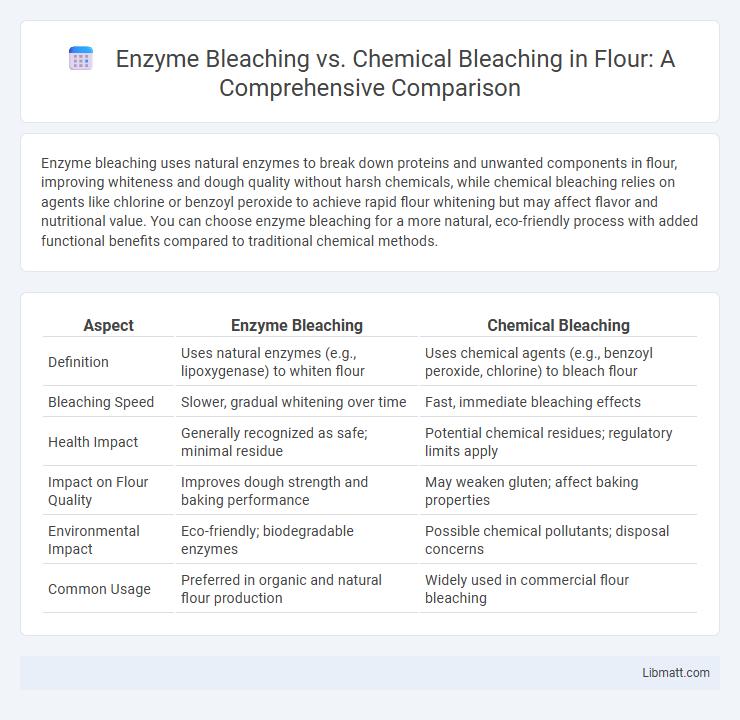

Enzyme bleaching uses natural enzymes to break down proteins and unwanted components in flour, improving whiteness and dough quality without harsh chemicals, while chemical bleaching relies on agents like chlorine or benzoyl peroxide to achieve rapid flour whitening but may affect flavor and nutritional value. You can choose enzyme bleaching for a more natural, eco-friendly process with added functional benefits compared to traditional chemical methods.

Table of Comparison

| Aspect | Enzyme Bleaching | Chemical Bleaching |

|---|---|---|

| Definition | Uses natural enzymes (e.g., lipoxygenase) to whiten flour | Uses chemical agents (e.g., benzoyl peroxide, chlorine) to bleach flour |

| Bleaching Speed | Slower, gradual whitening over time | Fast, immediate bleaching effects |

| Health Impact | Generally recognized as safe; minimal residue | Potential chemical residues; regulatory limits apply |

| Impact on Flour Quality | Improves dough strength and baking performance | May weaken gluten; affect baking properties |

| Environmental Impact | Eco-friendly; biodegradable enzymes | Possible chemical pollutants; disposal concerns |

| Common Usage | Preferred in organic and natural flour production | Widely used in commercial flour bleaching |

Introduction to Flour Bleaching Methods

Flour bleaching is a crucial process in baking that improves the flour's appearance and baking qualities by whitening the flour and enhancing its texture. Enzyme bleaching uses natural enzymes like peroxidase to accelerate oxidation, which gently whitens the flour without harsh chemicals. Chemical bleaching, on the other hand, involves agents such as benzoyl peroxide or chlorine dioxide that rapidly whiten flour but may impact nutritional content and flavor, influencing your baking outcomes.

What is Enzyme Bleaching?

Enzyme bleaching utilizes specific enzymes like amylases and lipases to break down impurities and pigments in flour, enhancing whiteness naturally without harsh chemicals. This process improves flour quality by preserving its nutritional content and functional properties, unlike traditional chemical bleaching agents such as benzoyl peroxide or chlorine gas. Enzyme bleaching is considered safer and eco-friendlier, reducing residual chemical presence in flour and resulting in a more natural, health-conscious product.

