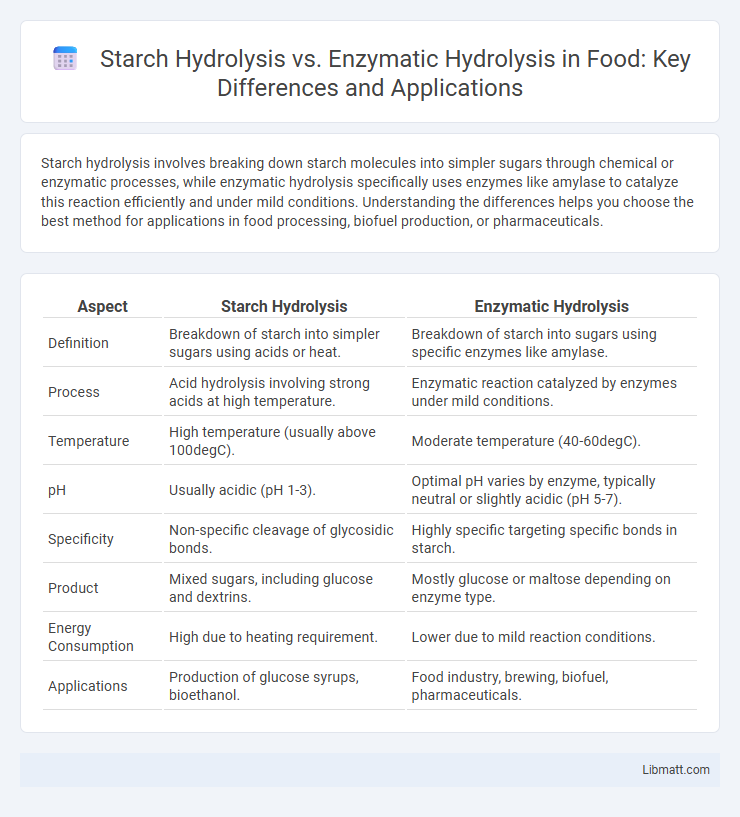

Starch hydrolysis involves breaking down starch molecules into simpler sugars through chemical or enzymatic processes, while enzymatic hydrolysis specifically uses enzymes like amylase to catalyze this reaction efficiently and under mild conditions. Understanding the differences helps you choose the best method for applications in food processing, biofuel production, or pharmaceuticals.

Table of Comparison

| Aspect | Starch Hydrolysis | Enzymatic Hydrolysis |

|---|---|---|

| Definition | Breakdown of starch into simpler sugars using acids or heat. | Breakdown of starch into sugars using specific enzymes like amylase. |

| Process | Acid hydrolysis involving strong acids at high temperature. | Enzymatic reaction catalyzed by enzymes under mild conditions. |

| Temperature | High temperature (usually above 100degC). | Moderate temperature (40-60degC). |

| pH | Usually acidic (pH 1-3). | Optimal pH varies by enzyme, typically neutral or slightly acidic (pH 5-7). |

| Specificity | Non-specific cleavage of glycosidic bonds. | Highly specific targeting specific bonds in starch. |

| Product | Mixed sugars, including glucose and dextrins. | Mostly glucose or maltose depending on enzyme type. |

| Energy Consumption | High due to heating requirement. | Lower due to mild reaction conditions. |

| Applications | Production of glucose syrups, bioethanol. | Food industry, brewing, biofuel, pharmaceuticals. |

Introduction to Starch Hydrolysis

Starch hydrolysis involves breaking down complex carbohydrates into simpler sugars through enzymatic reactions primarily catalyzed by amylases. This biochemical process is essential in industries such as biofuel production, food processing, and brewing, where starch from sources like corn, wheat, or potatoes is converted into fermentable sugars. Enzymatic hydrolysis specifically utilizes enzymes like a-amylase and glucoamylase to optimize the degradation of starch into glucose units efficiently.

Understanding Enzymatic Hydrolysis

Enzymatic hydrolysis breaks down starch into simpler sugars using specific enzymes like amylase, allowing more efficient conversion compared to starch hydrolysis alone. This process enhances bioavailability by targeting glycosidic bonds, enabling Your body or industrial applications to utilize the resulting glucose or maltose more effectively. Optimizing enzymatic hydrolysis conditions--such as temperature, pH, and enzyme concentration--maximizes sugar yield and improves overall efficiency in starch processing.

