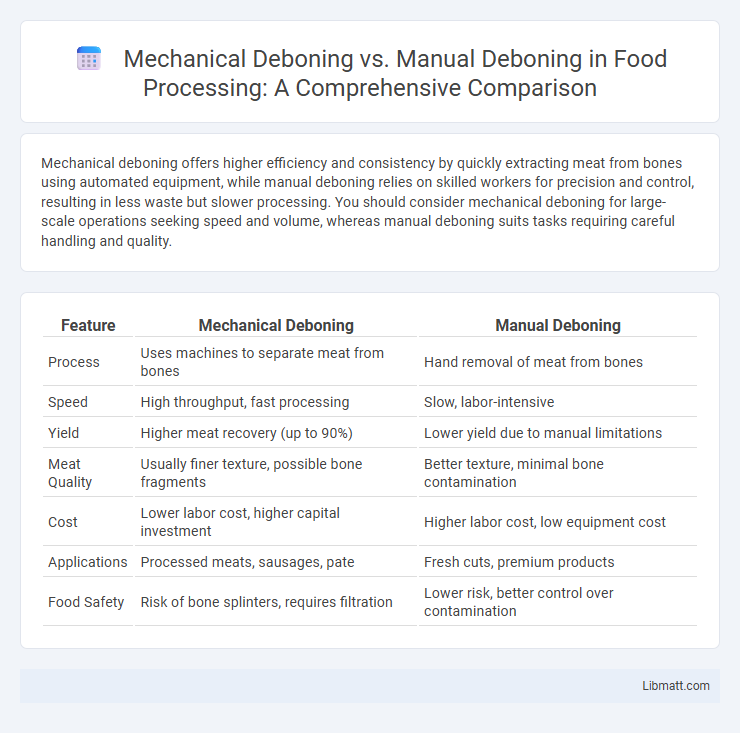

Mechanical deboning offers higher efficiency and consistency by quickly extracting meat from bones using automated equipment, while manual deboning relies on skilled workers for precision and control, resulting in less waste but slower processing. You should consider mechanical deboning for large-scale operations seeking speed and volume, whereas manual deboning suits tasks requiring careful handling and quality.

Table of Comparison

| Feature | Mechanical Deboning | Manual Deboning |

|---|---|---|

| Process | Uses machines to separate meat from bones | Hand removal of meat from bones |

| Speed | High throughput, fast processing | Slow, labor-intensive |

| Yield | Higher meat recovery (up to 90%) | Lower yield due to manual limitations |

| Meat Quality | Usually finer texture, possible bone fragments | Better texture, minimal bone contamination |

| Cost | Lower labor cost, higher capital investment | Higher labor cost, low equipment cost |

| Applications | Processed meats, sausages, pate | Fresh cuts, premium products |

| Food Safety | Risk of bone splinters, requires filtration | Lower risk, better control over contamination |

Introduction to Deboning Methods

Mechanical deboning uses specialized machines to quickly separate meat from bones, increasing yield and efficiency in meat processing industries. Manual deboning involves skilled workers carefully removing meat by hand, preserving texture and minimizing damage to the meat fibers. Your choice between these methods depends on factors like production scale, desired meat quality, and cost considerations.

What is Mechanical Deboning?

Mechanical deboning is an automated process that separates meat from bones using specialized machinery, increasing efficiency and yield compared to manual deboning. This method utilizes pressure and blades to extract residual meat, making it ideal for processing poultry and other small carcasses. Your production line can benefit from mechanical deboning by reducing labor costs and maximizing meat recovery while maintaining consistent product quality.

What is Manual Deboning?

Manual deboning is the process of removing meat from bones by hand, using knives and other handheld tools to carefully separate muscle tissue. This technique ensures higher meat quality and less damage to the texture compared to mechanical deboning, which uses machines to extract meat and often results in higher fat and bone particle content. Choosing manual deboning allows you to maintain better control over product consistency and hygiene standards in meat processing.

Efficiency Comparison: Mechanical vs. Manual

Mechanical deboning significantly boosts processing efficiency by rapidly extracting meat from bones at speeds up to 8 times faster than manual deboning. Automated systems reduce labor costs and minimize physical strain on workers, leading to increased throughput and consistency in meat yield. Manual deboning, while slower and more labor-intensive, offers higher precision for delicate cuts but cannot match the output volume achieved by mechanical deboning technologies.

Product Quality and Yield Differences

Mechanical deboning significantly increases yield by recovering more meat from bones compared to manual deboning, which is labor-intensive and results in lower yield. However, mechanical deboned meat often has a finer texture and may contain higher bone fragments and calcium levels, impacting product quality and limiting its use in certain applications. Your choice depends on prioritizing higher yield with potential quality trade-offs or superior meat texture with reduced quantity.

Food Safety Considerations

Mechanical deboning increases the risk of bacterial contamination due to higher surface area exposure and temperature rise during processing, necessitating stringent sanitation protocols. Manual deboning allows better control over contamination sources by minimizing tissue damage and cross-contact but is more labor-intensive and slower. Your choice between these methods should consider the balance between processing speed and maintaining stringent food safety standards.

Cost Implications and Labor Needs

Mechanical deboning significantly reduces labor costs by automating the separation of meat from bones, increasing throughput and consistency compared to manual deboning. The initial investment in mechanical deboning equipment is high but results in lower ongoing labor expenses and faster processing times. Manual deboning requires skilled labor, higher wages, and longer processing durations, making it costlier and less efficient for large-scale production.

Impact on Texture and Appearance

Mechanical deboning produces finer meat texture with less visible muscle structure, often resulting in a paste-like consistency ideal for processed products but less appealing in whole cuts. Manual deboning preserves the natural grain and firmness of the meat, maintaining superior texture and a more visually appealing appearance preferred in premium cuts and culinary presentations. Texture and appearance differences directly influence product quality perception and suitability for various food applications.

Common Uses and Industry Preferences

Mechanical deboning is widely used in large-scale poultry and meat processing plants due to its efficiency in extracting maximum meat from bones, especially for products like sausages, nuggets, and processed meats. Manual deboning remains preferred in premium restaurants and specialty markets where precise cuts and minimal meat damage are critical for quality and presentation. Your choice between these methods depends on production scale, desired product texture, and industry standards for food quality.

Future Trends in Deboning Technology

Mechanical deboning technology is rapidly advancing with innovations in automation, AI-driven robotics, and improved meat recovery rates, making it more efficient and cost-effective than manual deboning. Emerging trends include the integration of sensor-based quality control, which ensures higher accuracy and reduces contamination risks compared to traditional manual methods. Future developments prioritize sustainability and precision, enabling processors to maximize yield while maintaining product quality and meeting increasing consumer demand for traceable and minimally processed meat products.

mechanical deboning vs manual deboning Infographic

libmatt.com

libmatt.com