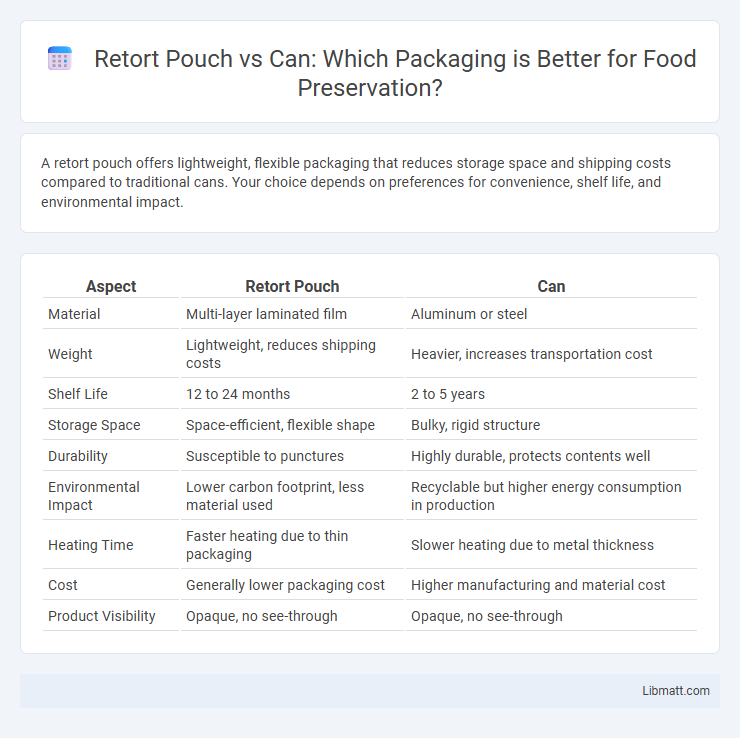

A retort pouch offers lightweight, flexible packaging that reduces storage space and shipping costs compared to traditional cans. Your choice depends on preferences for convenience, shelf life, and environmental impact.

Table of Comparison

| Aspect | Retort Pouch | Can |

|---|---|---|

| Material | Multi-layer laminated film | Aluminum or steel |

| Weight | Lightweight, reduces shipping costs | Heavier, increases transportation cost |

| Shelf Life | 12 to 24 months | 2 to 5 years |

| Storage Space | Space-efficient, flexible shape | Bulky, rigid structure |

| Durability | Susceptible to punctures | Highly durable, protects contents well |

| Environmental Impact | Lower carbon footprint, less material used | Recyclable but higher energy consumption in production |

| Heating Time | Faster heating due to thin packaging | Slower heating due to metal thickness |

| Cost | Generally lower packaging cost | Higher manufacturing and material cost |

| Product Visibility | Opaque, no see-through | Opaque, no see-through |

Introduction to Retort Pouch and Can Packaging

Retort pouches are flexible packaging made from multiple layers of plastic and metal foils, designed to withstand high-temperature sterilization, offering lightweight, space-saving alternatives to traditional cans. Cans are rigid metal containers, typically made of aluminum or steel, known for their durability, long shelf life, and ability to protect food from contamination and light. Both packaging types play crucial roles in food preservation, with retort pouches providing enhanced convenience and sustainability, while cans remain a robust choice for bulk storage.

Historical Development of Food Packaging Technologies

The evolution of food packaging technologies highlights the retort pouch as a significant advancement following the introduction of metal cans in the early 19th century. Metal cans, developed in the early 1800s, revolutionized food preservation by enabling airtight sealing and long shelf life, while retort pouches, emerging in the 1960s, combined flexible packaging with heat sterilization for lighter weight and improved convenience. This transition reflects continuous innovation aimed at enhancing food safety, portability, and sustainability in packaging materials.

Material Composition: Retort Pouch vs. Can

Retort pouches are composed of multiple layers including aluminum foil, polyester, and polypropylene, providing flexibility, lightweight properties, and excellent barrier protection against oxygen and moisture. In contrast, cans are typically made from aluminum or tin-plated steel, offering superior durability, rigidity, and resistance to physical damage but with increased weight and less flexibility. The multi-layered structure of retort pouches allows for more efficient heat transfer during sterilization compared to the metal enclosure of cans, impacting shelf stability and storage efficiency.

Shelf Life and Preservation Capabilities

Retort pouches offer a shelf life comparable to traditional cans, typically ranging from 12 to 24 months when properly sealed and stored. Their advanced heat sterilization process preserves food quality and nutrients effectively while maintaining a lightweight, flexible packaging form. Unlike cans, retort pouches resist corrosion and provide superior oxygen and light barrier properties, enhancing preservation capabilities and extending freshness.

Processing Methods: Sterilization and Safety

Retort pouches use advanced steam sterilization that preserves nutrients and flavor while ensuring microbial safety, making them ideal for heat-sensitive foods. Cans undergo high-temperature sterilization, providing robust microbial inactivation but often causing nutrient degradation and metallic taste issues. Your choice between retort pouch and can depends on balancing food safety requirements with texture and flavor retention.

Environmental Impact and Sustainability

Retort pouches have a significantly lower environmental impact compared to cans due to their lightweight design, which reduces transportation emissions and conserves raw materials. They require less energy to produce and generate less waste in landfills, as they occupy less space and are often recyclable depending on local facilities. Cans, while durable and recyclable, involve higher emissions during manufacture and transportation due to their heavier weight and metal extraction processes.

Cost Analysis: Production and Logistics

Retort pouches offer significant cost savings in production due to lower material usage and faster heat processing times compared to cans. Their lightweight design reduces shipping expenses and storage space requirements, enhancing overall logistical efficiency. Despite slightly higher packaging material costs, the combined reduction in transportation and warehousing costs makes retort pouches a more economical choice over traditional cans.

Consumer Convenience and Usability

Retort pouches offer superior consumer convenience due to their lightweight, flexible design, making them easier to carry, store, and open compared to traditional cans. These pouches also heat up faster and allow for resealing, enhancing usability for on-the-go lifestyles and portion control. Your choice between retort pouches and cans impacts meal preparation speed and storage flexibility, with pouches providing a modern solution for busy consumers.

Product Variety and Market Applications

Retort pouches offer a wide range of product variety, including ready-to-eat meals, soups, and beverages, catering to diverse market applications such as military, outdoor, and convenience foods. Cans are primarily used for beverages, canned fruits, vegetables, and preserved goods, excelling in long shelf life and durability for retail and bulk distribution. Your choice between retort pouches and cans depends on the specific packaging needs, market demands, and product types targeted.

Future Trends in Food Packaging Innovations

Retort pouches are increasingly favored for their lightweight, flexible design and superior heat transfer efficiency, which reduce cooking times and energy consumption compared to traditional cans. Advances in sustainable materials are driving a shift toward recyclable, bio-based films that enhance environmental benefits while maintaining shelf stability. Your choice of retort pouches or cans will hinge on evolving consumer demands for convenience, sustainability, and product freshness in future food packaging innovations.

retort pouch vs can Infographic

libmatt.com

libmatt.com