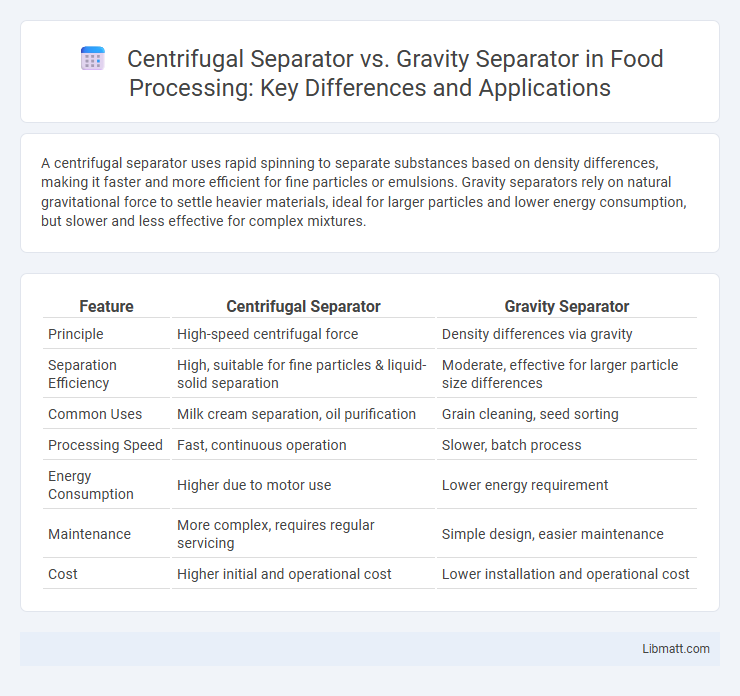

A centrifugal separator uses rapid spinning to separate substances based on density differences, making it faster and more efficient for fine particles or emulsions. Gravity separators rely on natural gravitational force to settle heavier materials, ideal for larger particles and lower energy consumption, but slower and less effective for complex mixtures.

Table of Comparison

| Feature | Centrifugal Separator | Gravity Separator |

|---|---|---|

| Principle | High-speed centrifugal force | Density differences via gravity |

| Separation Efficiency | High, suitable for fine particles & liquid-solid separation | Moderate, effective for larger particle size differences |

| Common Uses | Milk cream separation, oil purification | Grain cleaning, seed sorting |

| Processing Speed | Fast, continuous operation | Slower, batch process |

| Energy Consumption | Higher due to motor use | Lower energy requirement |

| Maintenance | More complex, requires regular servicing | Simple design, easier maintenance |

| Cost | Higher initial and operational cost | Lower installation and operational cost |

Introduction to Centrifugal and Gravity Separators

Centrifugal separators use high-speed rotational force to separate particles or liquids of different densities by accelerating the mixture in a circular motion, enabling rapid and precise separation. Gravity separators rely on the natural settling of particles based on density differences, allowing heavier materials to sink while lighter substances rise, typically requiring more time but offering energy-efficient processing. Both methods are essential in industries like food processing, wastewater treatment, and chemical manufacturing, where effective phase separation is critical.

Principles of Operation: Centrifugal vs. Gravity Separation

Centrifugal separators operate by rapidly spinning the mixture, using centrifugal force to separate particles based on density differences, which allows faster and more efficient separation of fine solids or immiscible liquids. Gravity separators rely on the natural settling process, where heavier particles sink due to gravity while lighter ones remain suspended or float, making them suitable for coarse or larger particles with slower separation rates. Your choice between centrifugal and gravity separation depends on the desired efficiency, particle size, and separation speed required for your application.

Key Applications in Industry

Centrifugal separators are widely used in industries such as chemical processing, wastewater treatment, and food production to efficiently separate fine solids from liquids or immiscible liquids based on density differences. Gravity separators find key applications in mineral processing, agriculture, and recycling, where slower separation of heavier particles from lighter materials is required, often in grain cleaning and ore beneficiation. Both separators optimize separation efficiency by leveraging density contrasts, but centrifugal separators excel in high-throughput, fine-particle, and rapid separation tasks.

Efficiency Comparison: Speed and Purity

Centrifugal separators achieve higher efficiency by rapidly spinning at thousands of RPMs, enabling faster phase separation and producing purer outputs compared to gravity separators. Gravity separators rely on natural density differences, resulting in slower separation speeds and lower purity levels, especially for fine or emulsified mixtures. Industrial applications demanding high throughput and maximum purity typically prefer centrifugal separation due to its superior speed and effective phase distinction.

Equipment Design and Maintenance

Centrifugal separators feature high-speed rotating components that exert centrifugal force to separate particles, requiring precise engineering and regular maintenance of bearings, seals, and rotors to ensure optimal performance. Gravity separators rely on differences in specific gravity for separation, typically involving simpler equipment design with fewer moving parts, which reduces maintenance frequency but demands careful calibration of feed rates and fluid flow. Your choice between these separators depends on the balance between maintenance complexity and equipment durability tailored to your operational needs.

Energy Consumption and Operational Costs

Centrifugal separators consume significantly more energy than gravity separators due to their high-speed rotation mechanisms, leading to increased operational costs in large-scale applications. Gravity separators rely on natural gravitational forces, resulting in minimal energy use and lower maintenance expenses. Choosing between these technologies depends on balancing separation efficiency with energy consumption and overall cost-effectiveness for specific industrial processes.

Suitability for Different Materials

Centrifugal separators excel in processing fine particles, emulsions, and liquids with varying densities, making them highly suitable for mixtures like oil-water suspensions and fine solids in liquids. Gravity separators are ideal for coarse and heavy particles, commonly used in mineral processing and wastewater treatment where density differences are pronounced. Material properties such as particle size, density, and liquid viscosity determine the choice between centrifugal and gravity separation methods for optimal efficiency.

Space and Installation Requirements

Centrifugal separators require more space due to their larger size and complex installation needs, including stable foundations and access for maintenance. Gravity separators have minimal space and installation requirements, making them ideal for compact facilities and simpler setups. Your choice depends on available space and installation constraints at your site.

Environmental Impact and Sustainability

Centrifugal separators offer higher efficiency in separating contaminants, reducing waste discharge and minimizing environmental pollution compared to gravity separators, which rely on slower natural settling processes. Your choice of a centrifugal separator can lead to lower energy consumption due to faster processing times and reduced chemical usage, enhancing overall sustainability. Gravity separators tend to have a smaller carbon footprint in low-volume applications but may require more land and water resources, impacting long-term environmental management.

Choosing the Right Separator for Your Needs

Centrifugal separators use high-speed rotation to effectively separate particles based on density, making them ideal for applications requiring fast and precise separation of fine or emulsified substances. Gravity separators rely on natural settling by density differences and are best suited for larger particles and lower flow rates where gentle separation is sufficient. Selecting the right separator depends on factors such as particle size, separation speed, fluid viscosity, and operational scale to optimize efficiency and product purity.

centrifugal separator vs gravity separator Infographic

libmatt.com

libmatt.com