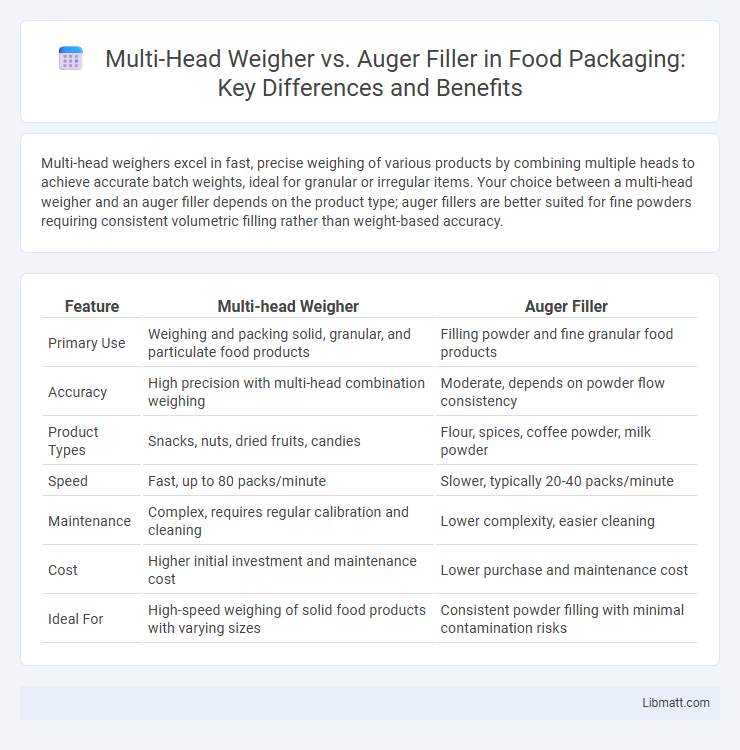

Multi-head weighers excel in fast, precise weighing of various products by combining multiple heads to achieve accurate batch weights, ideal for granular or irregular items. Your choice between a multi-head weigher and an auger filler depends on the product type; auger fillers are better suited for fine powders requiring consistent volumetric filling rather than weight-based accuracy.

Table of Comparison

| Feature | Multi-head Weigher | Auger Filler |

|---|---|---|

| Primary Use | Weighing and packing solid, granular, and particulate food products | Filling powder and fine granular food products |

| Accuracy | High precision with multi-head combination weighing | Moderate, depends on powder flow consistency |

| Product Types | Snacks, nuts, dried fruits, candies | Flour, spices, coffee powder, milk powder |

| Speed | Fast, up to 80 packs/minute | Slower, typically 20-40 packs/minute |

| Maintenance | Complex, requires regular calibration and cleaning | Lower complexity, easier cleaning |

| Cost | Higher initial investment and maintenance cost | Lower purchase and maintenance cost |

| Ideal For | High-speed weighing of solid food products with varying sizes | Consistent powder filling with minimal contamination risks |

Introduction to Multi-head Weighers and Auger Fillers

Multi-head weighers use multiple weighing heads to achieve highly accurate and fast portioning by combining weights from each head, ideal for granular and solid products. Auger fillers utilize a rotating screw within a tube to dispense precise volumes of powders and fine granules, offering consistent filling for free-flowing powders. Both machines optimize packaging efficiency but cater to different product types based on their weighing and filling methods.

How Multi-head Weighers Work

Multi-head weighers operate by using multiple weighing heads to simultaneously measure product portions, delivering accurate weight distribution for packaging. Each head collects a small quantity of the product and the system's computer swiftly calculates the best combination of heads to match the target weight. This process ensures high-speed, precise weighing ideal for granular or small pieces in food and industrial packaging applications.

How Auger Fillers Operate

Auger fillers operate by using a rotating screw to dispense precise amounts of powder or granular products into packaging, ensuring consistent weight control. This mechanism allows for accurate portioning, particularly beneficial for fine or free-flowing powders where the product flow needs to be carefully regulated. Compared to multi-head weighers, auger fillers are ideal for products that require volumetric or weight-based filling with minimal product degradation.

Key Differences Between Multi-head Weighers and Auger Fillers

Multi-head weighers use multiple weighing heads to rapidly and accurately measure product portions, making them ideal for granular or solid items like snacks and nuts. Auger fillers rely on a rotating screw mechanism to dispense precise volumes of powdery or fine materials such as flour or spices, ensuring consistent fill levels. You should choose a multi-head weigher for speed and versatility with irregular shapes, while auger fillers excel in handling powders with minimal product degradation.

Accuracy and Consistency Comparison

Multi-head weighers deliver superior accuracy by combining multiple weigh heads that simultaneously measure product portions, ensuring consistent and precise weight targets even with irregularly shaped items. Auger fillers, which use a rotating screw to dispense powder or granular products, may experience variability due to fluctuations in product density and flow rate, potentially reducing consistency. Choosing a multi-head weigher enhances your packaging reliability through precise portion control, minimizing product giveaway and ensuring uniform package weights.

Suitable Product Types for Each Filler

Multi-head weighers are ideal for handling granular and small-sized products such as snacks, nuts, and candies, ensuring high-speed and accurate portion control. Auger fillers excel with fine powders like flour, spices, and pharmaceutical powders, providing precise volumetric filling without product degradation. Your choice depends on the product's physical characteristics, with multi-head weighers suited for free-flowing solids and auger fillers for free-flowing to slightly cohesive powders.

Speed and Efficiency Analysis

Multi-head weighers excel in high-speed packaging environments by simultaneously weighing multiple portions, significantly increasing throughput and reducing cycle times compared to auger fillers. Auger fillers, while precise for powder and granular products, generally operate at slower speeds due to their single-fill mechanism and need for product settling between fills. Your choice between these systems should consider the volume and speed requirements of your production line to maximize efficiency and maintain consistent accuracy.

Maintenance and Operational Costs

Multi-head weighers typically require more complex maintenance due to numerous moving parts and electronic components, which can increase operational costs over time. Auger fillers have simpler mechanisms and fewer parts, resulting in reduced downtime and lower maintenance expenses. Your choice between the two should consider long-term cost efficiency and ease of servicing to optimize overall productivity.

Industry Applications and Use Cases

Multi-head weighers excel in the packaging of granular and snack products due to their high-speed and high-accuracy multi-point weighing system, ideal for food industries requiring precise portion control like nuts, candies, and frozen vegetables. Auger fillers are predominantly utilized in the pharmaceutical and chemical industries for dispensing powders and fine granules with consistent volumetric output, making them suitable for applications like powdered spices, detergents, and pharmaceuticals. The choice between these machines depends on product type, required filling speed, and dosing accuracy critical to specific industrial applications.

Choosing the Right Filler for Your Packaging Needs

Multi-head weighers offer precise, fast weighing of granular and particulate products, making them ideal for items like snacks, nuts, and frozen foods requiring accurate portion control. Auger fillers excel in dispensing powdered or fine materials such as flour, spices, or powdered chemicals, ensuring consistent fill volumes through controlled screw rotation. Understanding your product's texture and packaging speed requirements helps you choose the right filler that maximizes efficiency and maintains your product quality.

Multi-head Weigher vs Auger Filler Infographic

libmatt.com

libmatt.com