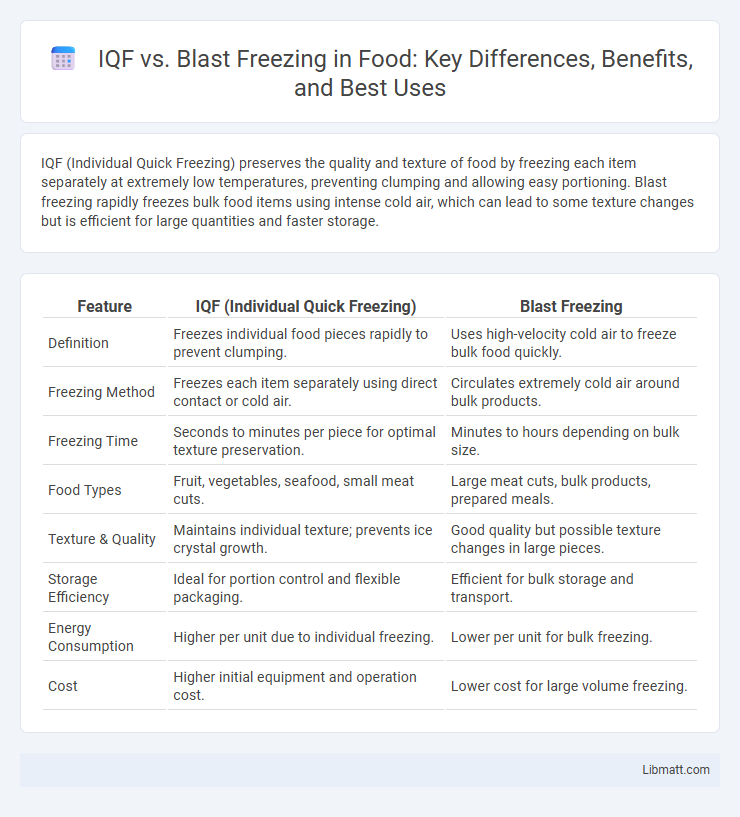

IQF (Individual Quick Freezing) preserves the quality and texture of food by freezing each item separately at extremely low temperatures, preventing clumping and allowing easy portioning. Blast freezing rapidly freezes bulk food items using intense cold air, which can lead to some texture changes but is efficient for large quantities and faster storage.

Table of Comparison

| Feature | IQF (Individual Quick Freezing) | Blast Freezing |

|---|---|---|

| Definition | Freezes individual food pieces rapidly to prevent clumping. | Uses high-velocity cold air to freeze bulk food quickly. |

| Freezing Method | Freezes each item separately using direct contact or cold air. | Circulates extremely cold air around bulk products. |

| Freezing Time | Seconds to minutes per piece for optimal texture preservation. | Minutes to hours depending on bulk size. |

| Food Types | Fruit, vegetables, seafood, small meat cuts. | Large meat cuts, bulk products, prepared meals. |

| Texture & Quality | Maintains individual texture; prevents ice crystal growth. | Good quality but possible texture changes in large pieces. |

| Storage Efficiency | Ideal for portion control and flexible packaging. | Efficient for bulk storage and transport. |

| Energy Consumption | Higher per unit due to individual freezing. | Lower per unit for bulk freezing. |

| Cost | Higher initial equipment and operation cost. | Lower cost for large volume freezing. |

Introduction to IQF and Blast Freezing

IQF (Individually Quick Frozen) technology rapidly freezes individual food items, preserving texture and nutritional value by preventing large ice crystal formation. Blast freezing uses very cold air circulated at high velocity to freeze bulk quantities quickly, maintaining product quality and extending shelf life. Your choice between IQF and blast freezing depends on desired food texture, processing volume, and storage requirements.

