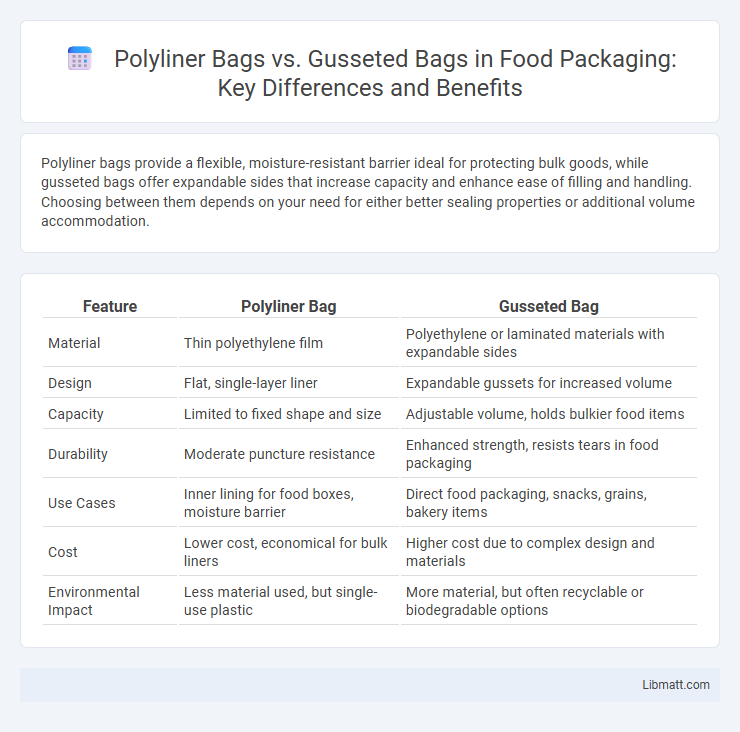

Polyliner bags provide a flexible, moisture-resistant barrier ideal for protecting bulk goods, while gusseted bags offer expandable sides that increase capacity and enhance ease of filling and handling. Choosing between them depends on your need for either better sealing properties or additional volume accommodation.

Table of Comparison

| Feature | Polyliner Bag | Gusseted Bag |

|---|---|---|

| Material | Thin polyethylene film | Polyethylene or laminated materials with expandable sides |

| Design | Flat, single-layer liner | Expandable gussets for increased volume |

| Capacity | Limited to fixed shape and size | Adjustable volume, holds bulkier food items |

| Durability | Moderate puncture resistance | Enhanced strength, resists tears in food packaging |

| Use Cases | Inner lining for food boxes, moisture barrier | Direct food packaging, snacks, grains, bakery items |

| Cost | Lower cost, economical for bulk liners | Higher cost due to complex design and materials |

| Environmental Impact | Less material used, but single-use plastic | More material, but often recyclable or biodegradable options |

Introduction to Polyliner Bags and Gusseted Bags

Polyliner bags are typically smooth, flexible liners designed to fit inside containers and provide a moisture-resistant barrier, enhancing product protection through a seamless interior. Gusseted bags feature expandable side panels that increase capacity and allow the bag to stand upright, improving storage efficiency and ease of handling. Your choice between polyliner and gusseted bags depends on whether you prioritize a tight moisture seal or greater volume and stability in packaging.

Key Features of Polyliner Bags

Polyliner bags are designed with waterproof, durable polyethylene material that provides superior moisture resistance and protection for stored goods. Their seamless, flexible construction allows for easy lining of bulk containers and pallets, enhancing sanitary conditions and preventing product contamination. Unlike gusseted bags, polyliner bags offer a smooth interior surface that optimizes space utilization and simplifies filling and emptying processes.

Key Features of Gusseted Bags

Gusseted bags feature expandable side panels that increase capacity and allow efficient storage of bulkier items, making them ideal for versatile packaging needs. Their reinforced seams provide enhanced durability and better weight distribution compared to standard polyliner bags, which typically lack these structural benefits. The ability of gusseted bags to stand upright improves product visibility and shelf appeal, distinguishing them in retail environments.

Material Composition and Durability

Polyliner bags are typically made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), providing excellent moisture resistance and flexibility, making them ideal for protecting contents from external elements. Gusseted bags, on the other hand, often utilize thicker materials such as kraft paper, laminated films, or woven polypropylene, enhancing their structural strength and durability for heavier or bulkier items. Your choice depends on whether you prioritize lightweight moisture protection with polyliners or robust load-bearing capacity with gusseted bags.

Storage Capacity and Space Efficiency

Polyliner bags offer a flexible storage solution with a conforming shape that maximizes use of irregular container spaces, making them ideal for bulk storage with minimal air pockets. Gusseted bags feature expandable side folds that increase volume capacity and optimize stacking efficiency, enhancing space utilization in both storage and transport. The choice between polyliner and gusseted bags depends on the specific storage needs, balancing flexibility versus structured capacity for optimal space efficiency.

Common Applications in Various Industries

Polyliner bags are commonly used in food packaging, agriculture, and chemical industries due to their moisture resistance and flexibility, making them ideal for protecting products like grains, powders, and liquids. Gusseted bags find widespread applications in retail, pharmaceuticals, and manufacturing, providing extra capacity and structural support for bulkier or heavier items such as snacks, pharmaceuticals, and hardware components. Your choice between these bags depends on the specific product requirements and the level of protection and durability needed in various industrial settings.

Cost Comparison: Polyliner vs Gusseted Bags

Polyliner bags generally offer a lower cost per unit compared to gusseted bags due to their simpler design and manufacturing process, making them a budget-friendly option for bulk packaging. Gusseted bags provide better volume capacity and structural integrity, which can lead to reduced product damage and overall savings despite their higher upfront cost. Your choice depends on balancing initial investment against long-term efficiency and protection needs.

Customization and Printing Options

Polyliner bags offer limited customization, typically featuring standard printing options suitable for basic branding needs, while gusseted bags provide extensive customization with vibrant, multi-color printing capabilities and various finishes for enhanced brand visibility. Your choice should consider the level of design detail and color complexity required to effectively communicate your brand message. Gusseted bags allow for adjustments in size and shape to better accommodate product volume, offering more flexibility in personalized branding.

Environmental Impact and Sustainability

Polyliner bags generally have a higher environmental impact due to their reliance on non-biodegradable polyethylene, contributing to long-term plastic waste. Gusseted bags, often made from paper or biodegradable materials, offer better sustainability by decomposing more rapidly and supporting recycling efforts. Your choice of gusseted bags can significantly reduce carbon footprint and enhance eco-friendly packaging solutions.

Choosing the Right Bag for Your Needs

Polyliner bags offer excellent moisture resistance and airtight sealing, making them ideal for products requiring protection from humidity and contamination. Gusseted bags provide expanded capacity and improved shape, allowing for easier packing and enhanced stability during transport and storage. Selecting between a polyliner bag and a gusseted bag depends on whether your priority is moisture protection or maximizing volume and packaging efficiency.

polyliner bag vs gusseted bag Infographic

libmatt.com

libmatt.com