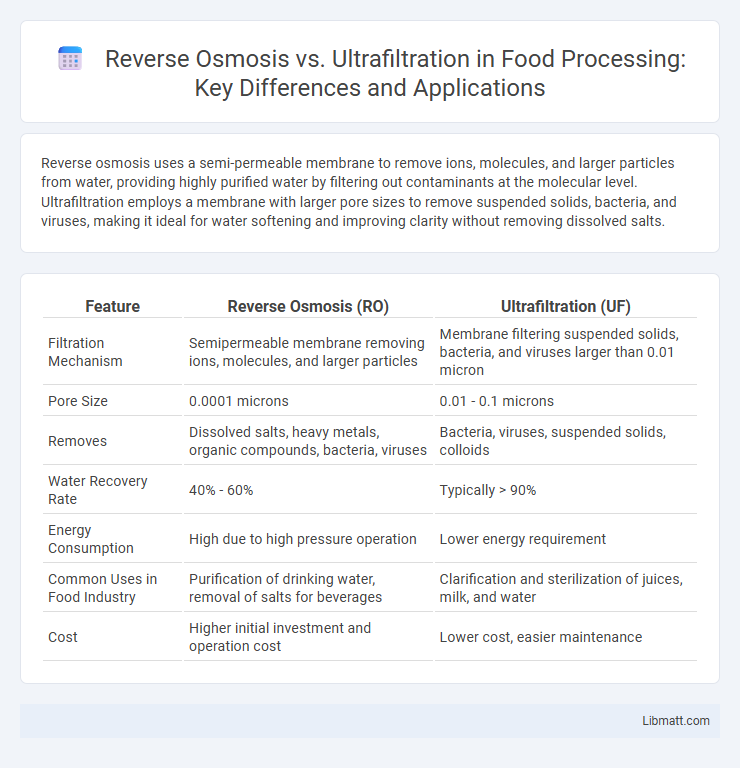

Reverse osmosis uses a semi-permeable membrane to remove ions, molecules, and larger particles from water, providing highly purified water by filtering out contaminants at the molecular level. Ultrafiltration employs a membrane with larger pore sizes to remove suspended solids, bacteria, and viruses, making it ideal for water softening and improving clarity without removing dissolved salts.

Table of Comparison

| Feature | Reverse Osmosis (RO) | Ultrafiltration (UF) |

|---|---|---|

| Filtration Mechanism | Semipermeable membrane removing ions, molecules, and larger particles | Membrane filtering suspended solids, bacteria, and viruses larger than 0.01 micron |

| Pore Size | 0.0001 microns | 0.01 - 0.1 microns |

| Removes | Dissolved salts, heavy metals, organic compounds, bacteria, viruses | Bacteria, viruses, suspended solids, colloids |

| Water Recovery Rate | 40% - 60% | Typically > 90% |

| Energy Consumption | High due to high pressure operation | Lower energy requirement |

| Common Uses in Food Industry | Purification of drinking water, removal of salts for beverages | Clarification and sterilization of juices, milk, and water |

| Cost | Higher initial investment and operation cost | Lower cost, easier maintenance |

Introduction to Reverse Osmosis and Ultrafiltration

Reverse osmosis (RO) and ultrafiltration (UF) are advanced water purification technologies that use semi-permeable membranes to remove contaminants. RO membranes have extremely fine pores that filter out dissolved salts, heavy metals, and organic molecules, making it highly effective for desalination and water softening. Ultrafiltration utilizes larger pore sizes than RO, effectively removing suspended solids, bacteria, and some viruses, but allowing dissolved ions and smaller molecules to pass through.

How Reverse Osmosis Works

Reverse osmosis works by forcing water through a semipermeable membrane that blocks contaminants such as dissolved salts, bacteria, and organic molecules, allowing only pure water molecules to pass through. This process operates under high pressure, effectively removing up to 99% of impurities, making it ideal for producing clean, safe drinking water. Your water filtration system can achieve superior purification with reverse osmosis compared to ultrafiltration, which primarily removes larger particles and pathogens but not dissolved solids.

