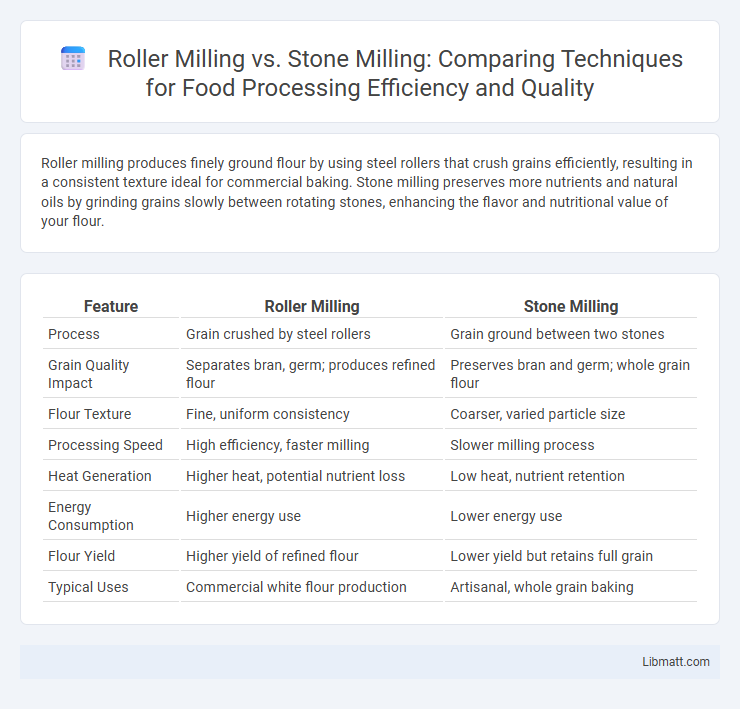

Roller milling produces finely ground flour by using steel rollers that crush grains efficiently, resulting in a consistent texture ideal for commercial baking. Stone milling preserves more nutrients and natural oils by grinding grains slowly between rotating stones, enhancing the flavor and nutritional value of your flour.

Table of Comparison

| Feature | Roller Milling | Stone Milling |

|---|---|---|

| Process | Grain crushed by steel rollers | Grain ground between two stones |

| Grain Quality Impact | Separates bran, germ; produces refined flour | Preserves bran and germ; whole grain flour |

| Flour Texture | Fine, uniform consistency | Coarser, varied particle size |

| Processing Speed | High efficiency, faster milling | Slower milling process |

| Heat Generation | Higher heat, potential nutrient loss | Low heat, nutrient retention |

| Energy Consumption | Higher energy use | Lower energy use |

| Flour Yield | Higher yield of refined flour | Lower yield but retains full grain |

| Typical Uses | Commercial white flour production | Artisanal, whole grain baking |

Introduction to Roller Milling and Stone Milling

Roller milling uses steel rollers to crush and grind grains into flour, providing consistent particle size and higher extraction rates, which enhances baking performance. Stone milling employs large, circular stones to grind grains slowly, preserving more natural oils, nutrients, and flavor profiles for artisanal quality. Your choice between these methods impacts flour texture, nutritional content, and product authenticity.

Historical Development of Milling Methods

Roller milling revolutionized grain processing in the late 19th century, replacing traditional stone milling by using a series of metal rollers to efficiently grind grain and separate bran and germ, increasing flour yield and quality. Stone milling, an ancient method dating back thousands of years, relies on two circular stones grinding grain through pressure and friction, preserving more nutrients but producing coarser flour. Your choice between these methods depends on whether you prioritize historical tradition and nutritional richness or modern efficiency and consistency.

How Roller Mills Work: Principles and Process

Roller mills operate by passing grains between pairs of rotating cylindrical rollers that crush and grind the material into finer particles. The adjustable spacing and differential roller speeds enable precise control over the particle size and texture, optimizing flour extraction and quality. This mechanized process allows for efficient separation of bran, germ, and endosperm components, enhancing yield and consistency compared to traditional milling methods.

Stone Milling: Traditional Techniques and Practices

Stone milling employs centuries-old techniques involving large, circular stones that slowly grind grains to preserve natural nutrients and enhance flavor complexity. This traditional practice maintains the germ and bran integrity, resulting in whole grain flours rich in fiber and essential oils. Unlike roller milling, stone milling operates at lower temperatures, reducing nutrient loss and yielding a coarser, more textured product favored in artisanal baking and heritage grain preservation.

Nutritional Impact: Comparing Grain Quality

Stone milling preserves the bran and germ, retaining higher fiber, vitamins, and minerals essential for better nutritional quality in whole grain flour. Roller milling often separates these components, producing finer flour with reduced nutrient density but longer shelf life. Studies show stone-milled grains contain more antioxidants and essential fatty acids, contributing to improved health benefits compared to roller-milled counterparts.

Texture and Flavor Differences in Milled Flour

Roller milling produces flour with a fine, consistent texture by quickly breaking grains into uniform particles, ideal for light, airy baked goods. Stone milling grinds grains slowly between two stones, preserving bran, germ, and natural oils, resulting in a coarser texture with richer, nutty flavors. This preservation of nutrients and complex flavor profiles in stone-milled flour enhances the taste and nutritional value of whole grain products.

Industrial Efficiency: Output and Scalability

Roller milling delivers higher industrial efficiency with increased output due to its rapid processing and consistent particle size control, supporting large-scale commercial production. Stone milling offers lower throughput and is less scalable because of slower grinding speeds and maintenance requirements. The choice between the two methods hinges on balancing scalability needs and desired flour characteristics for specific industrial applications.

Environmental Considerations of Each Milling Method

Stone milling uses traditional grinding methods that require less energy and preserve grain nutrients, making it an eco-friendly option with a smaller carbon footprint. Roller milling relies on high-speed steel rollers, consuming more electricity and generating more heat, which can impact the environment negatively through higher energy demands. When choosing your milling method, consider the environmental impact to support sustainable grain processing practices.

Cost Analysis: Investment and Operational Expenses

Roller milling demands a higher initial investment due to advanced machinery and automation but offers lower operational costs through energy efficiency and faster processing speeds. Stone milling features lower upfront expenses with simpler equipment, yet incurs higher ongoing costs related to maintenance, slower throughput, and increased labor intensity. Evaluating total cost of ownership reveals roller milling as more cost-effective for large-scale production, while stone milling suits artisanal or small-batch operations with less financial commitment.

Choosing the Right Milling Method for Your Needs

Roller milling offers high efficiency and precision, making it ideal for large-scale production with consistent particle size and reduced heat generation, preserving flour quality. Stone milling retains more nutrients and natural flavors by slowly grinding grains between stones, favored by artisanal bakeries and health-focused consumers seeking whole grain benefits. Selecting the right milling method depends on desired flour texture, production volume, and nutritional priorities to achieve optimal baking results.

Roller Milling vs Stone Milling Infographic

libmatt.com

libmatt.com