoring compact, localized cooling and indirect systems enabling large-scale, centralized chilling.

Energy Efficiency: Direct vs Indirect Expansion

Direct expansion (DX) systems typically offer higher energy efficiency as the refrigerant directly cools the air or fluid, minimizing thermal losses compared to indirect expansion systems, which use an intermediate heat exchanger. Indirect expansion setups introduce additional components such as chilled water loops that can result in greater energy consumption due to pump operation and heat transfer inefficiencies. Optimizing energy efficiency in chilling technology relies on choosing DX systems for compact, precise cooling needs, while indirect systems suit larger installations requiring flexibility and multi-zone control.

Installation and Operational Costs Comparison

Direct Expansion (DX) systems generally have lower installation costs due to simpler equipment and fewer components compared to Indirect Expansion (IX) systems, which require additional heat exchangers and piping. Operational costs for DX systems can be higher in larger applications because the refrigerant directly cools the air or fluid, leading to greater energy consumption and maintenance demands, whereas IX systems offer improved efficiency and lower energy costs by utilizing separate chilled water loops. Selecting between DX and IX chilling technologies depends on application size, energy efficiency goals, and total cost of ownership considerations.

Performance and Temperature Control

Direct expansion (DX) systems offer superior temperature control and rapid cooling by circulating refrigerant directly through the evaporator coil, ensuring efficient heat exchange and precise temperature regulation. Indirect expansion systems use a secondary fluid, such as chilled water, which can introduce temperature gradients and slower response times, impacting overall performance. DX systems typically achieve higher energy efficiency in smaller cooling loads, while indirect expansion excels in large-scale or multi-zone applications requiring consistent temperature distribution.

Maintenance Requirements for DX and IX Systems

Direct Expansion (DX) systems require regular maintenance tasks such as coil cleaning, refrigerant level checks, and compressor inspections to prevent efficiency loss and refrigerant leaks. Indirect Expansion (IX) systems demand comprehensive upkeep involving secondary fluid monitoring, heat exchanger cleaning, and pump maintenance to ensure optimal thermal transfer and system reliability. Both systems benefit from proactive diagnostics, but IX systems often necessitate more frequent inspections due to the complexity of fluid circuits.

Best Applications for Direct and Indirect Expansion

Direct Expansion (DX) systems are best suited for small to medium-sized HVAC applications, such as residential buildings, retail spaces, and office environments, where precise temperature control and quick response times are essential. Indirect Expansion systems excel in large commercial or industrial chilling applications, including data centers, manufacturing plants, and hospitals, due to their enhanced efficiency, scalability, and ability to handle higher cooling loads while minimizing refrigerant exposure. Your choice between DX and indirect expansion depends on factors like system size, load variability, and energy efficiency requirements.

Choosing the Right Chiller Technology for Your Needs

Selecting between direct expansion and indirect expansion chillers depends on factors like system efficiency, installation space, and maintenance requirements. Direct expansion chillers use refrigerant to absorb heat directly from the chilled space, offering higher energy efficiency and simpler installation. Indirect expansion chillers circulate chilled water through a secondary loop, providing better temperature stability and flexibility for larger or complex HVAC systems.

Direct Expansion vs Indirect Expansion (chilling tech) Infographic

libmatt.com

libmatt.com