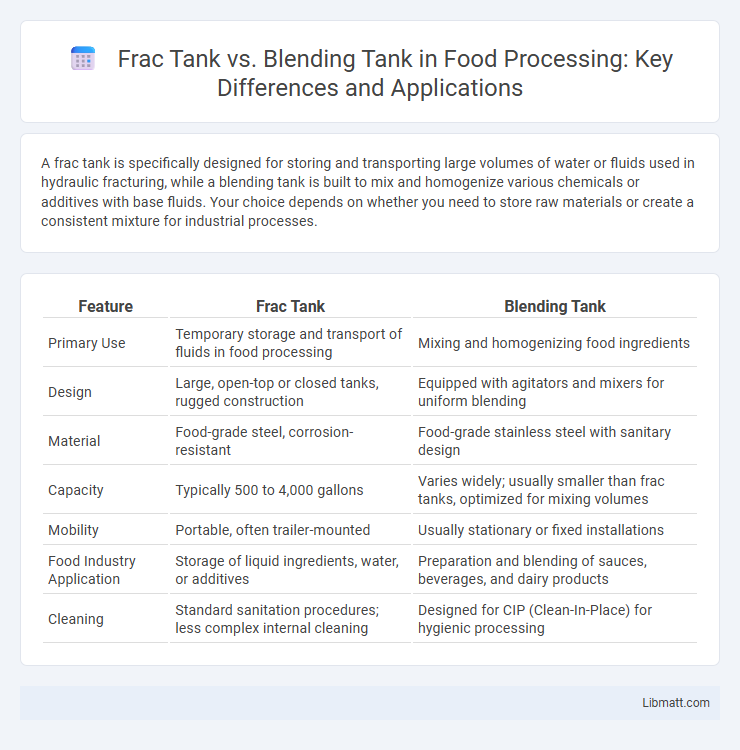

A frac tank is specifically designed for storing and transporting large volumes of water or fluids used in hydraulic fracturing, while a blending tank is built to mix and homogenize various chemicals or additives with base fluids. Your choice depends on whether you need to store raw materials or create a consistent mixture for industrial processes.

Table of Comparison

| Feature | Frac Tank | Blending Tank |

|---|---|---|

| Primary Use | Temporary storage and transport of fluids in food processing | Mixing and homogenizing food ingredients |

| Design | Large, open-top or closed tanks, rugged construction | Equipped with agitators and mixers for uniform blending |

| Material | Food-grade steel, corrosion-resistant | Food-grade stainless steel with sanitary design |

| Capacity | Typically 500 to 4,000 gallons | Varies widely; usually smaller than frac tanks, optimized for mixing volumes |

| Mobility | Portable, often trailer-mounted | Usually stationary or fixed installations |

| Food Industry Application | Storage of liquid ingredients, water, or additives | Preparation and blending of sauces, beverages, and dairy products |

| Cleaning | Standard sanitation procedures; less complex internal cleaning | Designed for CIP (Clean-In-Place) for hygienic processing |

Introduction to Frac Tanks and Blending Tanks

Frac tanks are large, portable steel containers primarily used for storing and transporting water, chemicals, and drilling fluids on oil and gas sites. Blending tanks are specialized vessels designed to mix and homogenize multiple fluid components, such as chemicals and water, ensuring a consistent solution for hydraulic fracturing operations. Both tanks are essential in the oilfield industry but serve distinct functions related to fluid storage and preparation.

Definition and Primary Functions

A frac tank is a specialized container designed primarily for the temporary storage and transportation of fluids during hydraulic fracturing operations, ensuring efficient containment of water, oil, or drilling fluids. Blending tanks are engineered to mix and homogenize various liquid components, such as chemicals and additives, to create precise fluid formulations essential for industrial or frac fluid preparation. Understanding the distinct roles of frac tanks and blending tanks helps optimize fluid management and operational efficiency in your oilfield or industrial processes.

Key Design Differences

Frac tanks feature robust, rectangular steel construction designed for temporary storage of large volumes of water or fluids on drilling sites, emphasizing portability and durability. Blending tanks incorporate agitators and specialized internal baffles to ensure consistent mixing of chemicals and fluids, optimizing chemical blending processes. Your choice depends on whether you need high-capacity storage with easy transport (frac tank) or precise mixing capabilities for fluid management (blending tank).

Common Industrial Applications

Frac tanks and blending tanks serve distinct roles in industrial applications, with frac tanks primarily used for temporary storage and transportation of liquids like water, oil, or chemicals on drilling sites. Blending tanks are designed for mixing multiple fluids to achieve a homogeneous solution, common in chemical processing, wastewater treatment, and paint manufacturing. Your choice depends on whether the priority is bulk storage and mobility or precise fluid mixing and chemical consistency.

Material Compatibility and Storage Capacity

Frac tanks are typically made of carbon steel with corrosion-resistant coatings, ensuring compatibility with a range of hydraulic fracturing fluids, while blending tanks often utilize stainless steel or specialized linings to handle aggressive chemicals and maintain material purity. Storage capacity varies as frac tanks generally offer larger volumes, often ranging from 6,000 to 12,000 gallons, suited for bulk fluid storage, whereas blending tanks are designed with smaller capacities, typically between 500 and 3,000 gallons, optimized for precise mixing and chemical blending operations. Selecting between the two depends on the specific chemical properties of the stored fluids and the volume requirements of the project.

Mobility and Deployment

Frac tanks offer superior mobility with rugged wheels and heavy-duty frames designed for easy transportation to remote drilling sites. Blending tanks prioritize on-site customization but typically require more complex setup and less frequent relocation due to their integrated mixing systems. Your project's efficiency depends on choosing a tank that balances quick deployment with operational flexibility.

Operational Efficiency and Cost Considerations

Frac tanks offer superior operational efficiency for large-scale fluid storage and quick deployment in oilfield services, reducing downtime during hydraulic fracturing operations. Blending tanks optimize chemical mixing processes, ensuring precise formulation that minimizes material waste and enhances overall project cost-effectiveness. You can achieve significant cost savings by selecting the appropriate tank type based on your storage volume needs and process integration requirements.

Safety Features and Environmental Impact

Frac tanks feature reinforced steel walls and secure manways to prevent leaks and withstand high pressure, minimizing the risk of hazardous spills during hydraulic fracturing. Blending tanks incorporate automated mixing systems with secondary containment to control chemical reactions and contain potential runoff, enhancing operational safety and environmental compliance. Both tank types are designed with corrosion-resistant coatings and grounding systems to reduce environmental contamination and prevent static discharge incidents.

Choosing the Right Tank for Your Operation

Selecting the appropriate tank for your operation depends on the specific requirements of fluid handling and storage. Frac tanks, designed for high-volume water storage and transport in hydraulic fracturing, offer durability and large capacity ideal for rugged field conditions. Blending tanks, optimized for mixing chemicals and precise formulation, provide integrated agitation systems crucial for creating consistent fluid blends in industrial or agricultural applications.

Summary and Industry Best Practices

Frac tanks and blending tanks serve distinct roles in industrial fluid management, with frac tanks designed primarily for storing and transporting large volumes of water or chemicals used in hydraulic fracturing, while blending tanks are specialized for mixing precise chemical formulations to optimize fluid properties. Industry best practices emphasize regular inspection and proper cleaning of frac tanks to prevent contamination, combined with accurate instrumentation and automated controls in blending tanks to ensure consistent chemical concentrations. Selecting the appropriate tank depends on project requirements, with frac tanks favored for bulk storage and blending tanks critical for achieving precise fluid compositions in oilfield operations.

frac tank vs blending tank Infographic

libmatt.com

libmatt.com