How IQF Freezing Works

IQF (Individually Quick Freezing) works by rapidly freezing individual pieces of food using cold air at temperatures typically between -30degC to -50degC, preventing large ice crystals from forming and preserving texture and taste. Unlike blast freezing, which freezes bulk quantities quickly, IQF ensures each item is frozen separately, maintaining product quality and avoiding clumping. This method is commonly used for fruits, vegetables, and seafood to retain freshness during storage and transport.

The Science Behind Blast Freezing

Blast freezing rapidly lowers the temperature of food to -30degC or lower, forming small ice crystals that preserve cellular structure and nutritional quality better than slower freezing methods. This rapid temperature drop minimizes the formation of large ice crystals that can damage food texture and flavor, a key advantage over IQF, which freezes individual pieces but sometimes less rapidly. Understanding this science helps you choose blast freezing for superior preservation of freshness, texture, and nutrient retention in frozen products.

Key Differences Between IQF and Blast Freezing

IQF (Individually Quick Frozen) uses rapid freezing methods that freeze each piece of food separately to prevent clumping, preserving texture and quality. Blast freezing involves exposing food to intense cold air, freezing items rapidly as a batch, which is efficient for bulk storage but may cause ice crystals to form on product surfaces. Understanding these key differences helps you choose the right freezing technique to maintain your food's integrity and shelf life.

Product Quality: Texture, Flavor, and Appearance

IQF freezing preserves product quality by freezing individual pieces rapidly, maintaining original texture, flavor, and appearance without clumping. Blast freezing uses extremely cold air to freeze products quickly, though longer exposure can sometimes cause slight texture changes and moisture loss. IQF is preferred for delicate items where maintaining natural quality attributes is critical.

Operational Efficiency and Throughput

IQF (Individually Quick Frozen) technology enables rapid freezing of individual items, significantly reducing product clumping and enhancing sorting efficiency, resulting in higher operational throughput for food processing plants. In contrast, blast freezing offers bulk freezing with higher cooling power, suitable for large volume batches but may cause slower line speeds due to longer freezing cycles and increased risk of product adhesion. Choosing IQF over blast freezing improves workflow automation, reduces labor costs, and supports just-in-time production by maintaining a consistent high-speed throughput in frozen food operations.

Energy Consumption and Cost Comparison

IQF (Individually Quick Frozen) uses targeted freezing technology that often results in lower energy consumption per kilogram compared to blast freezing, which requires more extensive cold air circulation and higher overall power to maintain ultra-low temperatures. The energy efficiency of IQF systems typically translates to reduced operational costs, making it more cost-effective for processing smaller batches or products requiring rapid freezing without clumping. On the other hand, blast freezing incurs higher energy demands and maintenance expenses, but it is more efficient for bulk freezing large volumes quickly, impacting the cost comparison depending on production scale and product type.

Applications: Best Uses for IQF and Blast Freezing

IQF (Individually Quick Frozen) technology is ideal for preserving the quality and texture of delicate foods like berries, seafood, and small vegetables by freezing items separately to prevent clumping. Blast freezing is best suited for larger bulk items such as meat cuts or baked goods, rapidly lowering temperatures to lock in moisture and maintain freshness during storage. Your choice between IQF and blast freezing depends on the specific application and product size to maximize quality and shelf life.

Food Safety Considerations

IQF (Individually Quick Frozen) preserves food quality by freezing each piece separately, reducing the risk of bacterial growth and contamination during the freezing process. Blast freezing rapidly lowers food temperature, minimizing ice crystal formation and maintaining microbial safety by preventing pathogen proliferation. Choosing the right method impacts your product's safety by ensuring proper temperature control and minimizing the potential for foodborne illnesses.

Choosing the Right Freezing Method for Your Needs

Choosing the right freezing method depends on your specific needs, such as product type, volume, and desired quality. IQF (Individually Quick Frozen) is ideal for preserving the texture and flavor of delicate items like fruits and seafood by freezing them individually, preventing clumping. Blast freezing offers rapid temperature reduction for bulk items, ensuring faster freezing times and maintaining nutritional and sensory qualities for larger batches.

IQF vs Blast Freezing Infographic

libmatt.com

libmatt.com