How Ultrafiltration Works

Ultrafiltration uses a membrane with pore sizes typically between 0.01 to 0.1 microns to remove suspended solids, bacteria, viruses, and large organic molecules from water. The process relies on pressure to force water through the membrane, allowing only clean water and small dissolved substances to pass while retaining contaminants. Ultrafiltration is effective for purifying water without removing dissolved salts, unlike reverse osmosis, which removes ions and smaller molecules through a denser membrane.

Key Differences Between Reverse Osmosis and Ultrafiltration

Reverse osmosis (RO) uses a semi-permeable membrane to remove dissolved salts, heavy metals, and impurities at a molecular level, producing highly purified water. Ultrafiltration (UF) employs a membrane with larger pores to filter out suspended solids, bacteria, and viruses but allows most dissolved minerals to pass through. RO is ideal for desalination and removing chemical contaminants, whereas UF is commonly used for water softening and microbial purification without extensive mineral removal.

Filtration Efficiency and Pore Size Comparison

Reverse osmosis (RO) delivers superior filtration efficiency by removing up to 99% of dissolved solids, heavy metals, and contaminants due to its extremely fine membrane pore size of approximately 0.0001 microns. Ultrafiltration (UF) membranes feature larger pore sizes ranging from 0.01 to 0.1 microns, effectively filtering out bacteria, viruses, and suspended solids but allowing most dissolved salts and smaller molecules to pass through. RO is ideal for desalination and ultrapure water needs, while UF provides efficient microbial removal with lower operational pressure and energy costs.

Water Quality and Contaminant Removal

Reverse osmosis (RO) systems provide superior water quality by removing up to 99% of dissolved salts, heavy metals, and microscopic contaminants through a semi-permeable membrane with pore sizes around 0.0001 microns. Ultrafiltration (UF) targets larger particles, bacteria, and viruses, filtering out contaminants typically above 0.01 microns but does not remove dissolved solids or salts effectively. RO is ideal for producing high-purity water suitable for drinking and industrial use, while UF is commonly used for pre-treatment and bacterial removal.

System Installation and Maintenance Requirements

Reverse osmosis systems require higher pressure pumps and more complex plumbing for installation, often demanding professional expertise, whereas ultrafiltration units are typically easier to install with lower pressure needs and simpler piping. The maintenance of reverse osmosis membranes involves regular replacement and frequent pre-filter changes to prevent fouling, while ultrafiltration membranes generally need less frequent cleaning and have a longer lifespan due to their larger pore size and lower sensitivity to contaminants. Monitoring system performance and periodic backwashing are essential for ultrafiltration, contrasting with the frequent membrane flushing and chemical cleaning protocols necessary for reverse osmosis.

Cost Analysis: Reverse Osmosis vs Ultrafiltration

Reverse osmosis systems generally incur higher upfront and operational costs due to their complex membrane technology and energy consumption requirements, making them a more significant investment compared to ultrafiltration units. Ultrafiltration offers a cost-effective alternative with lower maintenance and energy expenses, ideal for applications where removing larger particles and certain bacteria suffices. Your choice between reverse osmosis and ultrafiltration should consider both budget constraints and the level of water purification needed.

Best Use Cases for Reverse Osmosis Systems

Reverse osmosis systems excel in removing dissolved salts, heavy metals, and contaminants from water, making them ideal for purifying drinking water in areas with high total dissolved solids (TDS). Your best use case includes producing ultrapure water for residential, commercial, and industrial applications where high water quality is essential. Reverse osmosis is also suitable for desalination and treating brackish water, providing a reliable solution for challenging water sources.

Best Applications for Ultrafiltration Systems

Ultrafiltration systems excel in applications requiring the removal of suspended solids, bacteria, viruses, and high molecular weight substances without removing dissolved salts, making them ideal for wastewater treatment, food and beverage processing, and pharmaceutical production. These systems are well-suited for clarifying water, concentrating proteins, or preparing feedwater for reverse osmosis by reducing fouling. Your choice of ultrafiltration can improve water quality and protect downstream equipment in commercial and industrial settings.

reverse osmosis vs ultrafiltration Infographic

libmatt.com

libmatt.com