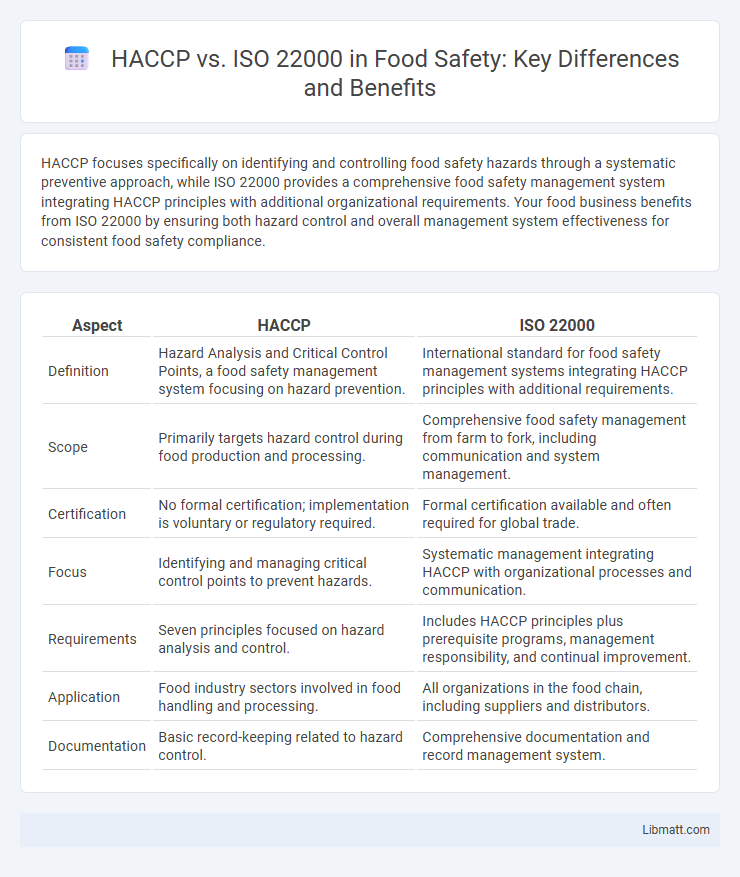

HACCP focuses specifically on identifying and controlling food safety hazards through a systematic preventive approach, while ISO 22000 provides a comprehensive food safety management system integrating HACCP principles with additional organizational requirements. Your food business benefits from ISO 22000 by ensuring both hazard control and overall management system effectiveness for consistent food safety compliance.

Table of Comparison

| Aspect | HACCP | ISO 22000 |

|---|---|---|

| Definition | Hazard Analysis and Critical Control Points, a food safety management system focusing on hazard prevention. | International standard for food safety management systems integrating HACCP principles with additional requirements. |

| Scope | Primarily targets hazard control during food production and processing. | Comprehensive food safety management from farm to fork, including communication and system management. |

| Certification | No formal certification; implementation is voluntary or regulatory required. | Formal certification available and often required for global trade. |

| Focus | Identifying and managing critical control points to prevent hazards. | Systematic management integrating HACCP with organizational processes and communication. |

| Requirements | Seven principles focused on hazard analysis and control. | Includes HACCP principles plus prerequisite programs, management responsibility, and continual improvement. |

| Application | Food industry sectors involved in food handling and processing. | All organizations in the food chain, including suppliers and distributors. |

| Documentation | Basic record-keeping related to hazard control. | Comprehensive documentation and record management system. |

Introduction to Food Safety Standards

HACCP (Hazard Analysis Critical Control Points) is a preventive, systematic approach focusing on identifying, evaluating, and controlling hazards in food production to ensure safety. ISO 22000 is an international standard that integrates HACCP principles within a broader food safety management system, incorporating requirement for communication, system management, and continuous improvement. Both frameworks aim to mitigate food safety risks, but ISO 22000 offers a comprehensive structure for organizations to manage food safety throughout the entire supply chain.