What is Chemical Bleaching?

Chemical bleaching in flour processing involves the use of oxidizing agents such as benzoyl peroxide or chlorine gas to whiten and improve the baking quality of flour by accelerating the aging process. These chemicals alter the pigment molecules, resulting in a brighter, more appealing flour color without affecting protein content significantly. You should note that chemical bleaching can impact the flavor and nutritional profile of the flour compared to natural aging or enzyme bleaching methods.

Key Differences Between Enzyme and Chemical Bleaching

Enzyme bleaching uses natural catalysts like amylase and xylanase to break down pigments in flour, resulting in a safer and more environmentally friendly process compared to chemical bleaching agents such as benzoyl peroxide and chlorine gas. Chemical bleaching alters flour color rapidly but may leave residues and affect nutritional quality, while enzyme bleaching improves dough properties and maintains flour's nutrient profile. Your choice depends on whether you prioritize speed and whiteness or sustainability and health benefits.

Advantages of Enzyme Bleaching for Flour

Enzyme bleaching in flour processing utilizes natural catalysts like lipoxygenase to break down pigments, resulting in brighter flour without producing harmful chemical residues. This method enhances flour quality by preserving nutritional content and improving dough handling properties compared to traditional chemical bleaching agents like benzoyl peroxide or chlorine gas. Enzyme bleaching also reduces environmental impact due to lower chemical use and safer byproducts, making it a sustainable alternative for flour refinement.

Benefits and Drawbacks of Chemical Bleaching

Chemical bleaching in flour enhances whiteness and improves baking consistency by breaking down carotenoids, offering a visually appealing product for consumers. However, this method may reduce some nutritional value, such as certain vitamins, and can leave chemical residues that concern health-conscious buyers. Your choice between chemical and enzyme bleaching depends on the balance you prioritize between appearance and natural processing.

Health and Safety Considerations

Enzyme bleaching in flour production uses natural catalysts that break down bran pigments without harmful chemicals, reducing respiratory and skin irritation risks for workers compared to chemical bleaching agents like benzoyl peroxide or chlorine dioxide. Chemical bleaching involves reactive substances that can produce harmful residues and pose inhalation hazards during processing, raising health and safety concerns in food manufacturing environments. Choosing enzyme bleaching enhances your facility's safety profile by minimizing exposure to toxic compounds, supporting healthier working conditions and safer end-products.

Environmental Impact of Bleaching Methods

Enzyme bleaching in flour processing significantly reduces environmental impact by minimizing the use of harsh chemicals and lowering water and energy consumption compared to chemical bleaching methods. Chemical bleaching agents like benzoyl peroxide and chlorine dioxide can lead to harmful byproducts and contribute to water pollution. Enzyme-based bleaching offers a biodegradable and eco-friendly alternative, promoting sustainable flour production with a reduced carbon footprint.

Consumer Preferences and Industry Trends

Enzyme bleaching in flour processing is gaining consumer preference due to its natural, eco-friendly profile, reducing the reliance on harsh chemicals commonly used in chemical bleaching. Industry trends reflect a shift toward sustainable practices, with enzyme bleaching offering improved flour quality and enhanced nutritional value while meeting growing demand for clean-label products. Your choice in flour products is increasingly influenced by these health-conscious trends and the preference for minimally processed ingredients.

Conclusion: Choosing the Best Flour Bleaching Method

Enzyme bleaching offers a more natural and eco-friendly approach to improving flour quality by breaking down pigments without compromising nutritional value, whereas chemical bleaching provides faster whitening but may involve synthetic additives. Your choice depends on prioritizing health considerations and environmental impact versus processing speed and cost-effectiveness. For higher-quality baked goods with a clean label, enzyme bleaching is increasingly preferred in the industry.

Enzyme Bleaching vs Chemical Bleaching (flour) Infographic

libmatt.com

libmatt.com