Key Differences Between Starch and Enzymatic Hydrolysis

Starch hydrolysis primarily involves the breakdown of starch molecules into simpler sugars through chemical or enzymatic processes, whereas enzymatic hydrolysis specifically refers to the catalysis of substrate degradation by enzymes like amylase. Starch hydrolysis can include acid hydrolysis, which uses chemicals, but enzymatic hydrolysis is more selective, efficient, and operates under milder conditions. Key differences lie in reaction specificity, rate, and environmental impact, with enzymatic hydrolysis offering higher precision in converting starch into glucose or maltose.

Chemical Mechanisms Involved

Starch hydrolysis involves the breakdown of polysaccharides into simpler sugars primarily through acid or enzymatic action, where acids catalyze glycosidic bond cleavage via protonation, while enzymatic hydrolysis employs amylases that specifically target alpha-1,4 and alpha-1,6 glycosidic bonds through catalytic residues in their active sites. Enzymatic hydrolysis offers higher specificity and milder reaction conditions compared to chemical hydrolysis, making it more efficient for producing glucose, maltose, and dextrins. Understanding these chemical mechanisms can help you optimize starch conversion processes in applications such as biofuel production and food industry.

Role of Enzymes in Hydrolysis Processes

Enzymes such as amylases play a crucial role in starch hydrolysis by breaking down complex starch molecules into simpler sugars like maltose and glucose through specific cleavage of glycosidic bonds. In enzymatic hydrolysis, tailored enzymes target polysaccharides more efficiently, enabling controlled conversion of substrates into desired monosaccharides or oligosaccharides under mild reaction conditions. The specificity and activity of hydrolytic enzymes significantly enhance reaction rates and product yields compared to non-enzymatic methods, making enzymatic hydrolysis essential for industrial applications such as biofuel production and food processing.

Industrial Applications and Efficiency

Starch hydrolysis primarily serves industries like food processing, bioethanol production, and paper manufacturing by converting starch into simpler sugars through acid or enzymatic methods, with enzymatic hydrolysis offering higher specificity and efficiency due to enzymes like amylase. Enzymatic hydrolysis is preferred in biofuel and pharmaceutical sectors for its milder reaction conditions and reduced by-product formation, enhancing yield and purity. Your choice between starch hydrolysis and enzymatic hydrolysis depends on the desired product quality, processing time, and cost-effectiveness in industrial applications.

Environmental and Economic Impacts

Starch hydrolysis relies on acid or heat treatments that consume significant energy and generate hazardous waste, posing environmental concerns and increasing disposal costs. Enzymatic hydrolysis uses amylase enzymes, reducing chemical usage and energy consumption, thereby minimizing carbon emissions and effluent treatment expenses. Economically, enzymatic hydrolysis offers higher efficiency and specificity, lowering operational costs and enhancing sustainability in industrial applications.

Advantages and Limitations of Each Method

Starch hydrolysis offers advantages such as simplicity and cost-effectiveness, making it suitable for industrial applications requiring bulk conversion of starch into sugars. Enzymatic hydrolysis provides higher specificity and milder operating conditions, leading to better control over product yield and purity but often demands higher costs and longer processing times due to enzyme requirements. Your choice between these methods depends on factors like desired product quality, processing scale, and available resources.

Case Studies and Real-world Examples

Case studies of starch hydrolysis highlight its application in bioethanol production, where enzymes like amylase break down corn starch into fermentable sugars, optimizing yield and process efficiency. Enzymatic hydrolysis has been utilized in food industries, such as converting starch in potatoes to glucose syrups, demonstrating improved product consistency and cost-effectiveness compared to acid hydrolysis. Real-world examples include its role in paper manufacturing, where enzymatic hydrolysis enhances fiber modification, leading to better paper strength and reduced environmental impact.

Future Trends in Hydrolysis Technologies

Future trends in hydrolysis technologies emphasize enhanced enzyme engineering and the integration of advanced biocatalysts to improve starch hydrolysis efficiency. Enzymatic hydrolysis benefits from developments in immobilized enzyme systems and genetically modified microbes, enabling higher yield and specificity under milder conditions compared to traditional acid-based starch hydrolysis. Innovations in process intensification and hybrid hydrolysis techniques are poised to optimize biofuel production and bioplastic manufacturing by reducing energy consumption and minimizing environmental impact.

Starch Hydrolysis vs Enzymatic Hydrolysis Infographic

libmatt.com

libmatt.com