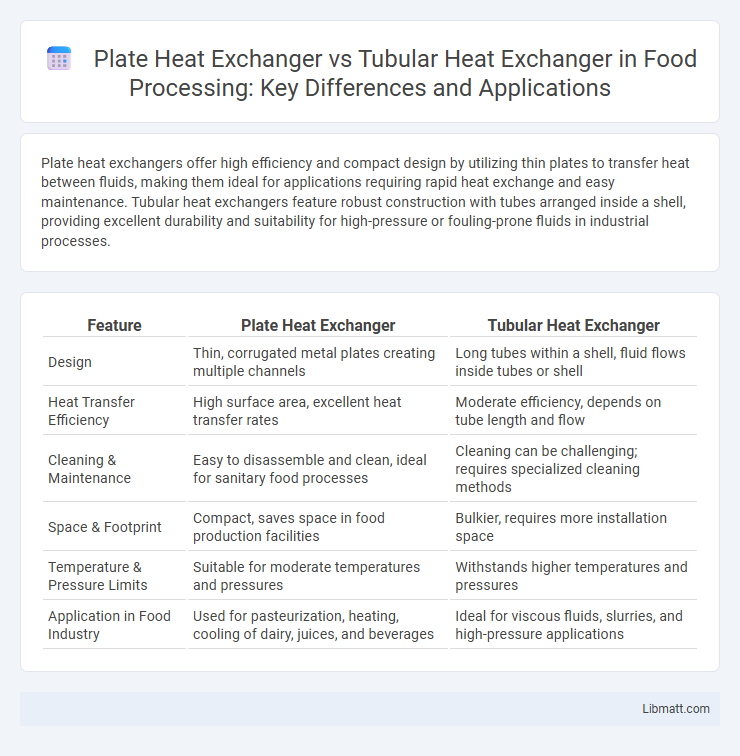

Plate heat exchangers offer high efficiency and compact design by utilizing thin plates to transfer heat between fluids, making them ideal for applications requiring rapid heat exchange and easy maintenance. Tubular heat exchangers feature robust construction with tubes arranged inside a shell, providing excellent durability and suitability for high-pressure or fouling-prone fluids in industrial processes.

Table of Comparison

| Feature | Plate Heat Exchanger | Tubular Heat Exchanger |

|---|---|---|

| Design | Thin, corrugated metal plates creating multiple channels | Long tubes within a shell, fluid flows inside tubes or shell |

| Heat Transfer Efficiency | High surface area, excellent heat transfer rates | Moderate efficiency, depends on tube length and flow |

| Cleaning & Maintenance | Easy to disassemble and clean, ideal for sanitary food processes | Cleaning can be challenging; requires specialized cleaning methods |

| Space & Footprint | Compact, saves space in food production facilities | Bulkier, requires more installation space |

| Temperature & Pressure Limits | Suitable for moderate temperatures and pressures | Withstands higher temperatures and pressures |

| Application in Food Industry | Used for pasteurization, heating, cooling of dairy, juices, and beverages | Ideal for viscous fluids, slurries, and high-pressure applications |

Introduction to Plate and Tubular Heat Exchangers

Plate heat exchangers consist of multiple thin, corrugated metal plates that create a large surface area for heat transfer, making them highly efficient in compact spaces. Tubular heat exchangers use concentric or parallel tubes to transfer heat, offering durability and suitability for handling high-pressure and high-temperature fluids. Understanding the design differences helps you choose the right exchanger based on thermal performance and application requirements.

Basic Working Principles

Plate heat exchangers operate by passing fluids through a series of thin, corrugated metal plates that create large surface areas for efficient heat transfer, allowing fluids to flow in alternating channels. Tubular heat exchangers function by circulating one fluid through a bundle of tubes while the other fluid flows externally around the tubes, enabling heat exchange through the tube walls. Understanding these basic working principles helps you select the optimal heat exchanger based on your application's thermal performance and maintenance requirements.

Design Differences

Plate heat exchangers feature thin, corrugated metal plates stacked together, creating a large surface area for efficient heat transfer and compact design, while tubular heat exchangers consist of one or more tubes enclosed within a shell, allowing fluid to flow inside the tubes and another fluid outside. Plate heat exchangers provide easier cleaning and maintenance due to their removable plates, whereas tubular heat exchangers excel in handling high-pressure and high-temperature applications with robust, tubular construction. The design differences influence fluid flow patterns, heat transfer efficiency, and suitability for specific industrial processes such as HVAC, chemical processing, and power generation.

Heat Transfer Efficiency Comparison

Plate heat exchangers offer significantly higher heat transfer efficiency due to their large surface area and turbulent flow paths, promoting rapid thermal exchange. Tubular heat exchangers exhibit lower efficiency as their design limits surface area contact and generally supports laminar flow, reducing overall heat transfer rates. Your choice between these models should consider the specific thermal performance requirements and space constraints in your system.

Space and Footprint Requirements

Plate heat exchangers offer a compact design, enabling significant space and footprint savings compared to tubular heat exchangers. Their thin, corrugated plates provide a large surface area for heat transfer within a smaller volume, making them ideal for installations with limited space. You can optimize your facility layout by choosing plate heat exchangers when reducing equipment footprint is a priority.

Maintenance and Cleaning Considerations

Plate heat exchangers feature removable plates, allowing easy access for thorough cleaning and maintenance, which reduces downtime and operational costs. Tubular heat exchangers require specialized tools and more labor-intensive procedures to clean internal tubes, making maintenance more complex and time-consuming. Your choice should consider the frequency of cleaning needs and the available maintenance resources to ensure optimal performance.

Suitability for Different Applications

Plate heat exchangers offer high heat transfer efficiency and compact design, making them suitable for applications like HVAC systems, food processing, and pharmaceuticals where space and rapid temperature changes are critical. Tubular heat exchangers excel in handling high-pressure, high-temperature fluids and are ideal for industries such as chemical processing, oil refineries, and power plants that require robust performance under harsh conditions. Your choice depends on the specific operational demands, including fluid viscosity, cleanliness, and maintenance requirements.

Cost Comparison and Economic Considerations

Plate heat exchangers generally offer lower initial costs and higher thermal efficiency, making them more economical for applications requiring compact design and frequent cleaning. Tubular heat exchangers tend to have higher upfront costs but excel in handling high pressures, fouling fluids, and thermal stresses, providing long-term reliability in demanding environments. Your choice influences operational expenses and maintenance costs, with plate units favoring energy savings and tubular designs offering durability for specialized industrial processes.

Durability and Material Choices

Plate heat exchangers typically feature corrosive-resistant stainless steel or titanium plates, providing high durability and efficient heat transfer in clean or mildly contaminated fluids. Tubular heat exchangers use robust materials such as carbon steel or alloy tubes, offering superior resistance to fouling, high pressure, and abrasive or corrosive fluids, making them ideal for harsh industrial environments. Material selection directly impacts longevity, with tubular designs excelling in durability for aggressive applications, while plate heat exchangers balance efficiency and resistance for moderate conditions.

Environmental and Energy Efficiency Factors

Plate heat exchangers offer superior energy efficiency due to their high heat transfer surface area and compact design, reducing energy consumption and greenhouse gas emissions. Tubular heat exchangers, while durable for high-pressure applications, often have lower thermal efficiency and higher fluid volume, leading to increased energy use. Choosing a plate heat exchanger can enhance your system's environmental sustainability by minimizing energy waste and optimizing heat recovery.

plate heat exchanger vs tubular heat exchanger Infographic

libmatt.com

libmatt.com