What is HACCP?

HACCP (Hazard Analysis and Critical Control Points) is a systematic preventive approach to food safety that identifies, evaluates, and controls physical, chemical, and biological hazards during production processes. It is a globally recognized standard designed to ensure food products are safe for consumption by focusing on critical control points within the supply chain. HACCP principles serve as the foundation for food safety management systems, including ISO 22000, which integrates HACCP with additional organizational requirements.

What is ISO 22000?

ISO 22000 is an international food safety management standard that integrates the principles of HACCP (Hazard Analysis and Critical Control Points) with a comprehensive management system framework. It helps organizations identify, control, and reduce food safety hazards throughout the food supply chain, ensuring compliance with regulatory requirements and consumer safety. Your implementation of ISO 22000 enhances food safety performance while meeting global market demands.

Core Principles of HACCP

HACCP is centered on seven core principles, including hazard analysis, identifying critical control points (CCPs), establishing critical limits, monitoring procedures, corrective actions, verification processes, and documentation. These principles ensure systematic prevention of food safety hazards during production. ISO 22000 incorporates HACCP principles within a broader food safety management system, integrating prerequisite programs and communication requirements for enhanced risk control.

Key Elements of ISO 22000

ISO 22000 integrates the principles of HACCP with a structured management system for food safety, emphasizing interactive communication, system management, and prerequisite programs. Key elements include a systematic approach to identifying hazards, establishing critical control points, and continuous monitoring throughout the supply chain. This standard also mandates clear documentation, management responsibility, resource management, and continual improvement to ensure food safety from farm to fork.

Similarities Between HACCP and ISO 22000

HACCP and ISO 22000 both prioritize identifying and controlling food safety hazards to ensure consumer protection. Both systems require documented procedures and continuous monitoring to maintain food safety standards throughout the supply chain. Integrated risk management and prerequisite programs, such as Good Manufacturing Practices (GMP), play essential roles in their frameworks for effective hazard prevention.

Major Differences: HACCP vs ISO 22000

HACCP (Hazard Analysis and Critical Control Points) focuses specifically on identifying and managing food safety hazards in production processes, while ISO 22000 offers a comprehensive food safety management system integrating HACCP principles with broader organizational requirements. Your choice between HACCP and ISO 22000 depends on whether you need a targeted hazard control plan or a full management system that includes communication, system management, and continual improvement. ISO 22000 also requires documented policies and procedures, making it more detailed and suitable for businesses seeking international certification and enhanced food safety culture.

Implementation Process: HACCP vs ISO 22000

HACCP implementation centers on identifying food safety hazards through seven principles, including hazard analysis, critical control points, limits, monitoring, corrective actions, verification, and documentation. ISO 22000 integrates the HACCP principles with a comprehensive food safety management system, requiring a detailed policy framework, management responsibility, resource allocation, communication, and continual improvement processes. The ISO 22000 implementation is broader, emphasizing organizational context and stakeholder engagement, whereas HACCP strictly targets hazard control within food production.

Benefits of Adopting Each Standard

Adopting HACCP enhances your food safety management by systematically identifying and controlling critical hazards, ensuring compliance with regulatory requirements and reducing foodborne risks. ISO 22000 offers a comprehensive food safety management system that integrates HACCP principles with broader organizational processes, promoting continual improvement and stronger stakeholder confidence. Both standards improve operational efficiency and product safety, but ISO 22000 provides a more holistic framework suitable for diverse food industry sectors.

Choosing the Right Standard for Your Business

Choosing the right standard for your business depends on your food safety management needs and regulatory requirements. HACCP focuses specifically on hazard analysis and critical control points, essential for identifying and controlling food safety risks. ISO 22000 offers a broader framework integrating HACCP principles with management system requirements, ideal for businesses seeking comprehensive food safety certification to enhance operational efficiency and customer confidence.

HACCP vs ISO 22000 Infographic

libmatt.com

libmatt.com